Hydraulic double-acting drilling reamer

A double-acting, hydraulic technology, applied to drilling equipment, drill bits, earthwork drilling and production, etc., can solve problems such as inability to effectively complete hole reaming operations and low work safety, and achieve improved work safety, high work reliability, Ensuring the effect of cooling the cutting teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

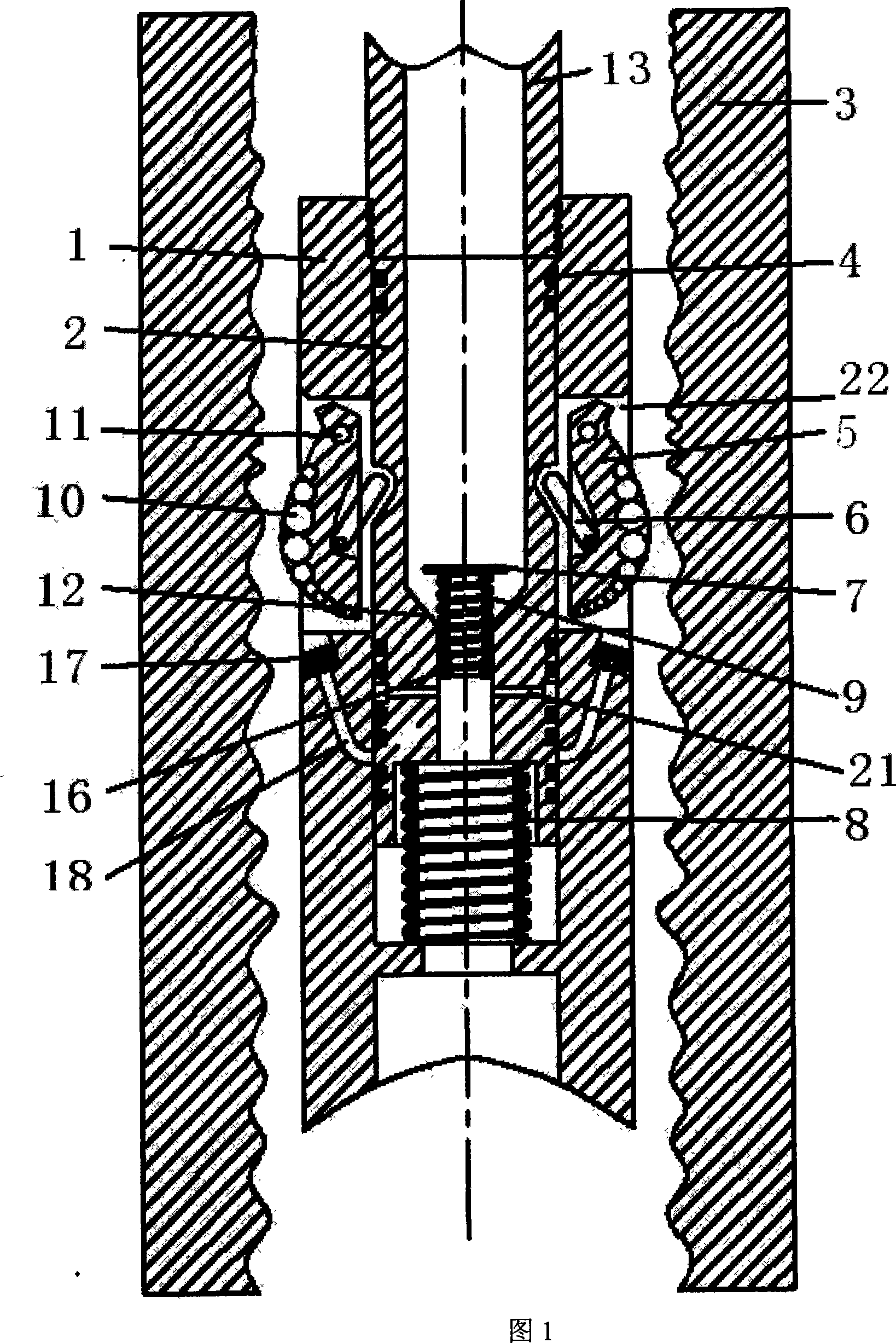

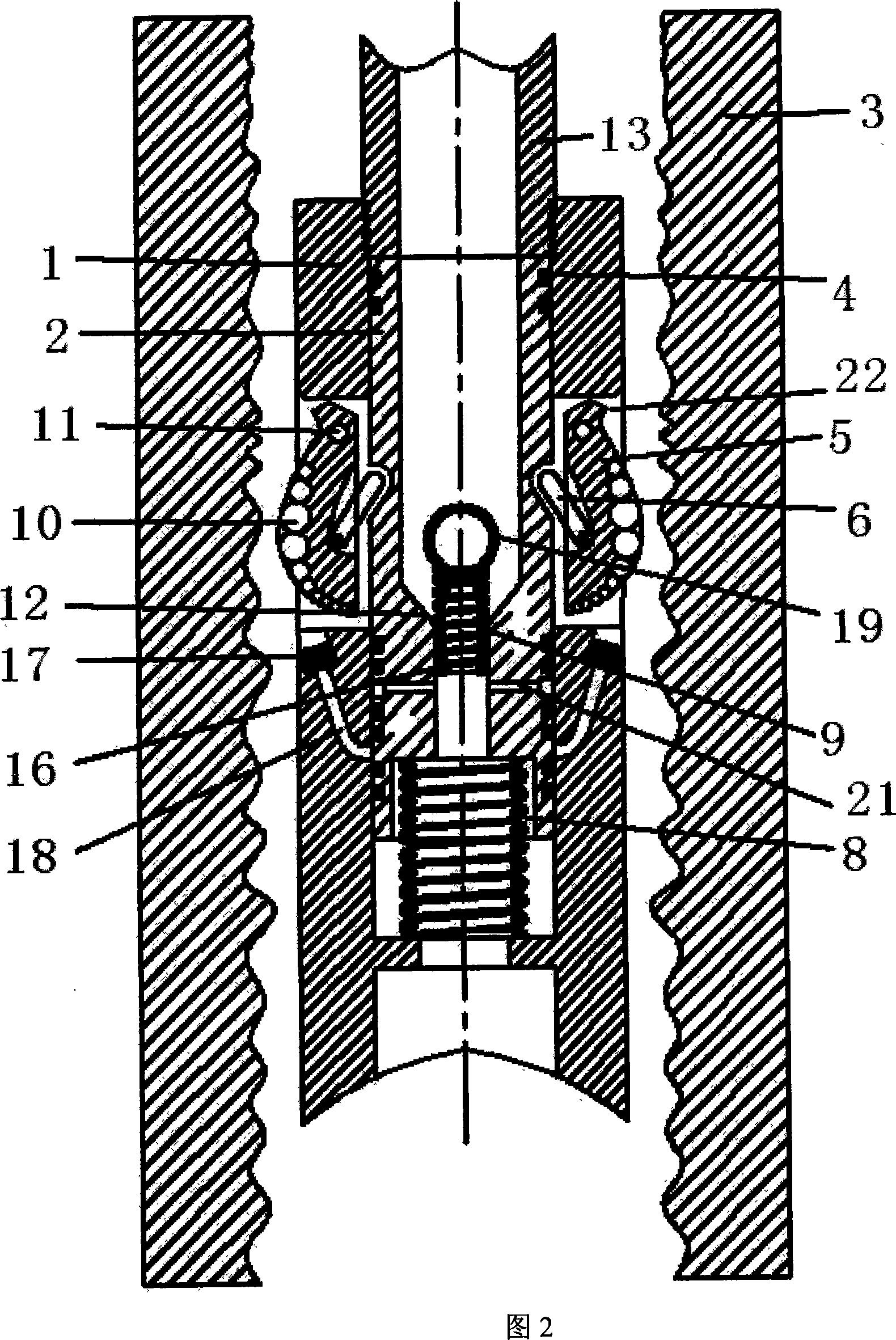

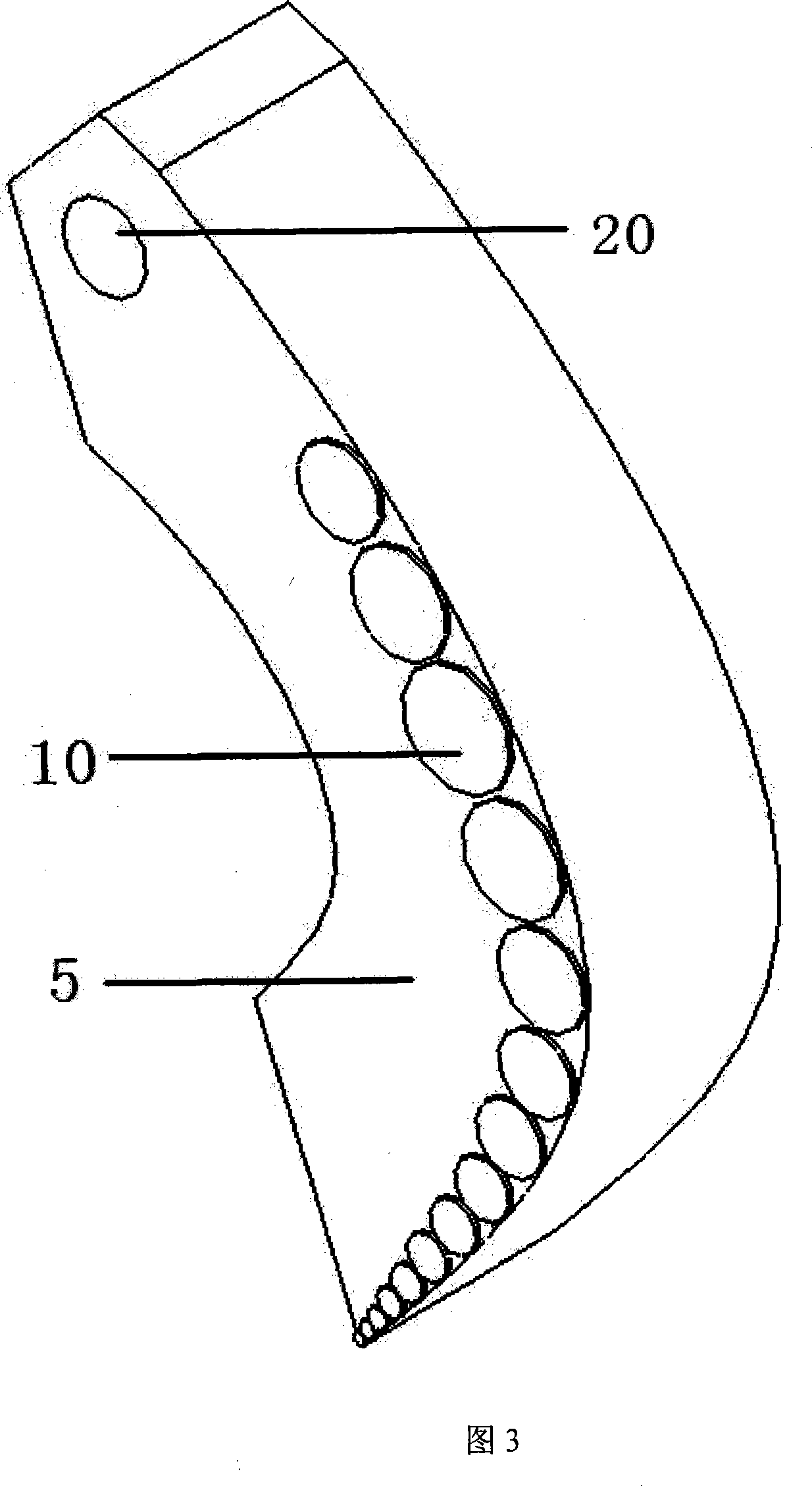

[0013] As shown in Fig. 1, Fig. 2 and Fig. 3, when the reamer is not working, the reaming blade 5 is retracted and remains in the state as shown in the figure. The lower end of the central tube 2 is provided with a tapered flow port 12, and the flow area of the flow port is large and the head loss is small when the displacement is normal. When the displacement is increased, the compression of the spring 9 increases, the valve plate 7 (or valve ball 19) contacts the slope of the overflow port 12, the flow area of the overflow port decreases, and the pressure head loss is large, resulting in a large flow For the downward thrust, the stiffness of the spring is reasonably set so that the downward thrust is greater than the supporting force of the spring 9, and under the action of the thrust, the central tube 2 moves downward in the axial direction. The central tube 2 moving downward pushes the crank 6 to move downward, and the blade 5 is connected to the body 1 through the pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com