On-site overhaul process of oversize transformer

A transformer and extra-large technology, applied in the field of super-large transformer on-site overhaul process, can solve the problems of inability to effectively improve the insulation performance of the transformer, enhance the short-circuit resistance of the transformer, and the pressure plate cannot be pressed down at the same time, so as to reduce the level of partial discharge and performance. Reliable, the effect of improving the ability to resist short-circuit shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

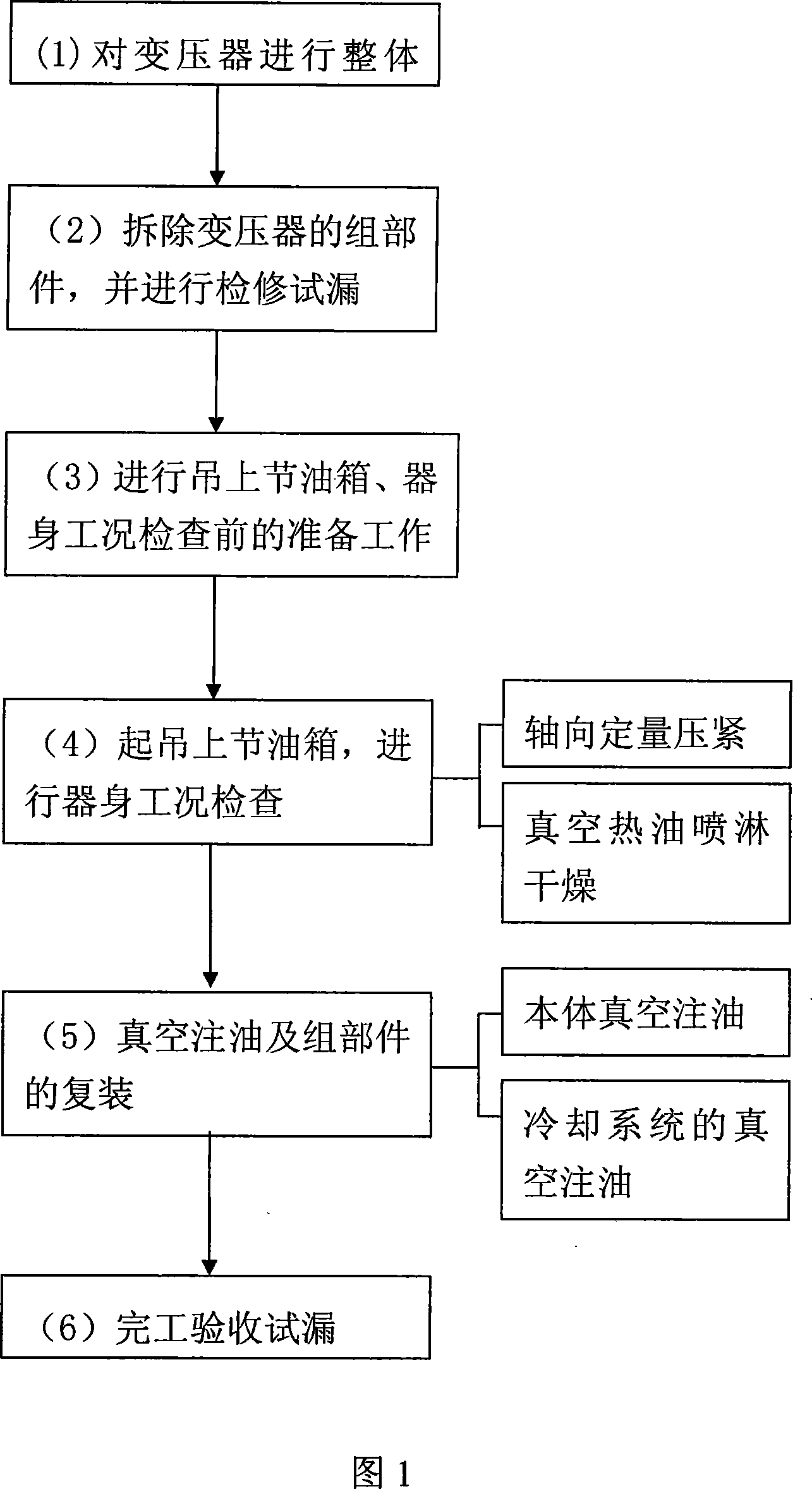

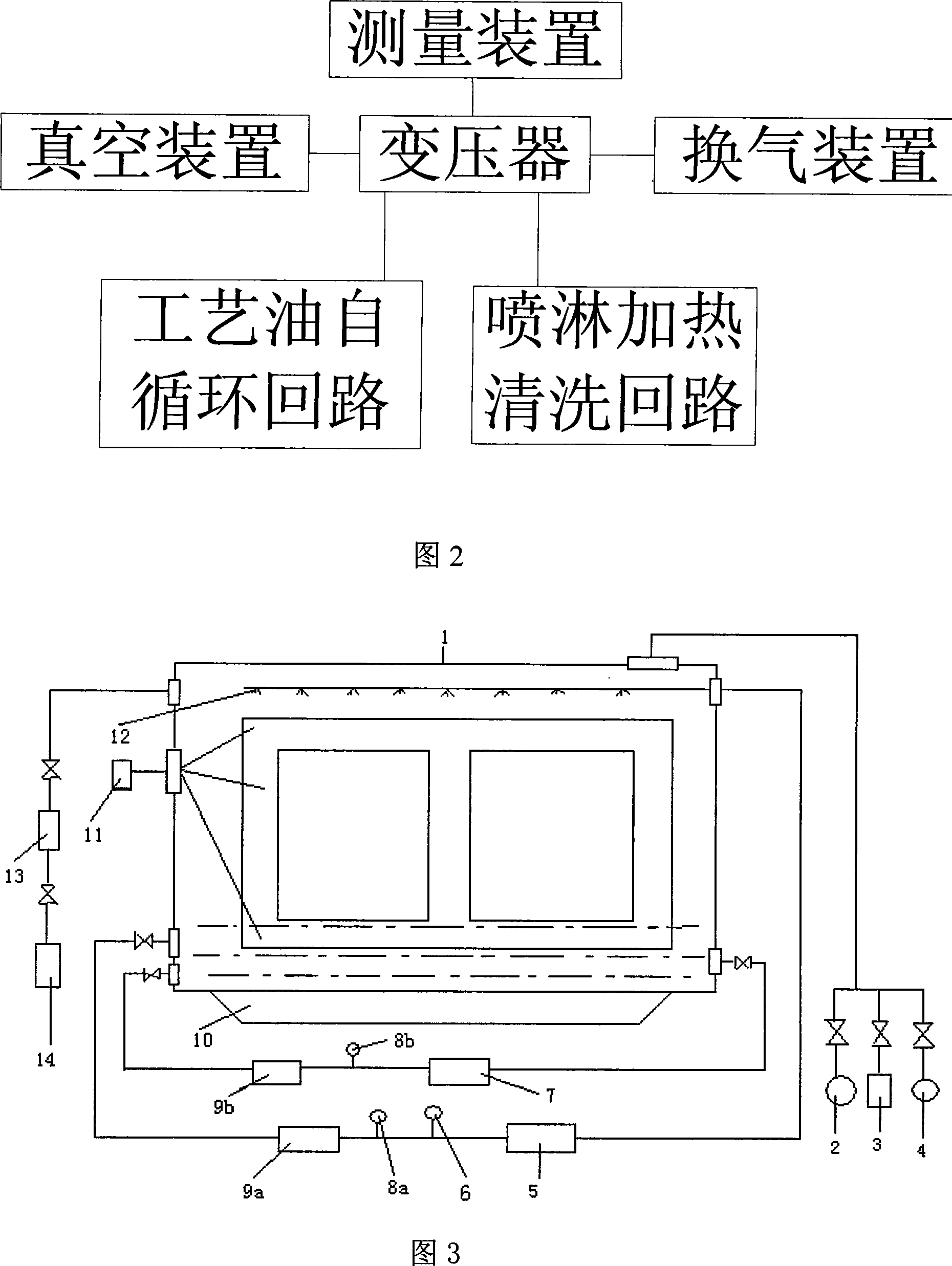

[0044] Embodiment: a kind of extra-large transformer on-site overhaul process (seeing Fig. 1), comprises the following steps:

[0045] 1. Carry out an overall leak test on the transformer: add air pressure to the oil conservator, check the leaking part, and mark it for processing during overhaul;

[0046] 2. Remove the components of the transformer and carry out maintenance: when removing the bushing and other components, blow dry air into the transformer oil tank to help reduce the degree of moisture in the transformer body; the maintenance of each component of the transformer shall be in accordance with the manufacturer's process documents , guidelines and specifications, and modify components according to the requirements of anti-accident measures;

[0047] 3. Preparatory work before lifting the fuel-saving tank and inspecting the working condition of the body:

[0048] ①Hot oil circulation: heat the body to make it higher than the ambient temperature to prevent condensati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com