Shrapnel on circuit board and electromagnetic shielding assembly

A technology of circuit boards and shrapnel, applied in the direction of magnetic field/electric field shielding, printed circuit, circuit arrangement on support structure, etc., can solve problems such as fracture, shrapnel 2 damage, bending, etc., to avoid bending deformation or fracture, and ensure Elasticity, the effect of avoiding tin creeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

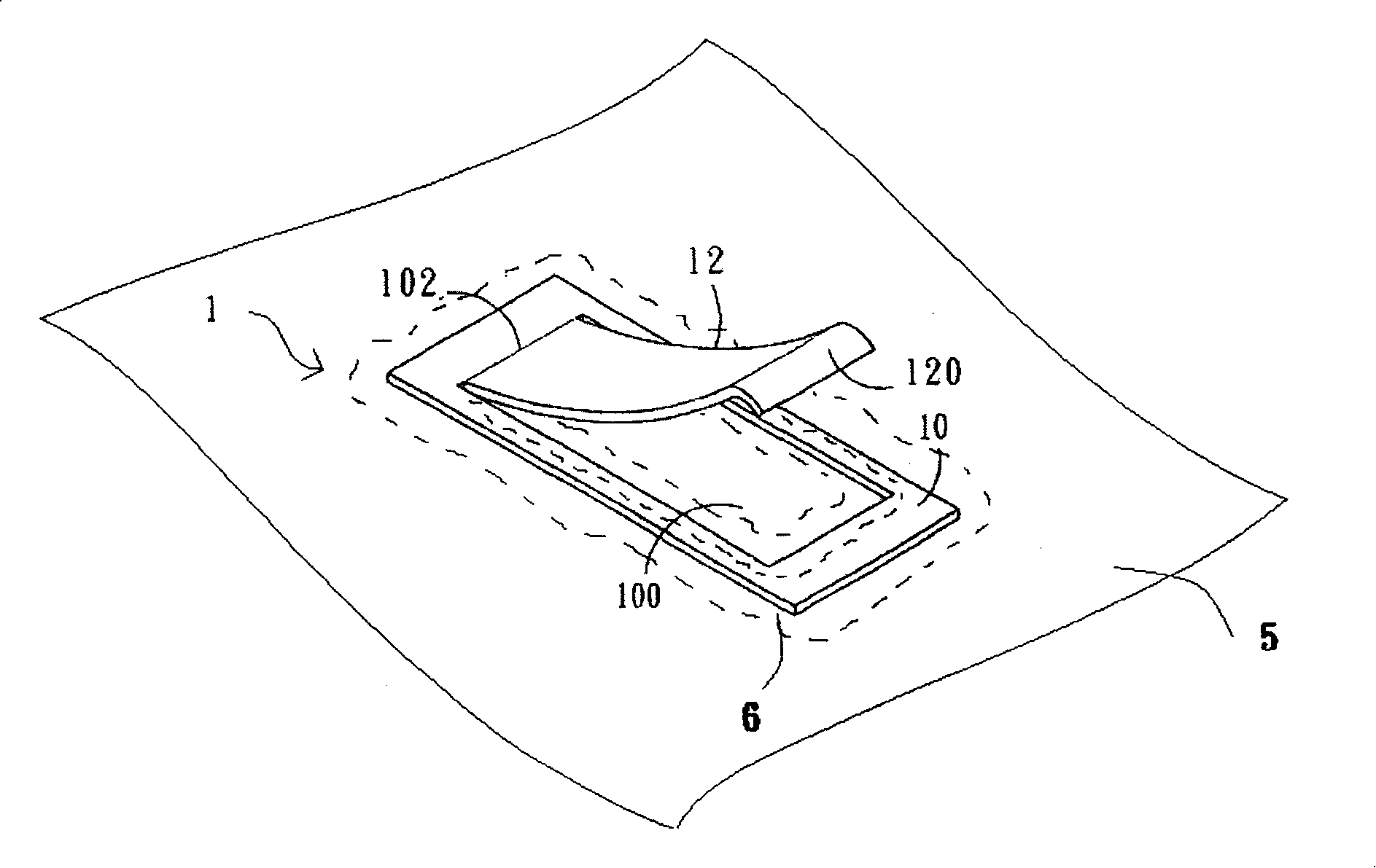

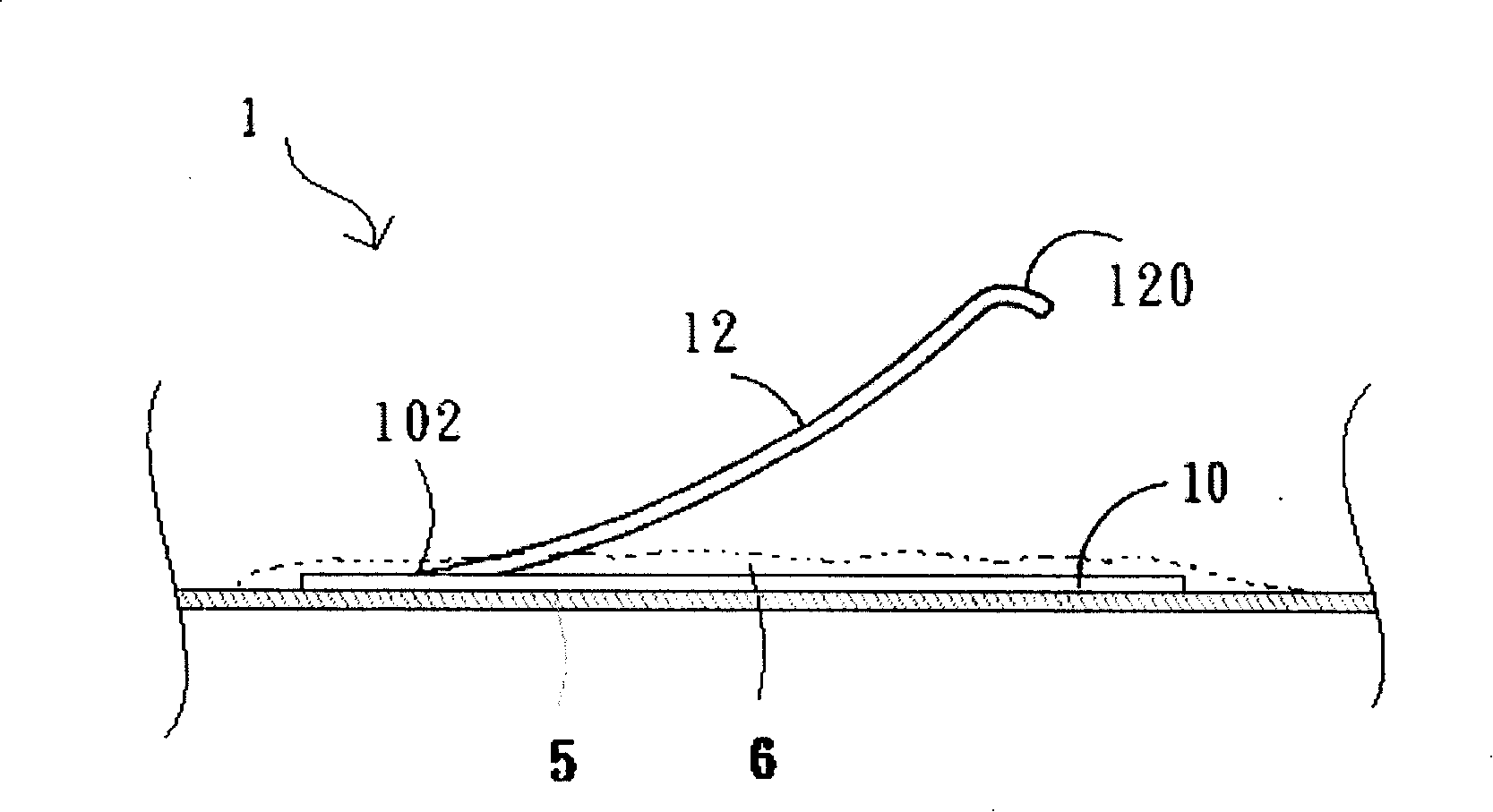

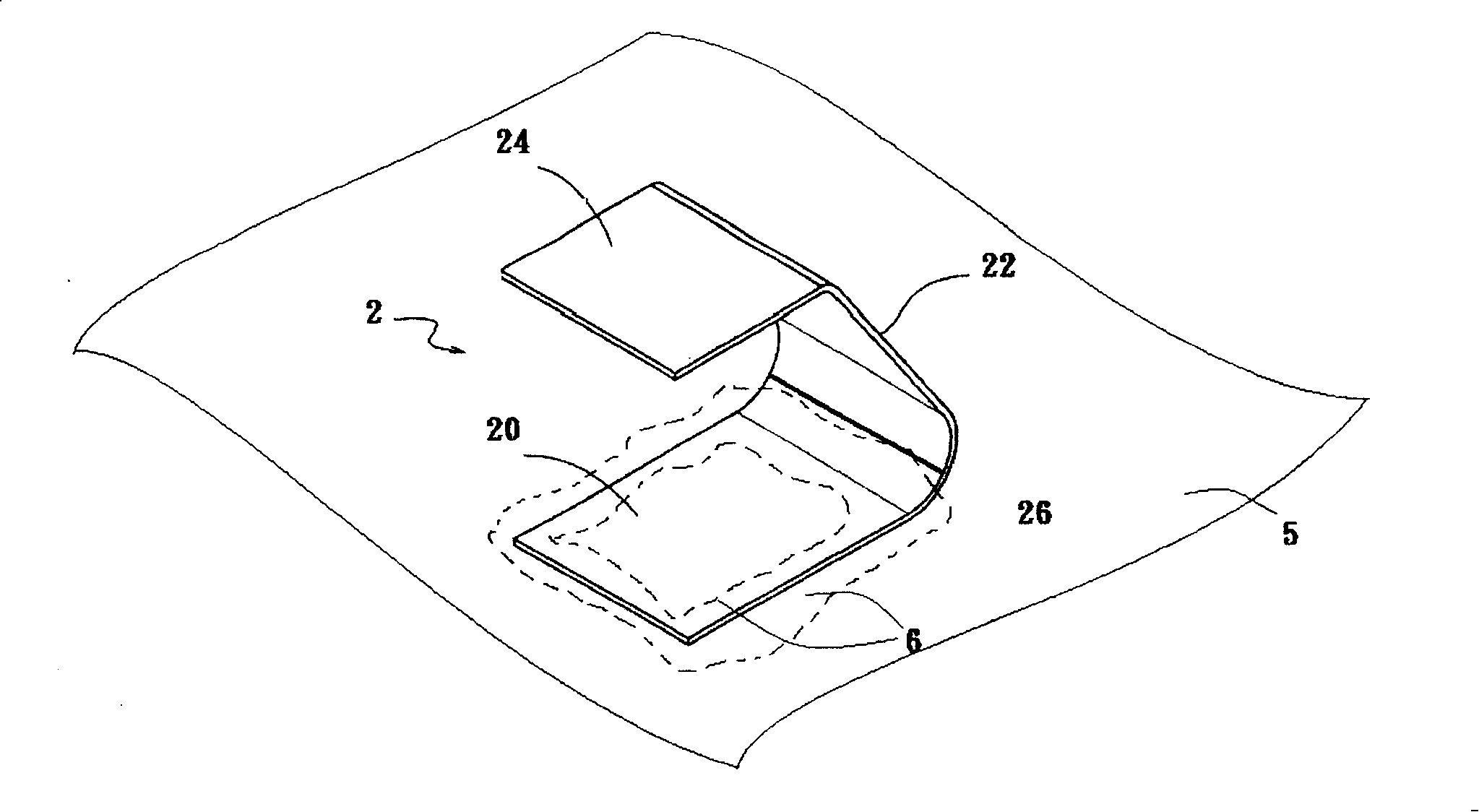

[0030] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description in conjunction with preferred embodiments and accompanying drawings.

[0031] Such as Figure 4-7 As shown, the shrapnel 3 on the circuit board provided by a preferred embodiment of the present invention is an integrally formed metal sheet, which includes a shrapnel body 31, and the upper and lower sides of the shrapnel body 31 are two opposite wings 310 (such as Figure 4 As shown), the two side wings adjacent to the left and right sides are two end edges 312. In this embodiment, the side wings 310 and the end edges 312 are perpendicular to each other to form a rectangle; Arm 32; a welding section 30 is folded downwards from two opposite side wings 310 of the spring body 31, and the welding section 30 can be divided into a welding base 300 corresponding to the spring body 31 and a welding base 300 extending from the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com