Polyvinylidene chloride resin composition, biaxially stretched film, and method for producing such biaxially stretched film

A resin compound and vinylidene chloride technology, applied in the field of biaxially stretched films and poly1, can solve the problems of increased number of defects, interlayer peeling, insufficient and so on, and achieve the effect of prolonging the continuous running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

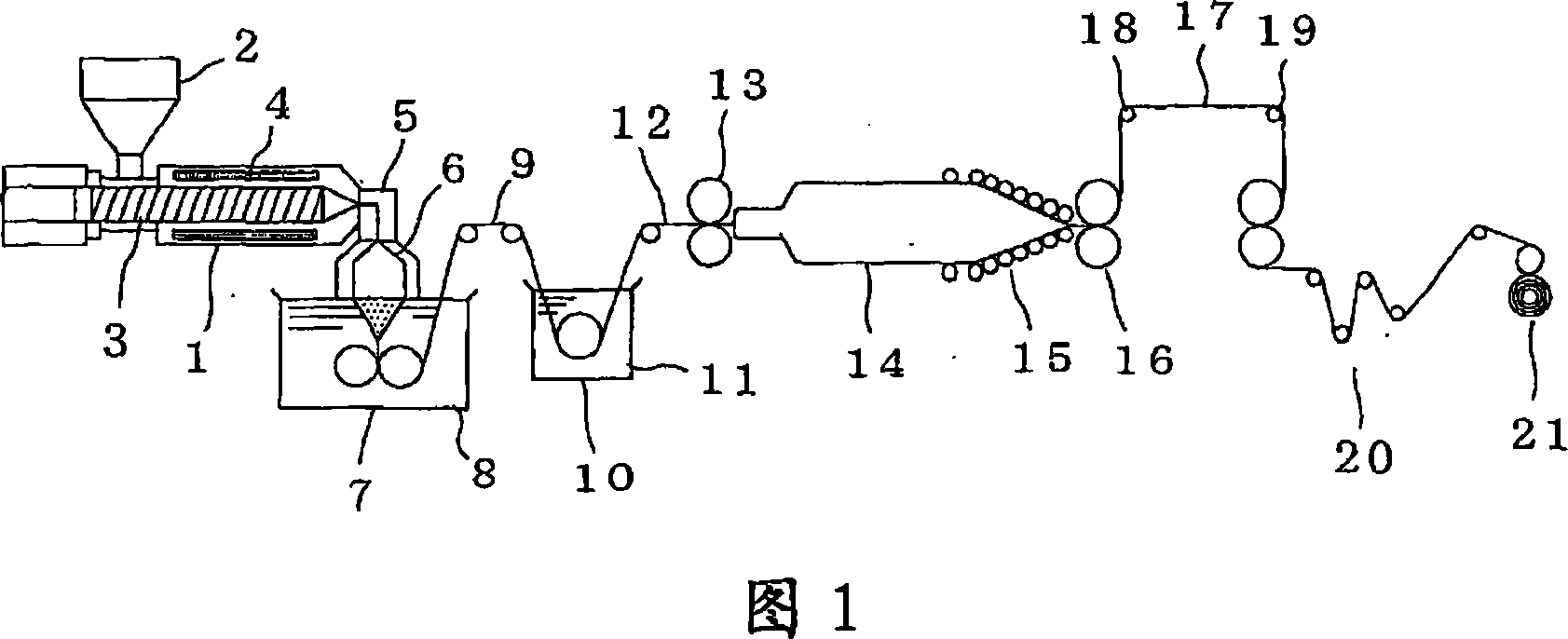

Image

Examples

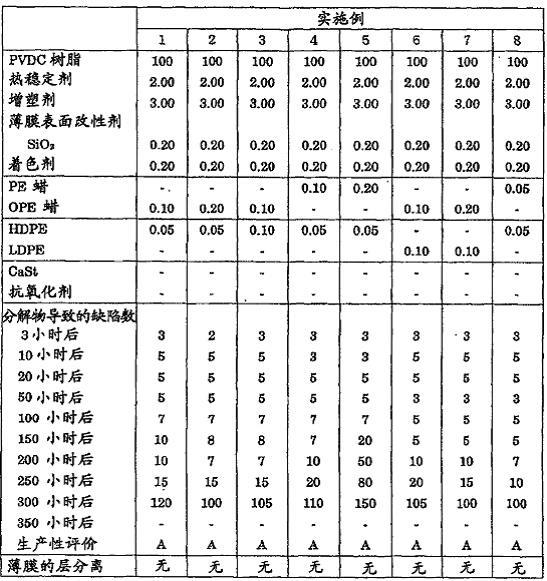

Embodiment 1

[0131] (1) Modulation of the complex

[0132] As PVDC resin, 1,1-dichloroethylene-vinyl chloride copolymer (1,1-dichloroethylene / vinyl chloride=88 / 12% by weight, reduced viscosity=0.058 liter / g) obtained by suspension polymerization method was used powder resin (particle size = 442 μm).

[0133] In the blade mixer, add 100 parts by weight of powdered resin, 2.00 parts by weight of heat stabilizer (epoxidized linseed oil), 3.00 parts by weight of plasticizer (dibutyl sebacate), 0.20 parts by weight thin film surface modifier [silicon dioxide (SiO 2 ); produced by Mizusawa Chemical Industry Co., Ltd., trade name "Silhonait M-1"], 0.20 parts by weight of coloring agent (pigment red 166 produced by Dainichi Seika Co., Ltd.), 0.10 parts by weight of oxidized polyethylene wax (OPE wax; manufactured by Honeywell Co., Ltd. , trade name "Honeywell A-C629A"; melt viscosity=200mPa·s, density=0.930g / cm 3 , melting point=95°C, acid value=16KOHmg / g), and 0.05 parts by weight of high-dens...

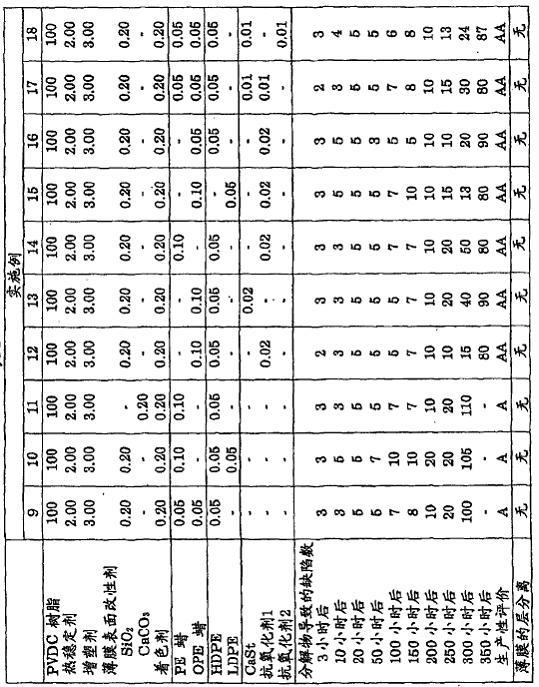

Embodiment 2~18

[0137] The biaxially stretched film was continuously produced in the same manner as in Example 1, except that the types and compounding ratios of various additive components were changed as shown in Tables 1 and 2. PVDC resin (powder resin), heat stabilizer, plasticizer, film surface modifier, and coloring agent, are identical with embodiment 1 prescription.

[0138] However, in Example 11, calcium carbonate was used instead of silica as a film surface modifier. Oxidized polyethylene wax (OPE wax) and high-density polyethylene (HDPE) were the same as in Example 1.

[0139] The additive components not used in Example 1 are as follows.

[0140] (1) Polyethylene wax (PE wax): manufactured by Honeywell, trade name "Honeywell A-C617", melt viscosity = 180 mPa·s, density = 0.910 g / cm 3 , melting point = 97°C;

[0141] (2) Low-density polyethylene (LDPE): manufactured by Mitsui Chemicals, trade name "Mirason", density = 0.921 g / cm 3 , melting point=109°C, MFR=3.3g / 10min;

[0142...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com