Assembled disintegrator

A pulverizer and combined technology, applied in the direction of grain processing, etc., can solve the problems of wasting energy, only finely crushing, polluting the environment, etc., to reduce the volume of equipment, meet the requirements of granulation fineness, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

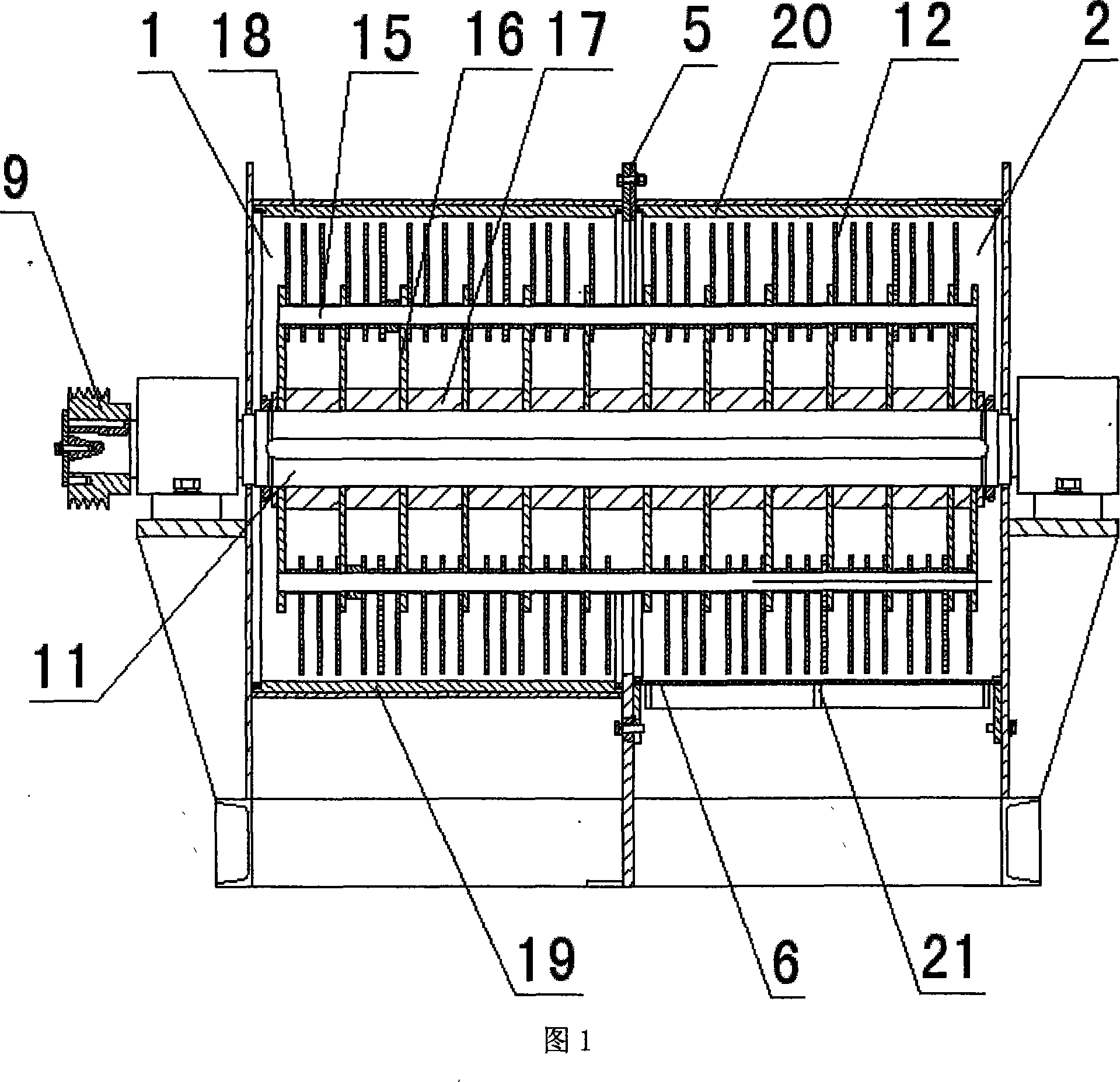

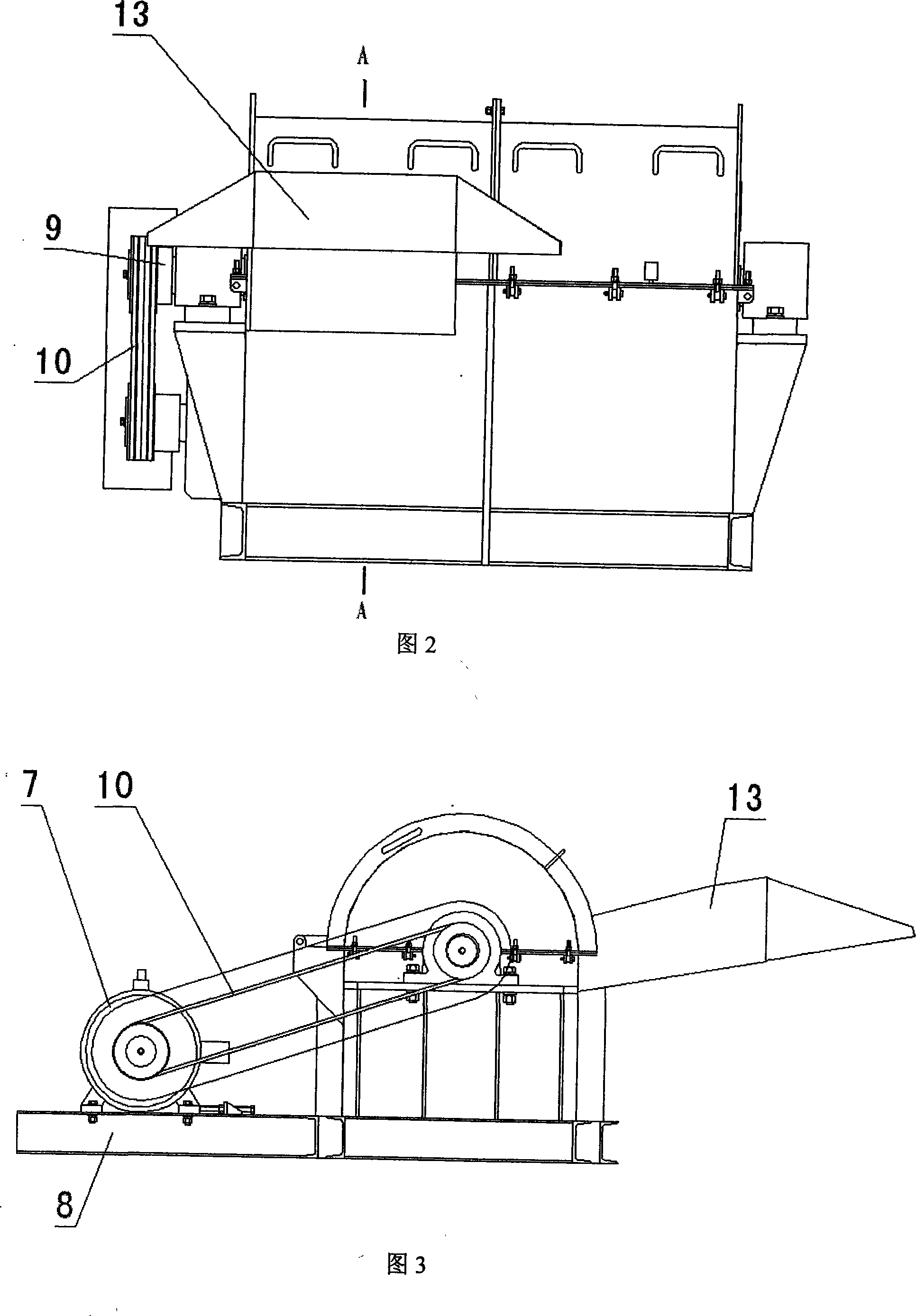

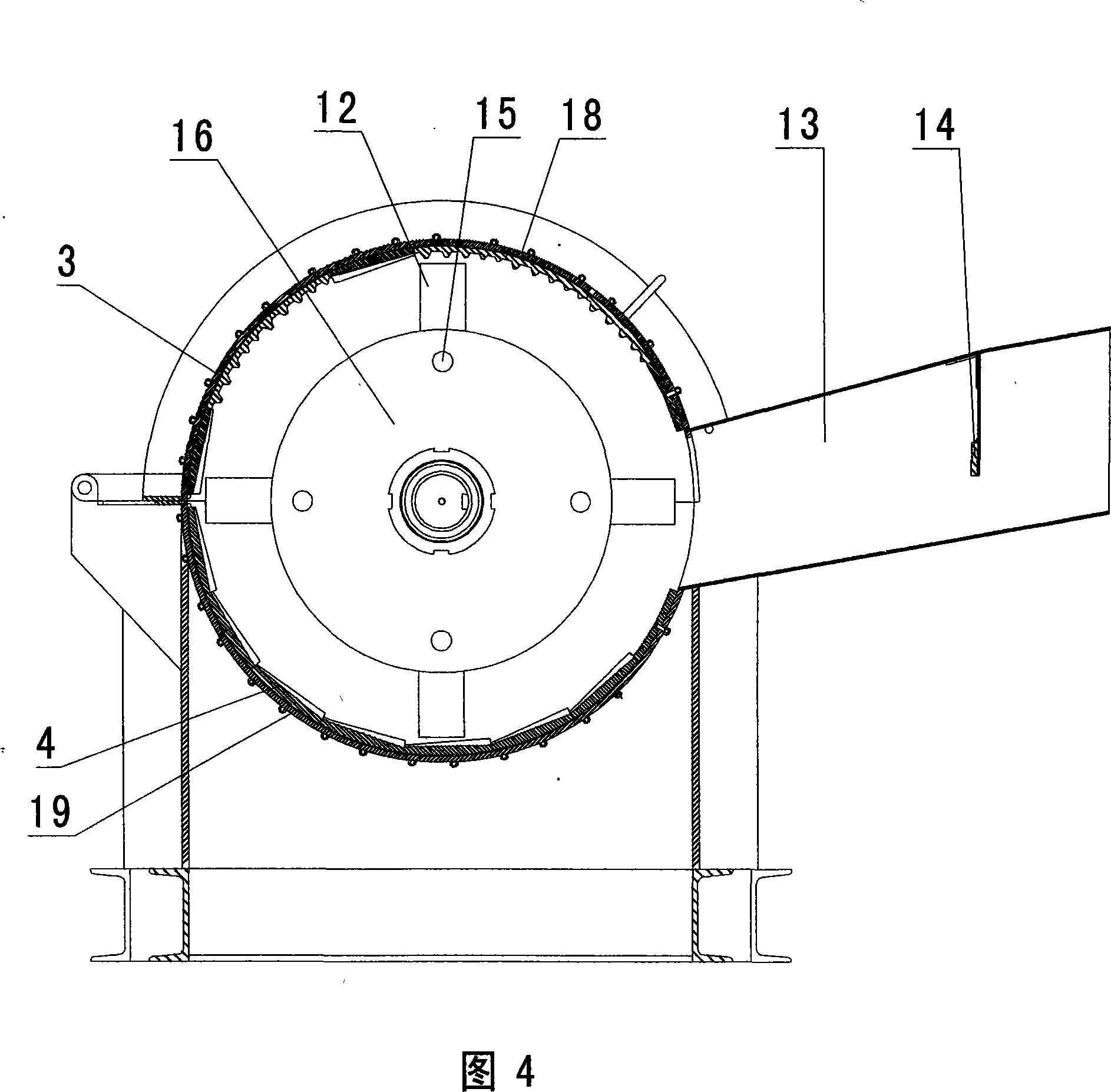

[0019] In the embodiment shown in Figure 1, Figure 2, Figure 3, and Figure 4, a combined pulverizer is provided with a kneading chamber and a crushing chamber, and the housing includes an upper left housing 18, a lower left housing 19, and an upper right housing. 20, the lower right housing 21, the left and right side plates. The upper left housing 18 and the lower left housing 19 form the left housing, and the left housing is provided with a feed inlet 13, and a movable gravity safety door 14 is arranged in the feed inlet 13; a straight tooth plate 3 is installed on the inner side of the upper left housing 18 and the helical tooth plate, the helical tooth plate 4 is installed on the inner side of the left lower housing; the right upper housing 20 and the right lower housing 21 form the right housing; the straight tooth plate and the helical tooth plate are also installed on the inner side of the right upper housing 20, A screen 6 is installed inside the lower right housing 21...

Embodiment 2

[0021] Hammers of pulverizers are vulnerable parts, and damaged hammers may often need to be replaced. In order to facilitate the replacement of hammers, the hammer pin shafts distributed uniformly on the hammer frame plate are set as two shorter hammer pin shafts, so that the When replacing the damaged hammer piece, just remove the short hammer pin shaft where the broken hammer piece is located to replace it, avoiding the removal of the long hammer pin shaft 15 in Embodiment 1; other mechanisms are exactly the same as in Embodiment 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com