Method of preparing graded cementing and colour separation pile coating and special hardware thereof

A technology of color separation and flocking, special equipment, applied in dyeing method, textile decoration, device for coating liquid on the surface, etc., to achieve the effect of high work efficiency, considerable benefit and accurate flower position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

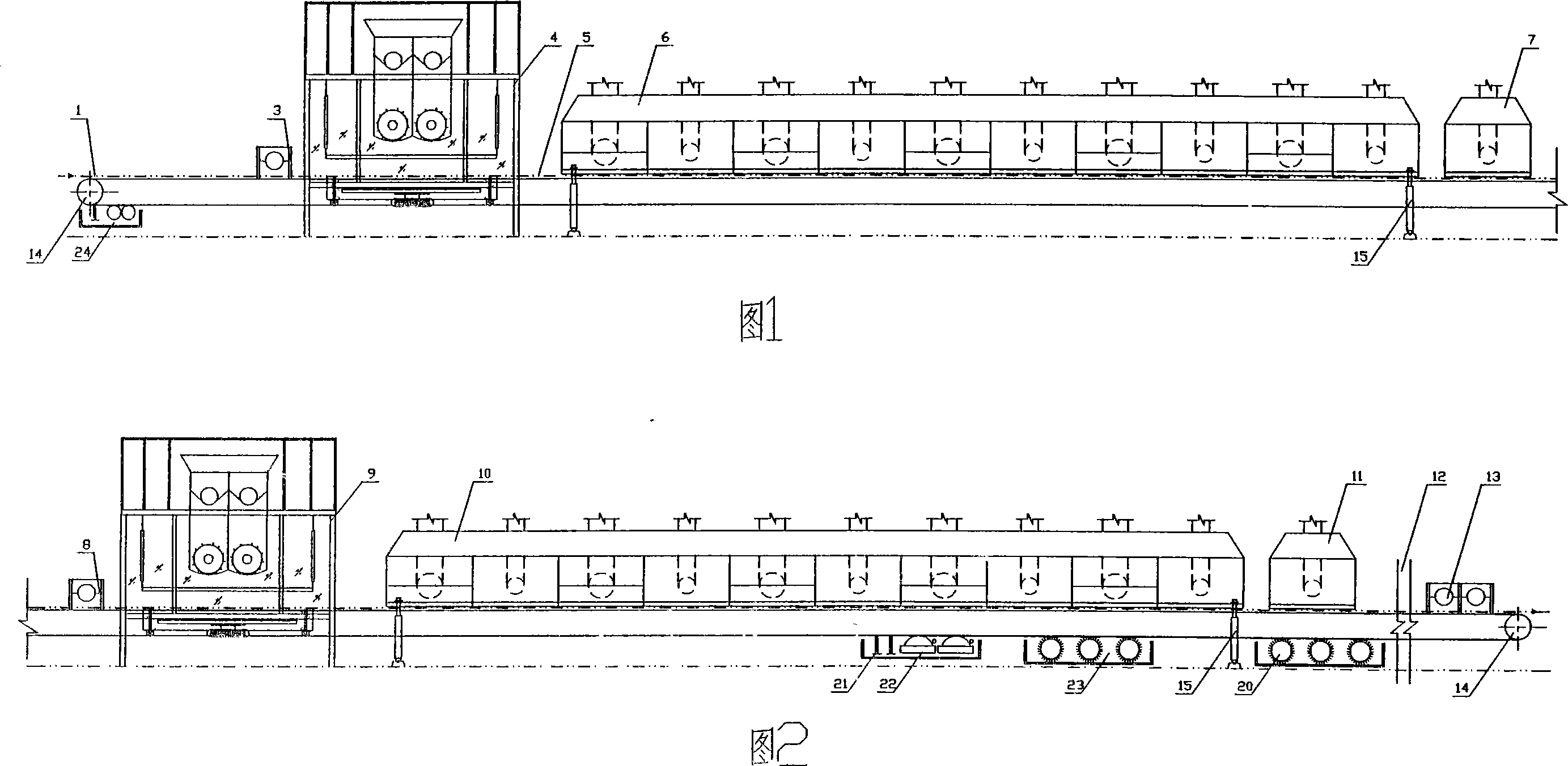

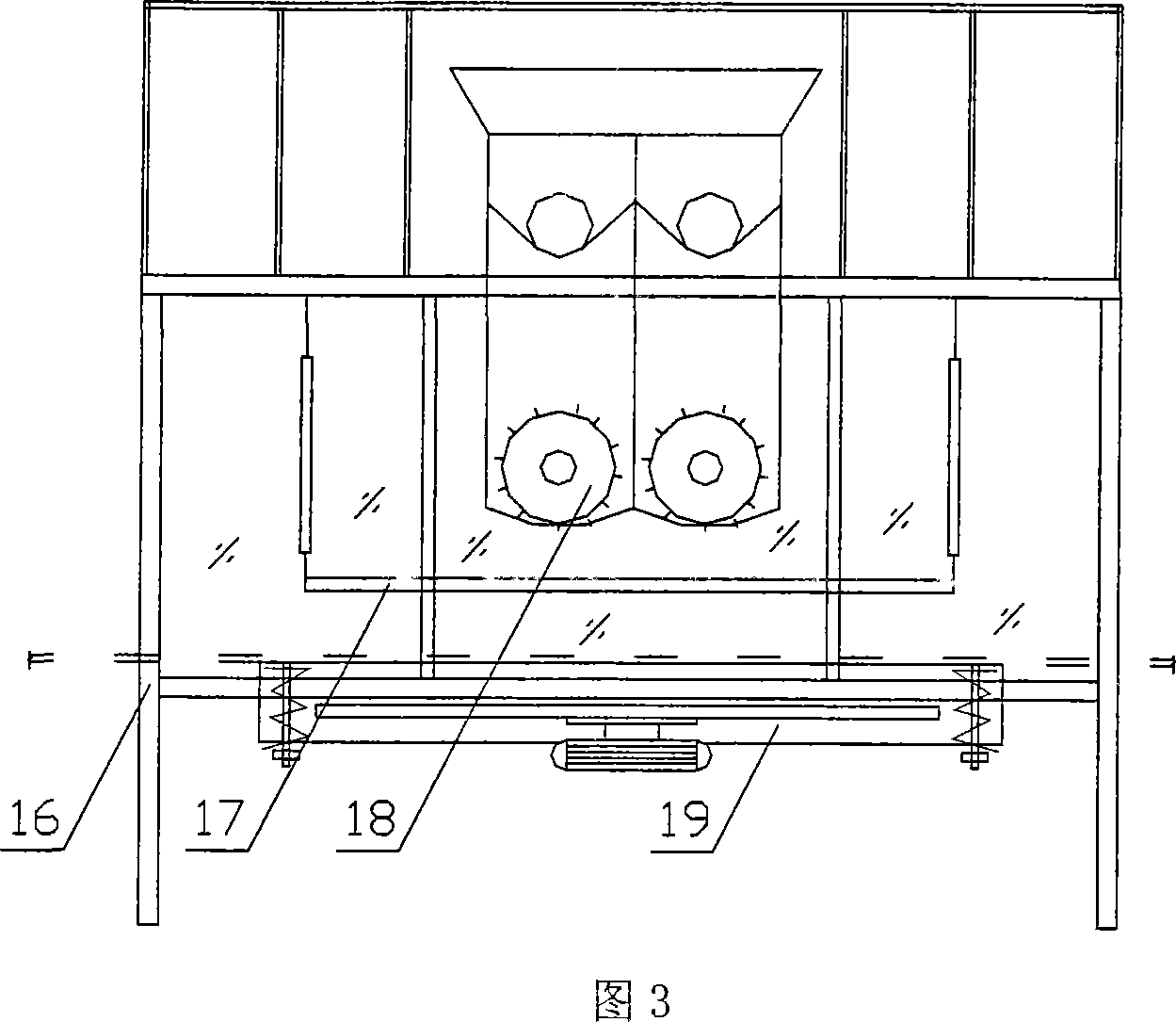

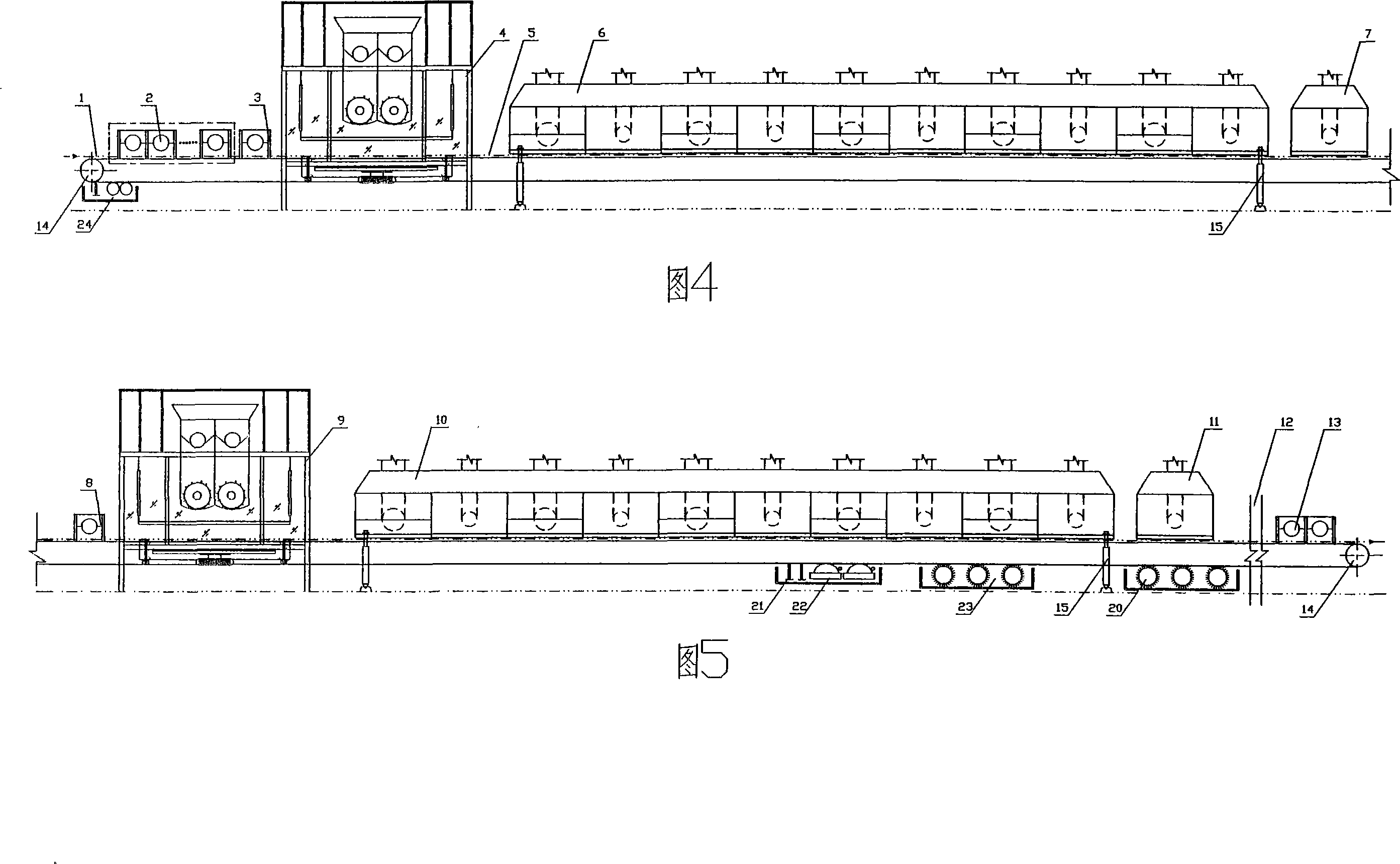

[0013] A kind of preparation method of grading gluing and color-separation flocking of the present invention is characterized in that it is carried out according to the following steps: (1) according to the color blocks and positions of several different colors of the color-separation flocking flower cloth product in the position to be printed Correspondingly divide several times of gluing and flocking areas on the base fabric; (2) After each alignment gluing and color separation flocking, drying and air-cooling treatment are carried out subsequently, as a step to complete a color flocking Production and preparation unit; (3) According to the number of color blocks of different colors in the horizontal direction of the transmission mechanism of the base fabric to be printed, several sets of alignment gluing, color separation flocking, drying and air cooling equipment are correspondingly equipped, Wherein the production and preparation unit of the last color color block is only ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com