Patents

Literature

47results about How to "Meet the needs of domestic and foreign markets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

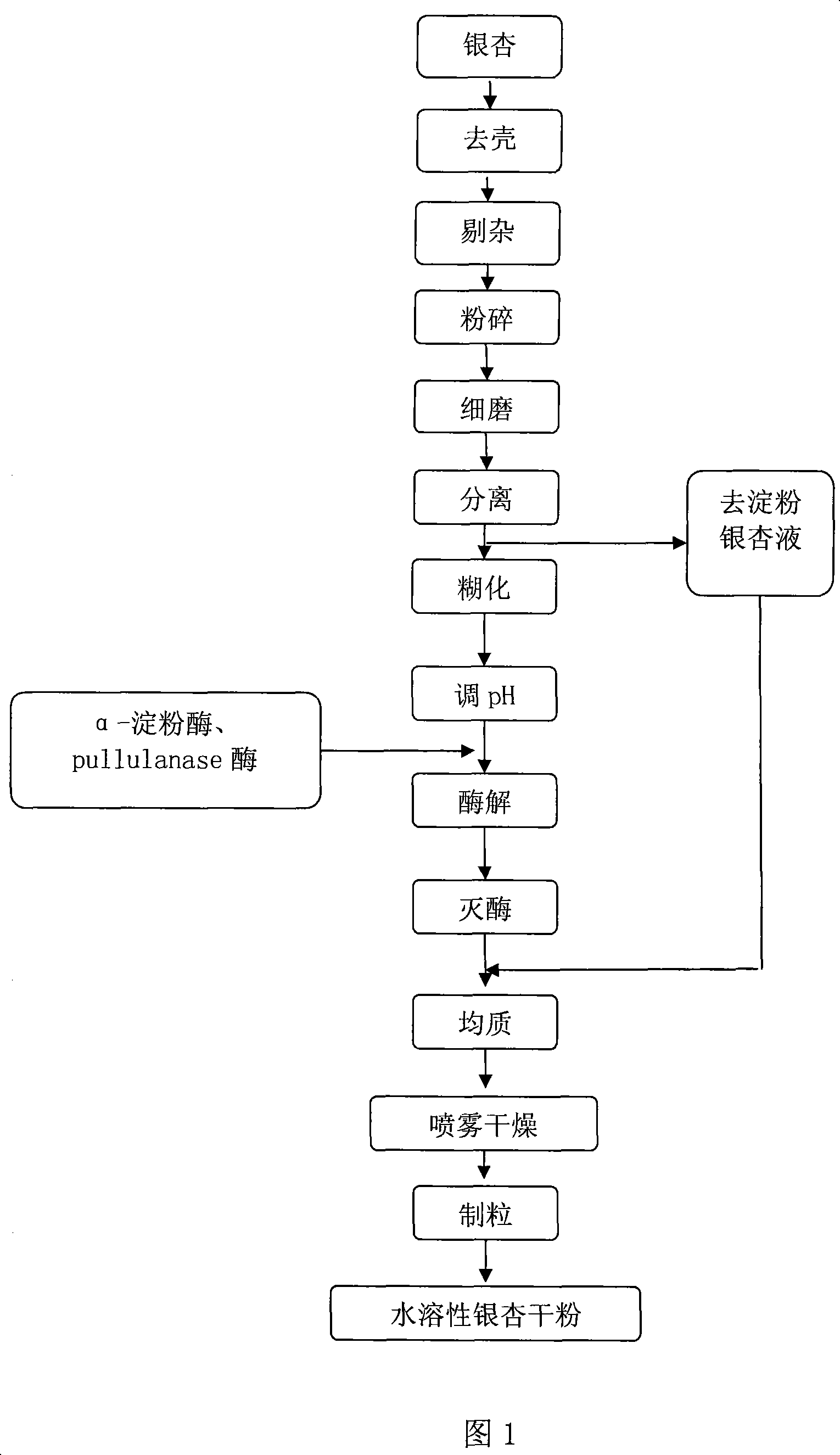

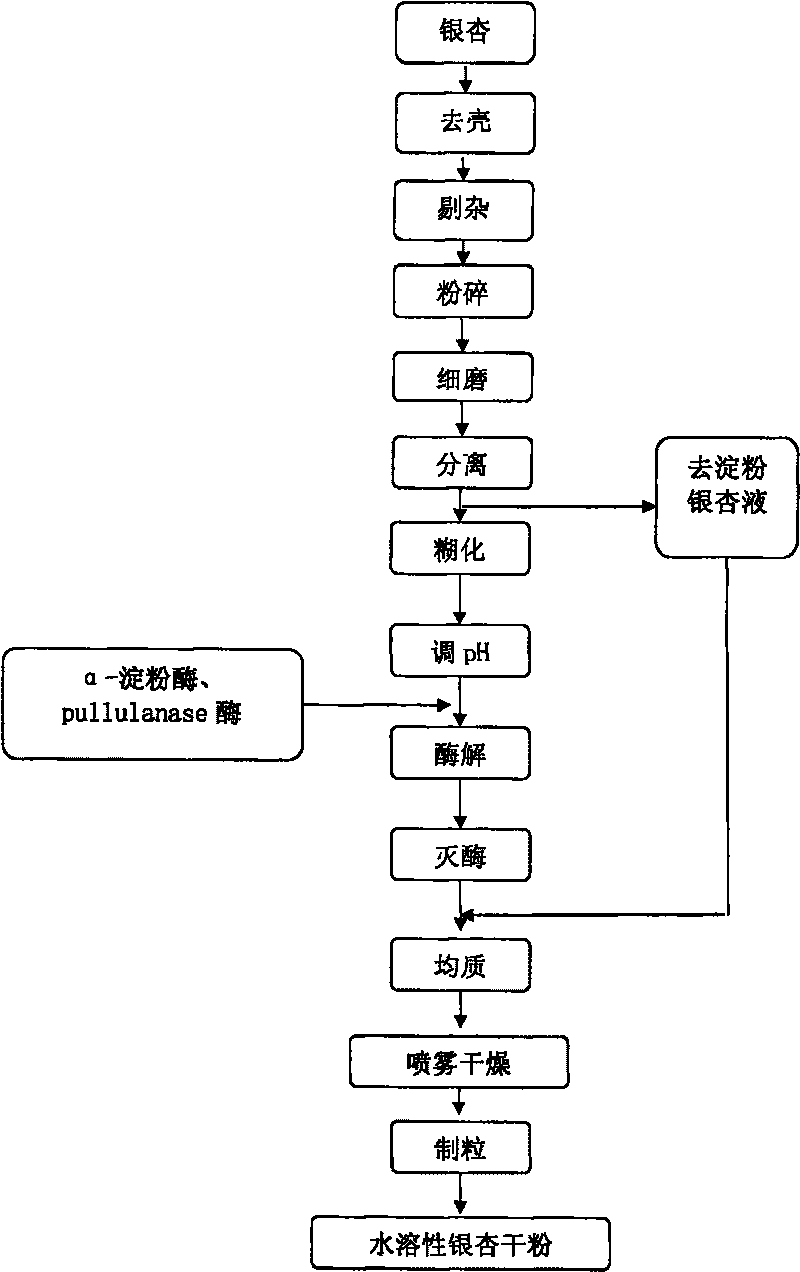

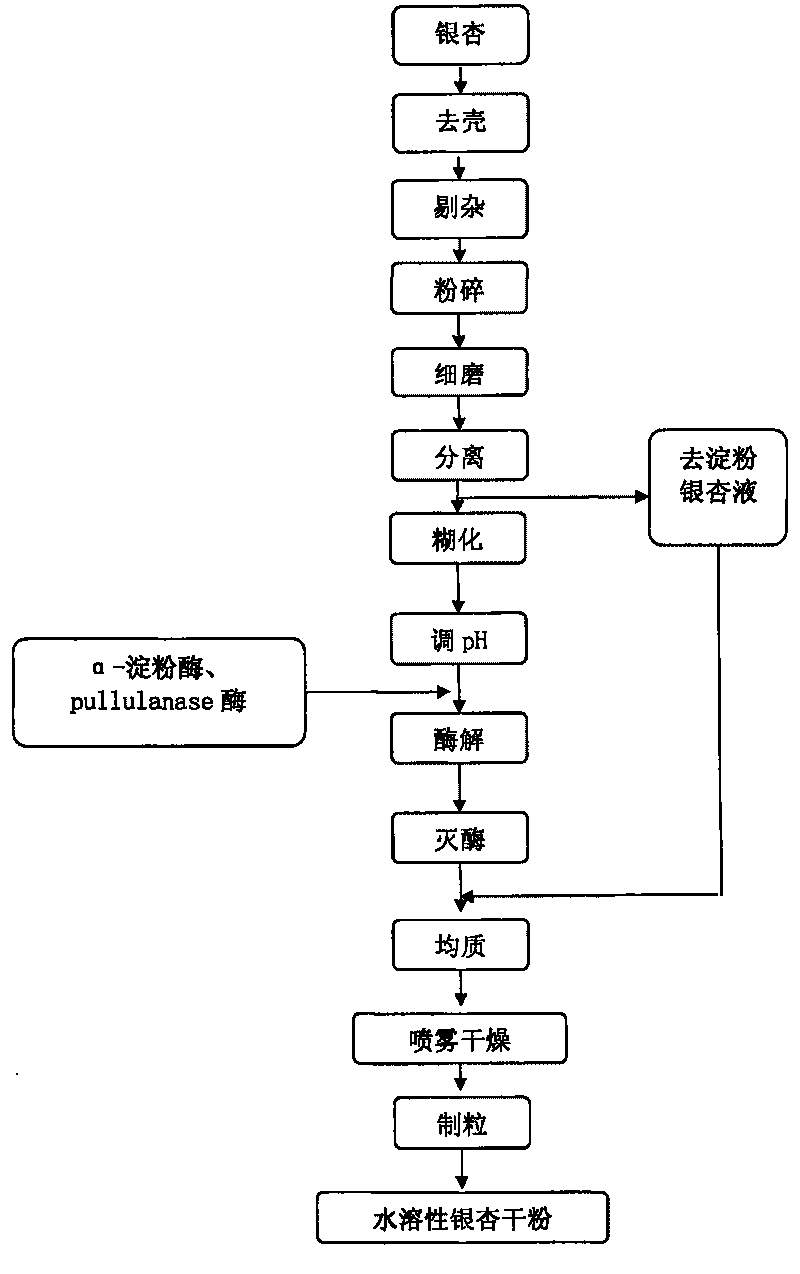

A method for preparing water-solubility ginkgo powder

InactiveCN101156703AHistoricalSufficiently retain the nutritional ingredients of medicinal dietMilk preparationFood preparationCyanide compoundSolubility

The invention relates to a production method of a water soluble gingko powder, and belongs to the gingko processing technical field. The invention takes fresh gingko as the raw material, the gingko seeds are crushed with water after being shelled, the gingko starch and the destarch gingko solution are respectively obtained through precipitation separation, the gingko starch obtains the gingko starch hydrolyzed solution through the enzymolysis of amylase and pullulanase together, and the gingko starch hydrolyzed solution and the destarch gingko solution adopt homogenization treatment and spray drying after being mixed, so as to produce a water soluble gingko powder of the residual of non-cyanide. The water soluble gingko powder holds the gingko fragrance and the nutrition component. And thereby the invention has vital significance to the comprehensive utilization of the gingko resources.

Owner:JIANGNAN UNIV

Preparation method for extracting agar under assistance of compound enzyme method

InactiveCN104911229AReduce the amount of alkali usedReduce the amount of acid usedFermentationEnvironmental chemistryEnzyme method

The invention discloses a preparation method for extracting agar under the assistance of a compound enzyme method. The preparation method comprises the steps of enzyme treatment, alkali treatment, alkali washing, acidification, acid washing, bleaching, decolorizer washing, agar extraction and fine filtration. The preparation method is environmentally friendly. Compared with a traditional method, by the adoption of the compound enzyme method, the concentration of alkali is reduced, the use amount of acid is reduced, and thus discharge of sewage is reduced; meanwhile, by the adoption of the compound enzyme method, the agar extracting rate is increased, the transparency, the viscosity and the strength of agar are improved, and thus the preparation method has broad application prospects.

Owner:JIMEI UNIV

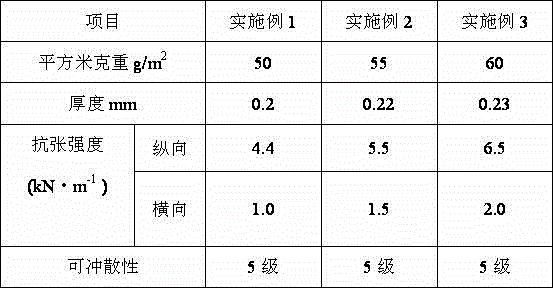

Raw paper for dispersed wet tissues and production method for raw paper

ActiveCN104452433AImprove wet strengthImprove wet wiping effectSynthetic cellulose/non-cellulose material pulp/paperFiberPapermaking

The invention relates to a production method for a nonwoven material, in particular to raw paper for dispersed wet tissues and a production method for the raw paper. The raw paper for the dispersed wet tissues is a nonwoven material obtained by sequentially executing a papermaking procedure, a spunlace entanglement procedure and a dehydration drying procedure on papermaking pulp consisting of 25 to 28 weight percent of polylactic acid fibers, 40 to 42 weight percent of coconut coal fibers and the balance of wood pulp fibers, and does not contain any additional bonding agent and wet strength agent. According to the raw paper for the dispersed wet tissues and the production method, a gap in a production technology for the raw paper for the dispersed wet tissues in China is supplied, foreign and domestic market requirements are met, and a conventional raw paper production process is simplified; papermaking is combined with spunlace, so that the production cost is lowered, and the wet strength, wet wiping effects and hydrolytic property of the raw paper for the dispersed wet tissues are importantly improved; an obtained product is high in dispersibility and biodegradability.

Owner:江门仁科绿洲纸业有限公司

Method for preparing mulberry brandy

ActiveCN102344868ARich varietyImprove product gradeAlcoholic beverage preparationDistillationStorage tank

The invention discloses a method for preparing mulberry brandy, which comprises the following steps of: inspecting, accepting, selecting, pulverizing and pulping the raw material, sterilizing the mulberry pulp at the temperature 110-115 DEG C for 3-6 s, fermenting the mulberry pulp, adjusting the temperature of the mulberry pulp to 18-25 DEG C, adding active dry yeast, and starting temperature controlled fermentation, wherein the mass ratio of the active dry yeast to the mulberry pulp is 1-1.2:10000, the fermentation time is 7-10 days, and the fermentation temperature is 18-25 DEG C; and completing fermentation when the content of residual sugar is less than or equal to 5.0 g / L, transferring the fermentation liquor into a storage tank, waiting for distillation, distilling the fermentationliquor in two steps of rough distillation and fine distillation, storing, brewing, blending and adjusting raw brandy, and storing, brewing and filtering semi-finished brandy to obtain the mulberry brandy. By using the preparation method, the raw material of mulberries can be fully utilized, the mulberry brandy has the advantages of abundant nutrient components and high product added value, rancidity is not easy to occur, and the disposal of pollutants can be effectively lowered so as to protect environmental sanitation.

Owner:ZHEJIANG PHARMA COLLEGE

Method for breeding scorpions

InactiveCN102812926ALong-lasting hypotensive effectHigh nutritional valueAnimal husbandryLitterMesobuthus martensii

Disclosed is a method for breeding scorpions. Domesticated buthus martensii karsches serve as female parents and wild eastern Asian king scorpions serve as male parents to be hybridized, and litters reproduced by pregnant scorpions are first-generation eastern Asian king scorpions. The first-generation eastern Asian king scorpions serve as female parents, the wild eastern Asian king scorpions serve as male parents to be hybridized, and litters reproduced by pregnant scorpions are second-generation eastern Asian king scorpions. The second-generation eastern Asian king scorpions serve as female parents, the wild eastern Asian king scorpions serve as male parents to be hybridized, and litters reproduced by pregnant scorpions are third-generation eastern Asian king scorpions. The wild eastern Asian king scorpions serving as male parents or female parents before hybridization can be selected, and individuals which are strong and yellow in gourd, yellowish and bright in tails, bulging and round in forelimb pincers, quick in action and sexually mature are selected. The method for breeding scorpions has the advantages of little investment, rapid effect taking, small labor intensity and no pollution. Both wild resources are protected, and requirements of domestic and foreign markets can be met.

Owner:邱民民

Colorful glaze magnesium-intensified ceramic

The invention discloses a reinforced ceramic of color glazed magnesium, which is characterized by the following: adopting silica as base; covering a layer of glazed color on the surface of magnesium ceramic with lead stripping quantity not more than 0.16mg / L and cadmium stripping quantity not more than 0.001mg / L; improving mechanic strength and glaze hardness.

Owner:蒋则全

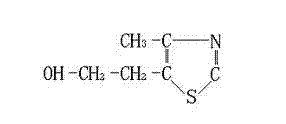

Synthesis method for 4-methyl-5-(2-ethoxyl)-thiazole

ActiveCN102584740AHigh yieldMeet market quality requirementsOrganic chemistrySynthesis methodsDistillation

The invention provides a preparation method for 4-methyl-5-(2-ethoxyl)-thiazole. The 4-methyl-5-(2-ethoxyl)-thiazole is synthesized from 2-acetylbutyrolactone serving as a raw material through amination, chloration, condensation and oxidative reaction. The preparation method comprises the following steps of: introducing chlorine into 2-acetylbutyrolactone and hydrolyzing to obtain 3-acetyl chloride propyl alcohol; introducing ammonia gas into carbon bisulfide to obtain ammonium salt; oxidizing a condensation product of 3-acetyl chloride propyl alcohol and the ammonium salt with hydrogen peroxide or oxygen to obtain a product; extracting with dichloromethane; removing the dichloromethane; then performing reduced pressure distillation; and collecting fraction at 120-127 DEG C under the pressure of 395-400 Pa. The synthesis method has the advantages of readily available raw material, low production cost, simple process, mild reaction conditions and yield of reaching up to 82 percent.

Owner:WUTONG AROMA CHEM CO LTD

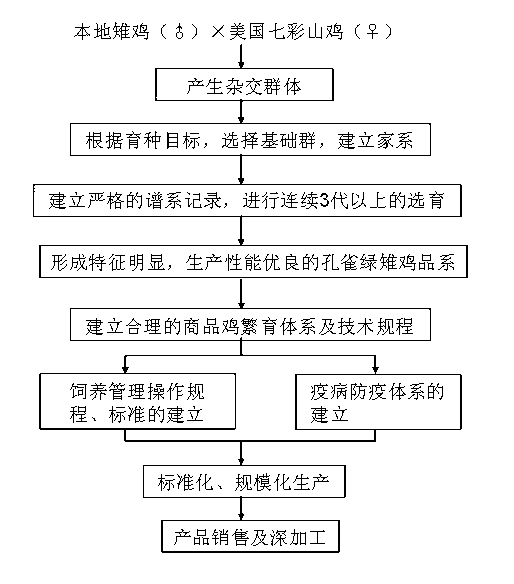

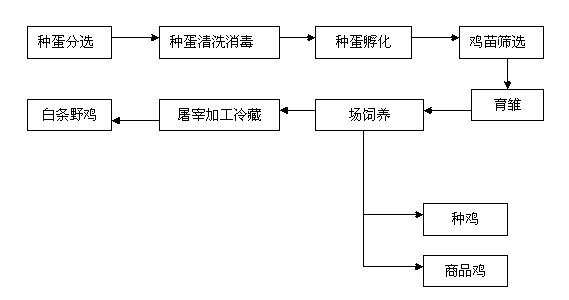

Novel peacock green pheasant breeding method

InactiveCN102696552AStrong individualStrong disease resistanceAnimal husbandryAnimal scienceGreen peafowl

The invention relates to a novel peacock green pheasant breeding method. The novel peacock green pheasant breeding method comprises the following steps: selecting a local pheasant as male parent and an American pheasant as a female parent for natural mating; hatching laid eggs to obtain a second-generation hybrid population; selecting cocks and hens with a relatively good plumage color from the second-generation hybrid population, as a base population; establishing a family of more than 30 chickens; in each family, naturally mating a second-generation hybrid cock with 5-10 second-generation hybrid hens; hatching laid eggs to obtain a third-generation hybrid population; performing cross breeding for more than 2 generations continuously; and eventually obtaining a new variety with a black hemp female body and a male parent with the similarity of the plumage color to the green peacock of more than 90%, wherein in the breeding process of each step, a pedigree record is establigreenhouse to avoid mutual mixture of different pedigrees. In bred green peacock pheasants, male bodies have highly consistent shapes and a green peacock plumage color, and the female bodies have a black hemp plumage color; the body weight is about 1000 g; the disease resistance is strong; the feed conversion and the egg production rate are high; and the bred green peacock pheasants are tender and delicious in meat and high in nutritional value.

Owner:唐正红

Monocrystal silicon wafer polishing process capable of obtaining high polishing rate

ActiveCN102962756ASpeed up thermal motionAccelerated corrosionPolishing machinesEngineeringForeign market

The invention relates to a monocrystal silicon wafer polishing process capable of obtaining a high polishing rate. In a coarse polishing process, an American Dupont SR330 coarse polishing solution is adopted, and diluted by pure water according to the ratio of 1:20 to 1:40; the flow is 23.5-24.5 L / min; a Rohm and Haas SUBA600 polishing pad is adopted; and the coarse polishing process comprises the following three steps: 1, using a coarse polishing solution to polish for 10 s, the rotating speed of a big disk being 23-27 rpm, the rotating speed of a central guide wheel being 48-52 rpm, and the pressure being 47-53 kPa; 2, using a coarse polishing solution to polish for 7-13 min, the rotating speed of the big disk being 38-42 rpm, the rotating speed of the central guide wheel being 78-82 rpm, and the pressure being 100-200 kPa; and 3, using pure water to polish for 40 s, the rotating speed of the big disk being 23+ / -27 rpm, the rotating speed of the central guide wheel being 48-52 rpm, and the pressure being 47-53 kPa. The polished section processed by the process has the removal rate up to 1.83-2.09 micron / min, which is far higher than the average level of 1 micron / min in the industry, and meanwhile, and has the pass percent up to more than 90% stably. The improvement of the productivity of the polished section can reduce the fixed cost, thereby meeting the requirements of domestic and foreign markets.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

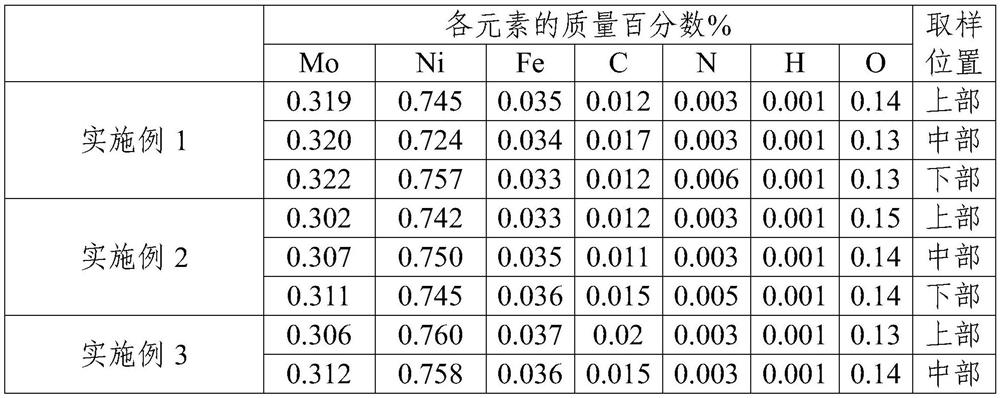

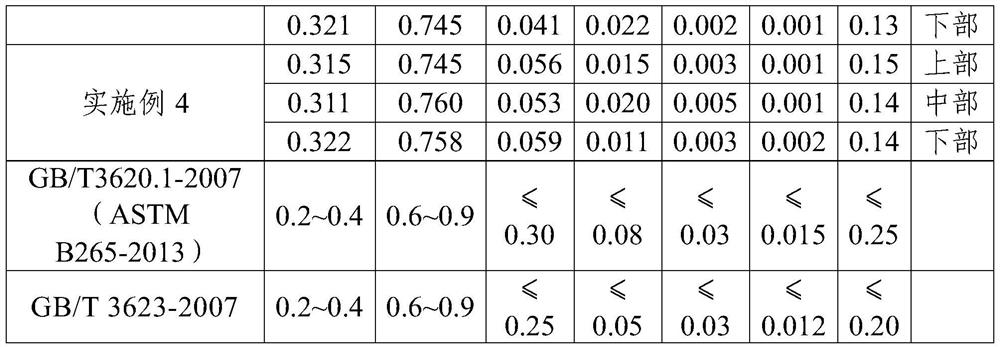

Method for preparing TA10 defective material into cast ingot by using duplex process

The invention discloses a method for preparing a TA10 defective material into a cast ingot by using a duplex process. The method comprises the following steps that 1, the TA10 defective material is distributed in an electron beam cold bed furnace, then electron beam cold bed smelting is carried out to obtain an electron beam cold bed smelted cast ingot; and 2, vacuum consumable electrode arc melting is carried out on the electron beam cold bed smelted cast ingot twice to obtain the TA10 cast ingot. According to the method, the TA10 defective material is prepared into the TA10 cast ingot through the duplex process of electron beam cold bed smelting and vacuum consumable electrode electric arc smelting, through the material distribution and technological parameter control of the duplex process, it is guaranteed that element distribution in the TA10 cast ingot is uniform, the utilization rate of the TA10 defective material is increased, the production cost of the TA10 cast ingot is reduced, the production efficiency is improved, the TA10 cast ingot meets the national standard requirement, and the phenomena of cracking, surface peeling and the like do not exist in the subsequent machining process.

Owner:WESTERN TITANIUM TECH

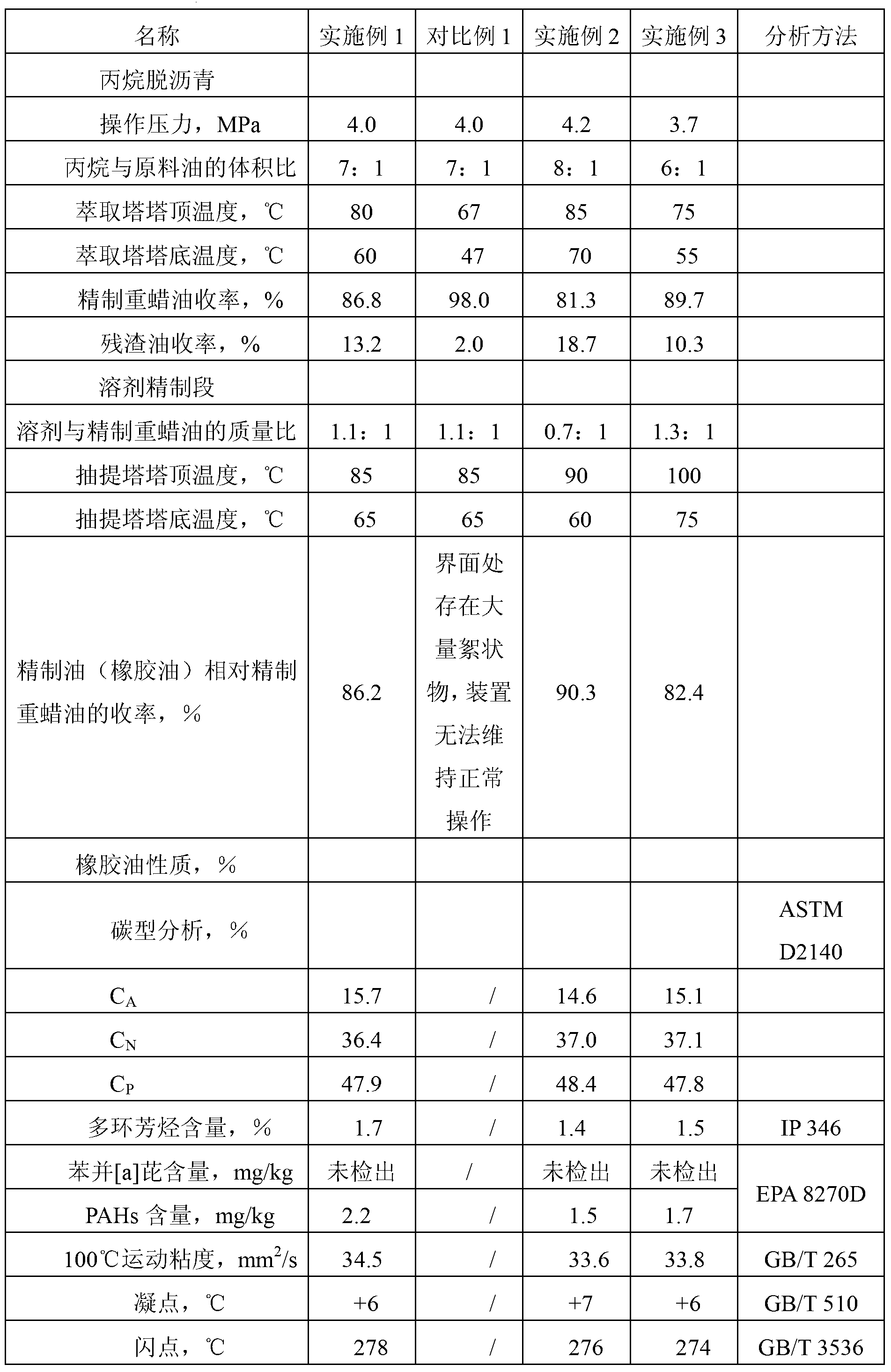

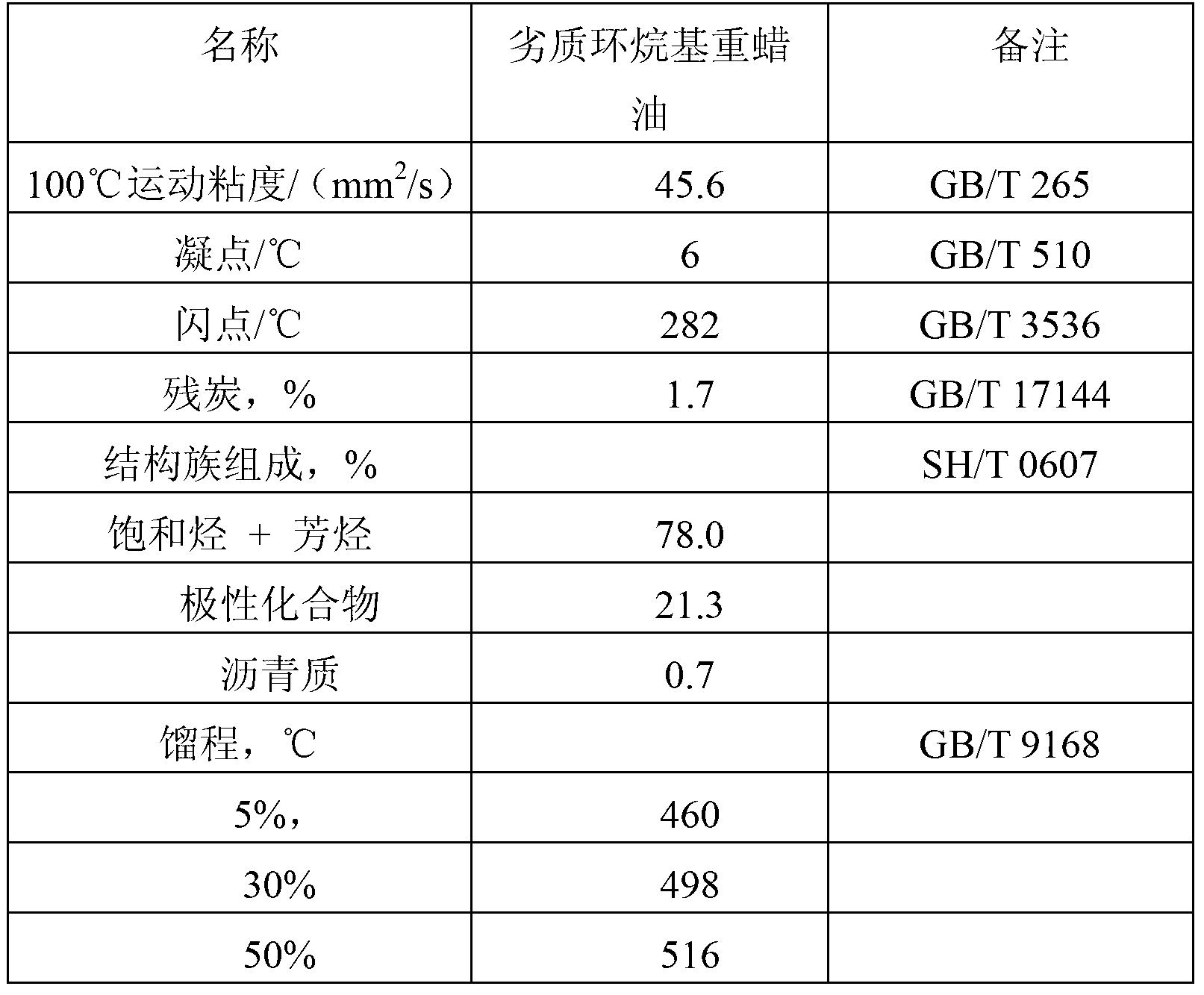

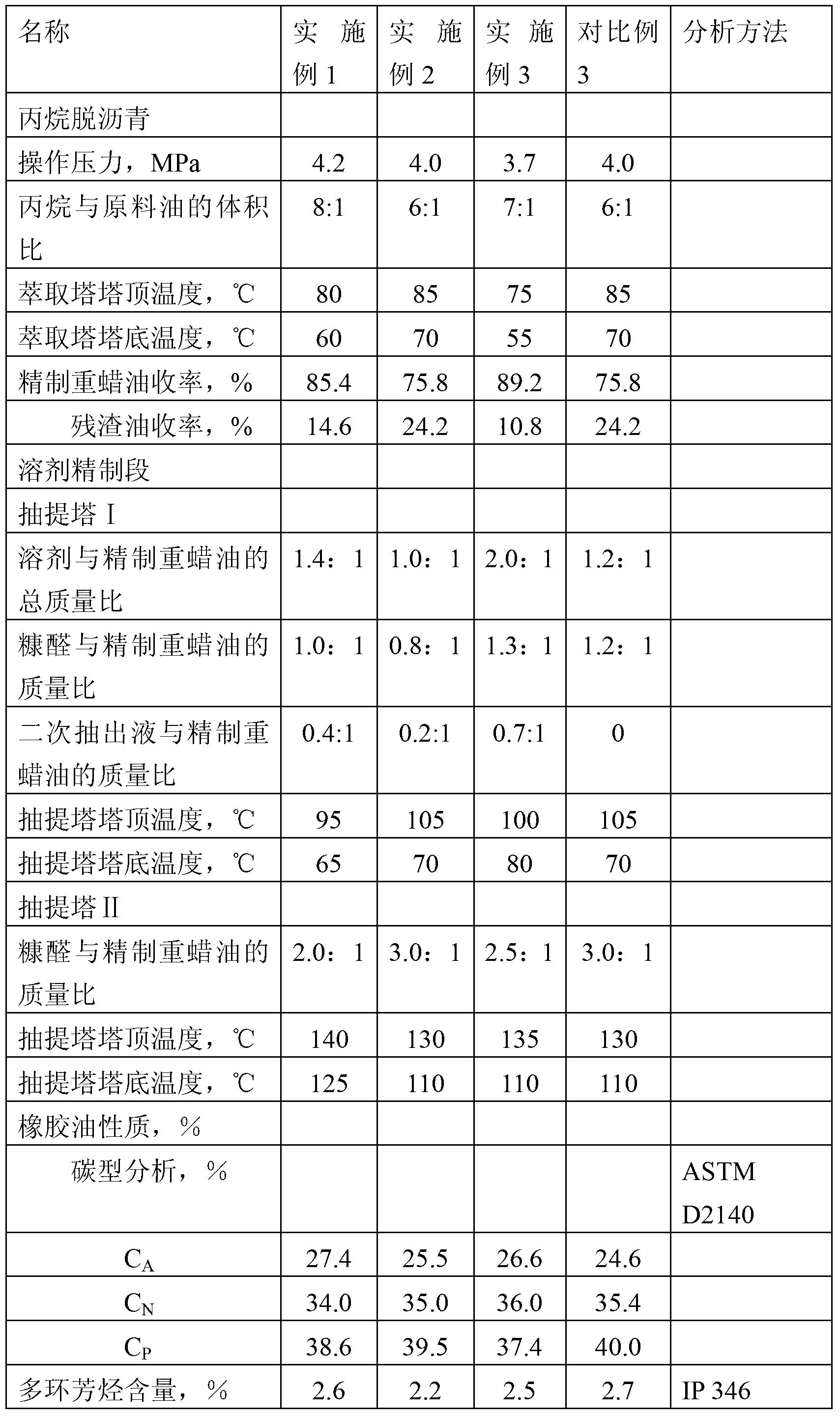

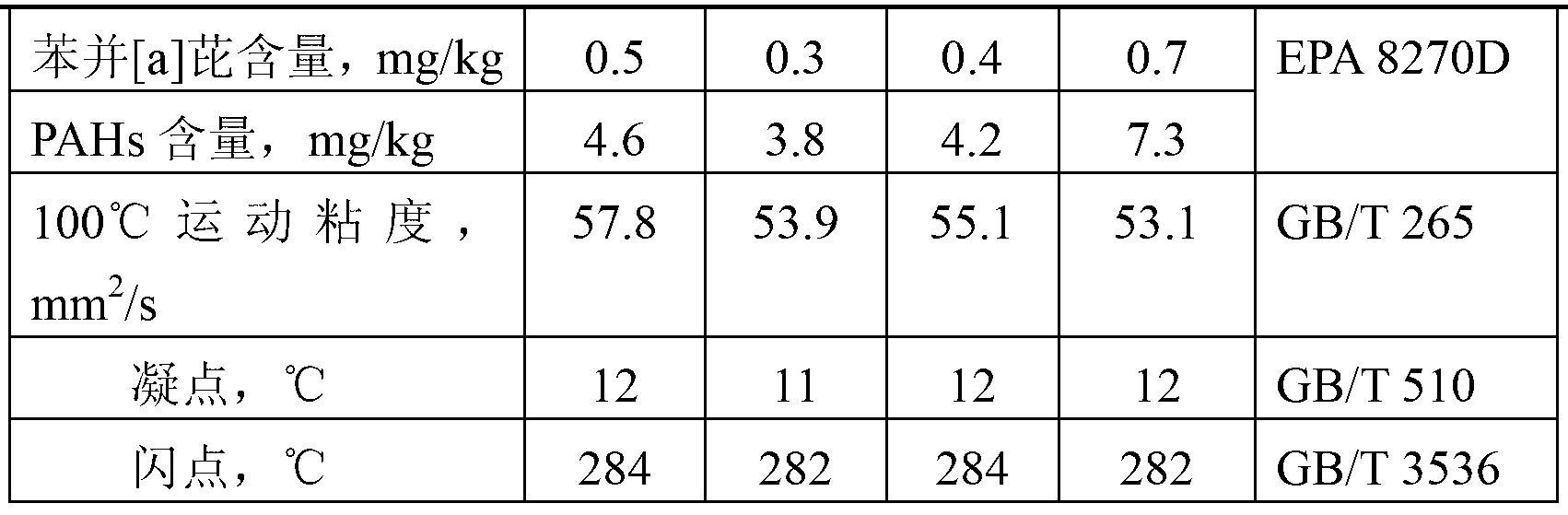

Method for producing environmentally-friendly rubber oil through using inferior cycloalkyl heavy wax oil, and environmentally-friendly rubber oil prepared therethrough

ActiveCN103320163AIncrease added valueBroaden sources of raw materialsTreatment with plural serial refining stagesWaxTower

The invention discloses an environmentally-friendly rubber oil and a preparation method thereof. The method comprises the following steps: 1, extracting inferior cycloalkyl heavy wax oil in a propane deasphalting extraction tower with propane to obtain a refined liquid at the top of the propane deasphalting extraction tower, and recovering a solvent to obtain refined heavy wax oil; and 2, carrying out solvent refinement of the refined heavy wax oil in an extraction tower to obtain an extract liquid at the bottom of the extraction tower and a refined liquid at the top of the extraction tower, recovering the solvent of the extract liquid to obtain extract oil, and recovering the solvent of the refined liquid to obtain the environmentally-friendly rubber oil. The method utilizing the inferior cycloalkyl heavy wax oil to prepare the environmentally-friendly rubber oil widens the raw material source of the environmentally-friendly rubber oil, satisfies the demands of the markets at home and abroad, and also greatly improves the added values of the inferior cycloalkyl heavy wax oil. The method has the advantages of small solvent ratio in the solvent refining process, low energy consumption and solvent consumption, and high target product yield.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Preparation process of ME20M magnesium alloy flat ingot

The invention discloses a preparation process of a ME20M magnesium alloy flat ingot. The preparation process comprises the flow steps of melting by a melting furnace-primary analysis and test-refiningby a refining furnace-secondary analysis and test-standing and semicontinuous casting; a crystallizer is reasonably designed; the temperature and the flowing speed of magnesium alloy liquid guided inthe crystallizer are accurately mastered; such phenomenon as easy fire leakage in the casting process of the ME20M magnesium alloy flat ingot and influence on the product quality by weak fluidity ofthe magnesium alloy liquid in the crystallizer and easy generation of large cold shut is overcome; fifth solvent can prevent oxide inclusions in the smelting process of a ME20M magnesium alloy; the utilization rate of metal cerium is increased; a protective film isolated from air can be formed on the surface of magnesium alloy liquid; and self preparation of a refining agent achieves the followingpurposes: (1) the effects of the fifth solvent are achieved; and (2) impurities in the magnesium alloy liquid are fully precipitated to guarantee that the cast magnesium alloy flat ingot has no defects of inclusions and air holes.

Owner:洛阳晟雅镁合金科技有限公司

Yam freezing technology

InactiveCN102047945AIncrease incomeWith tasteFruits/vegetable preservation by freezing/coolingFlavorQuick Freeze

The invention relates to a vegetable freezing technology, in particular to a yam quick-freezing technology which belongs to the technical field of deep processing of farm and sideline products. The technology comprises measures of collecting raw materials, treating the raw materials, packaging and the like, pretreatment, low-temperature monomer quick freezing, low-temperature packaging and warehousing are sequentially carried out on yam, and a finished product is white with slight straw yellow, has peculiar taste and flavor, has no peculiar smell and can meet the market demands at home and abroad and simultaneously improve the income of peasants.

Owner:吴继明

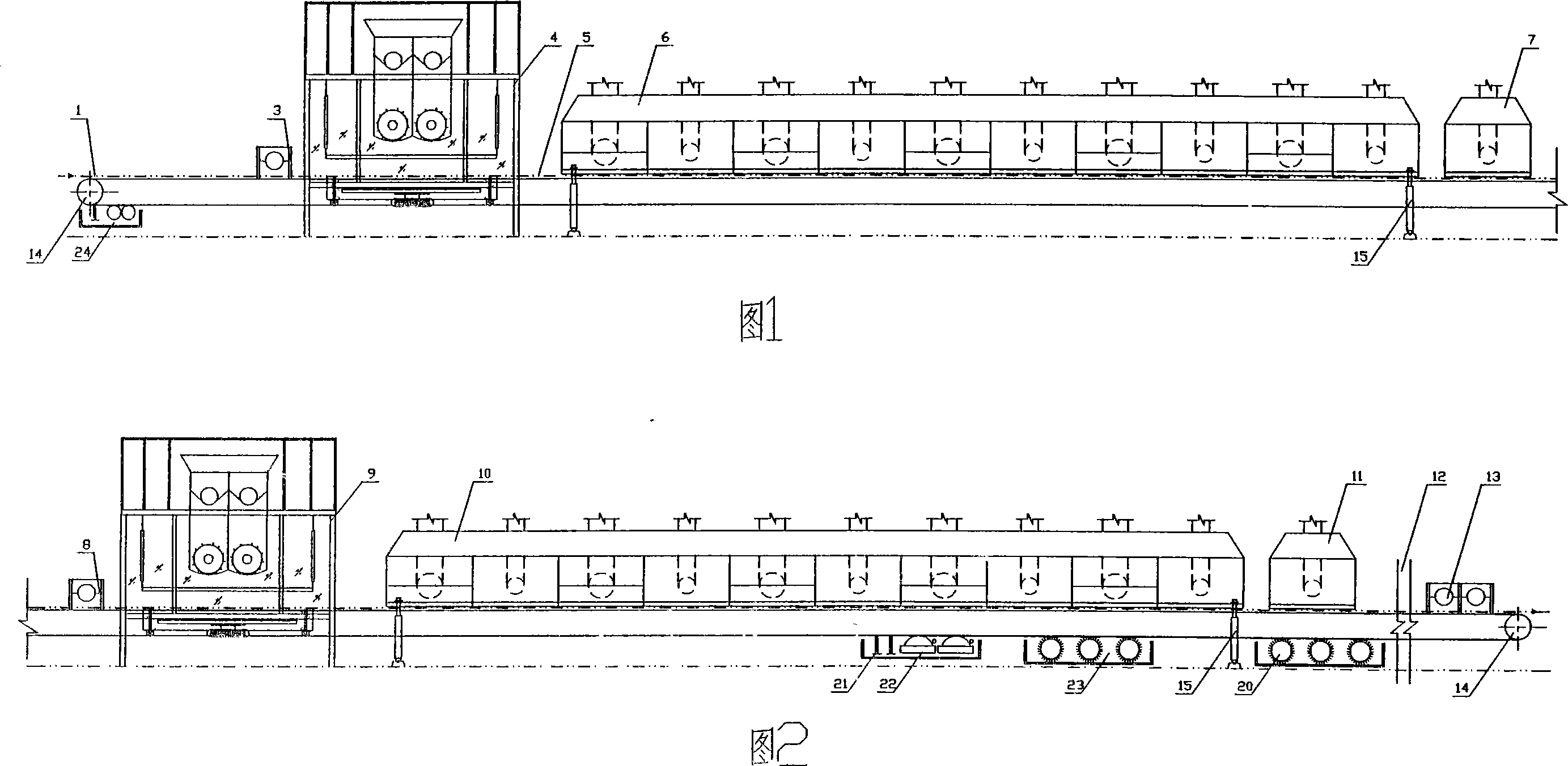

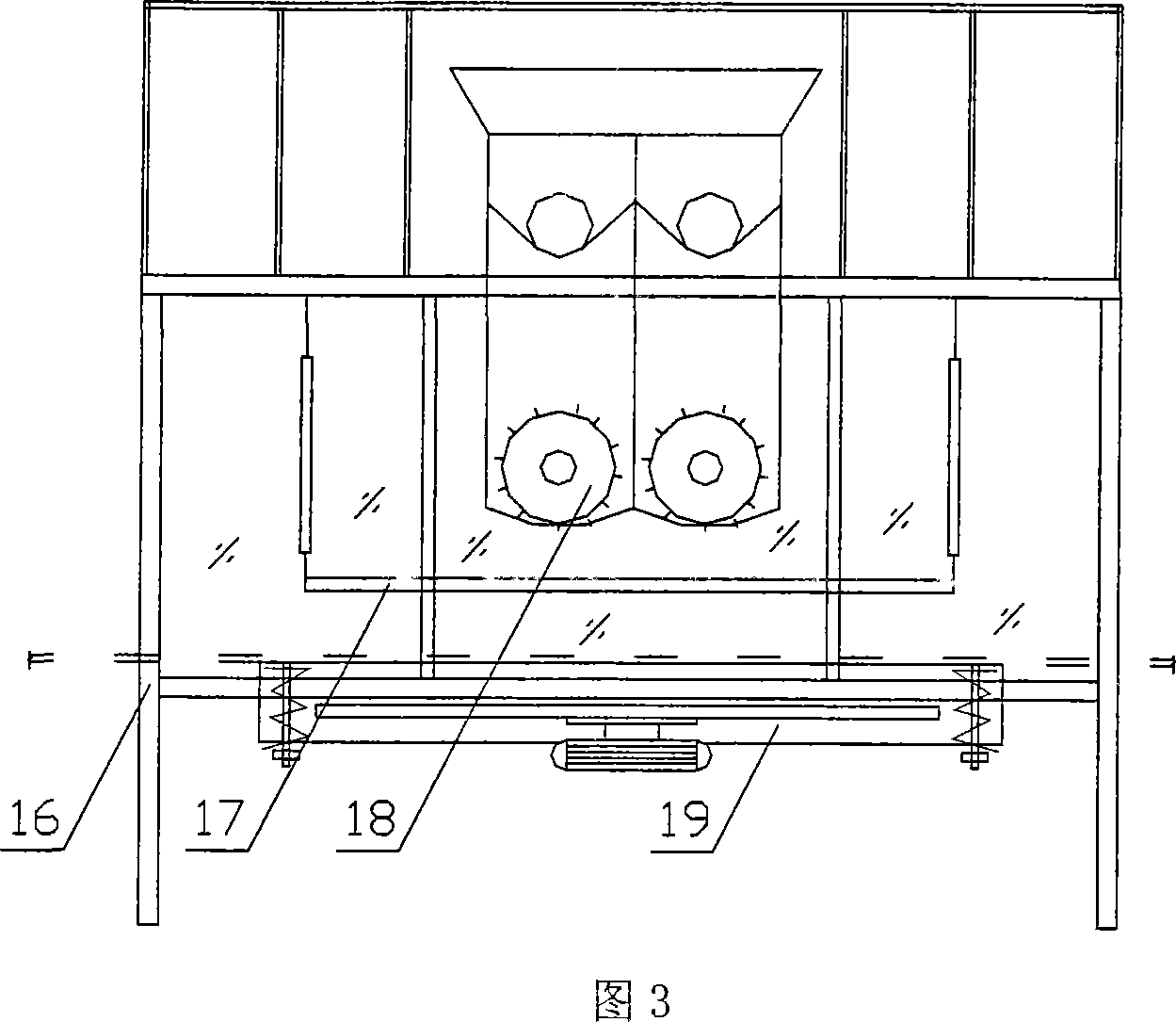

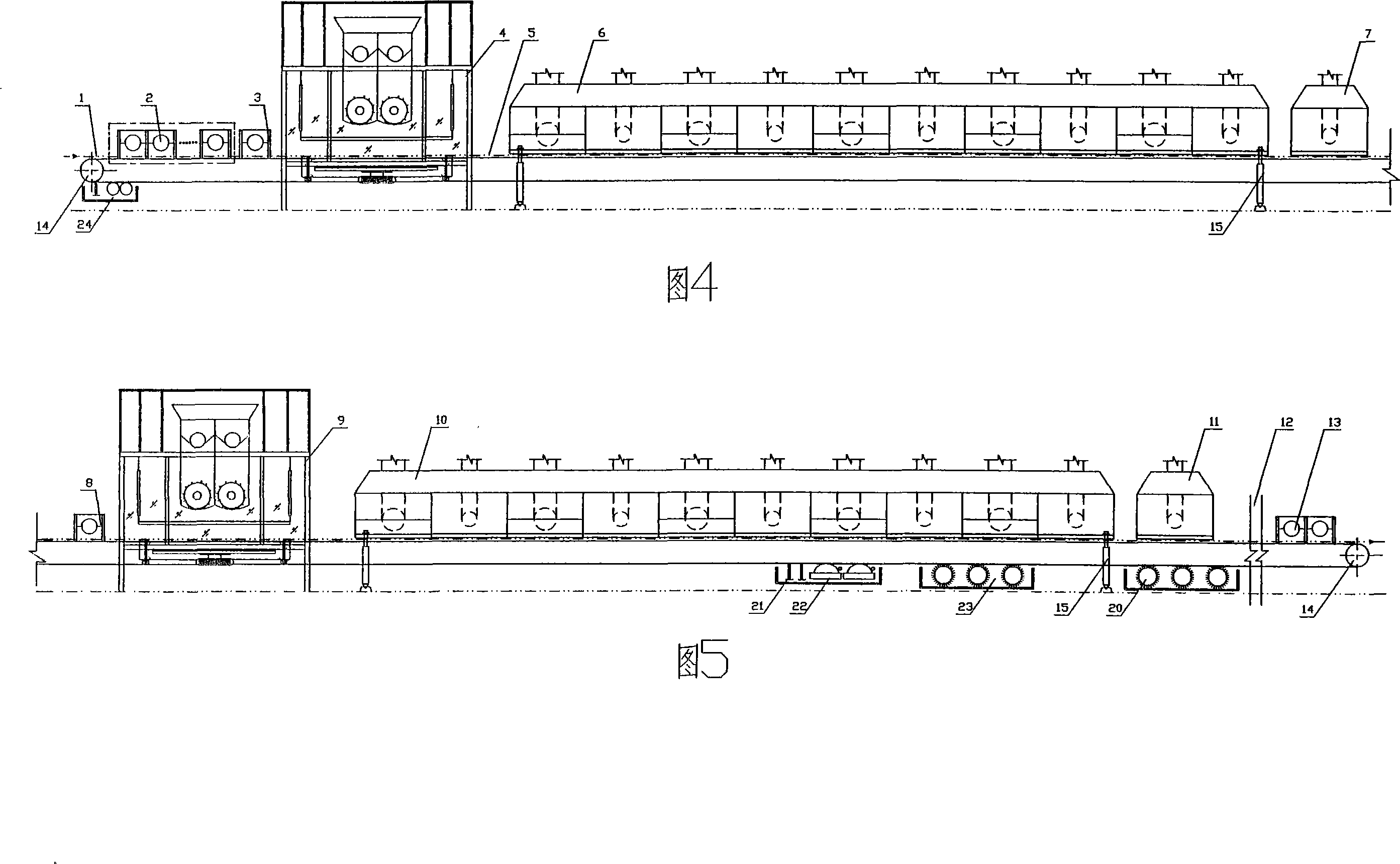

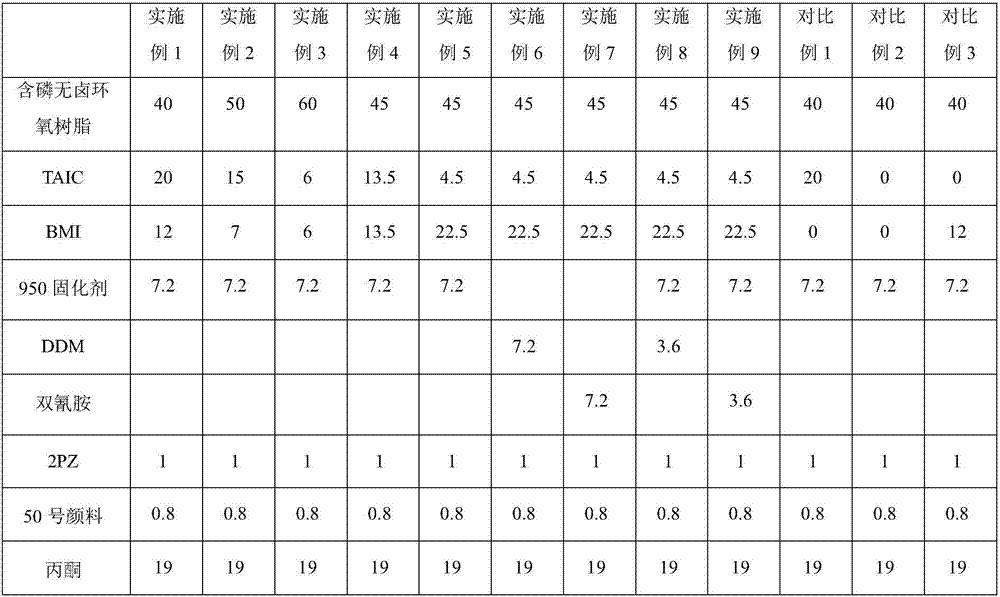

Method of preparing graded cementing and colour separation pile coating and special hardware thereof

InactiveCN101229542AClear boundariesAccurate flower positionFibre treatmentPretreated surfacesProduction lineFractionation

Owner:谢开兴

Heavy environmentally-friendly rubber oil and preparation method thereof

ActiveCN103320164ABroaden sources of raw materialsIncrease added valueTreatment with plural serial refining stagesWaxChemistry

The invention discloses a heavy environmentally-friendly rubber oil and a preparation method thereof. The method comprises the following steps: extracting inferior cycloalkyl heavy wax oil in a propane deasphalting extraction tower with propane obtain a refined liquid at the top of the propane deasphalting extraction tower, and recovering a solvent to obtain refined heavy wax oil; and 2, carrying out solvent refining of the refined heavy wax oil in an extracting tower I to obtain a primary refined liquid at the top of the extracting tower I and a primary extract liquid at the bottom of the extracting tower I, and recovering the solvent of the primary extract liquid to obtain primary extract oil; and 3, carrying out solvent refining of the primary refined liquid in an extracting tower II to obtain a secondary refined liquid at the top of the extracting tower II and a secondary extract liquid at the bottom of the extracting tower II, recovering the solvent of the secondary refined liquid to obtain secondary refined oil, and recovering the solvent of the secondary extract liquid to obtain the heavy environmentally-friendly rubber oil. The method utilizing the inferior cycloalkyl heavy wax oil to prepare the environmentally-friendly rubber oil widens the raw material resource of the environmentally-friendly rubber oil, satisfies the market demands at home and abroad, and also greatly improves the added values of the inferior cycloalkyl heavy wax oil.

Owner:CHINA NAT OFFSHORE OIL CORP +3

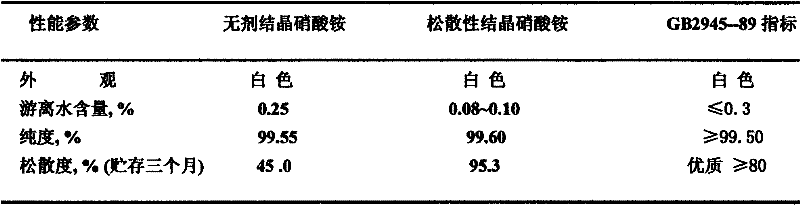

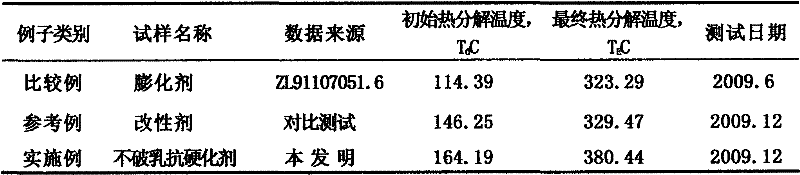

Anti-hardener for high-stability crystal ammonium nitrate without demulsification

InactiveCN102311296AChange the old concept that cannot be mixedStable shelf life performanceNon-explosive/non-thermic compositionsFertilizerNitro compound

The invention provides an anti-hardener for high-stability crystal ammonium nitrate without demulsification, is characterized in that the anti-hardener is composed of a crystal controlling agent, a stabilizing agent, a desiccator and an antiadherent, and aims to solve defects such as the incompatibility of a modifier for crystal ammonium nitrate with an emulsifier in an emulsion explosive or powdery emulsion explosive matrix during the actual usage of the modifier developed by predecessors. According to the invention, an unsymmetrical structural anionic surfactant anionic surfactant sulfonateis used as the stabilizing agent to prevent the demulsification of the emulsification matrix during the process of the emulsion explosive or powdery emulsion explosive production and ensure the stabilization of the emulsion explosive or powdery emulsion explosive production technology and product storage period performance. The invention can also be applied in the preparation of loose expanded ammonium nitrate as well as a loose high-nitrogen nitro compound fertilizer. According to the invention, the additive concentration ranges from 0.12% to 0.15%.

Owner:太原海力丰科技发展有限公司

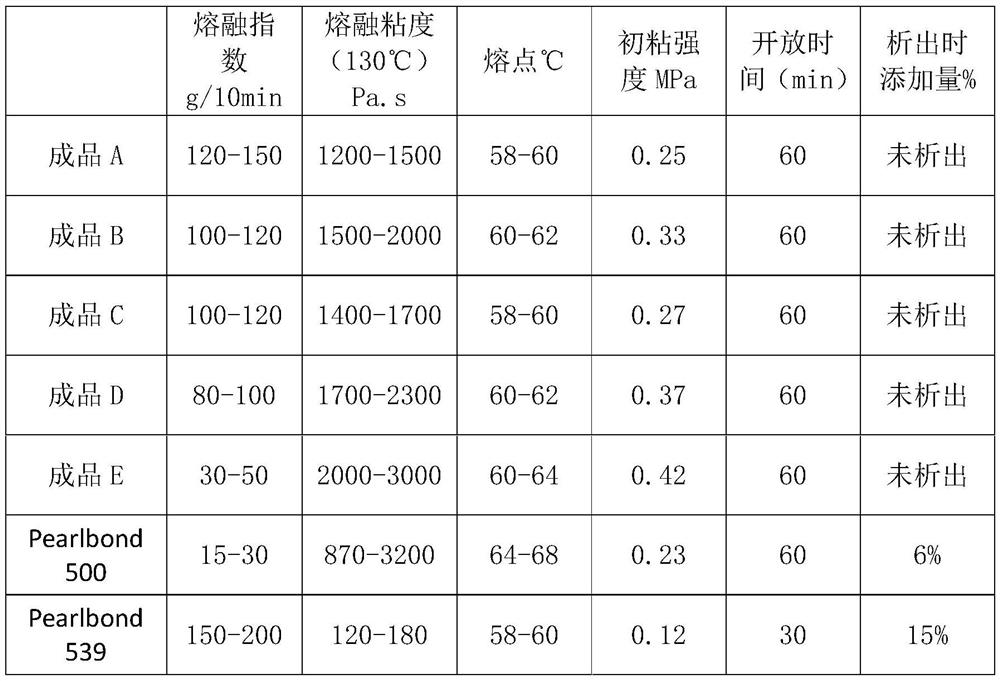

Preparation method of thermoplastic polyurethane elastomer for reactive hot melt adhesive

ActiveCN112708101APromote meltingGood adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a preparation method of a thermoplastic polyurethane elastomer for a reactive hot melt adhesive. The preparation method comprises the following steps of: adding 50-80 parts of polyester polyol and 5-10 parts of dihydroxy-terminated polybutadiene into a reaction kettle, controlling the temperature to be 115-120 DEG C and the vacuum degree to be less than or equal to 0.095 MPa, and carrying out vacuum dehydration for 2-3 hours; after dehydration treatment, cooling the mixture obtained in the previous step to 78-82 DEG C, adding 10-40 parts of polyisocyanate, 0-0.5 parts of a catalyst, 0-1.0 part of an antioxidant and 0-1.0 part of an anti-yellowing agent into the reaction kettle, stirring at the speed of 80-150 r / min, uniformly mixing, and stirring at the temperature of 80-85 DEG C, the vacuum degree of less than or equal to 0.095 MPa and the speed of 80-150 r / min for reaction for 3 hours; obtaining a thermoplastic polyurethane elastomer for a reactive hot melt adhesive; and packaging and sealing the thermoplastic polyurethane elastomer for the reactive hot melt adhesive in the previous step under the protection of nitrogen to obtain a finished product. The thermoplastic polyurethane elastomer prepared by the invention can improve the initial adhesion strength of a reactive polyurethane hot melt adhesive, increase the melt viscosity and improve the cohesion, has excellent compatibility, and can meet the market requirements at home and abroad.

Owner:LIAONING FIXED STAR FINE CHEM

Preparation method of nano plugging agent for plugging oil-gas well

InactiveCN111087989AImprove the blocking effectImprove rock-carrying abilityDrilling compositionActive agentProcess engineering

The invention discloses a nano plugging agent for plugging an oil-gas well and a preparation method thereof. The nano plugging agent comprises the following components in parts by weight: 50-90 partsof water, 8-10 parts of sodium carbonate, 8-9 parts of a cementing material, 4-6 parts of a calcium chloride water solution, 11-15 parts of an emulsifier, 3-6 parts of a composite plugging agent, 2-5parts of a blender, 1-2 parts of methyl methacrylate, 1-2 parts of a surfactant and 2-3 parts of a pH regulator. The constant temperature is preferably 25 DEG C. The beneficial effects of the nano plugging agent are that: according to the preparation method of the nano plugging agent, the prepared base slurry interacts with various reagents, finally an emulsifier and a surfactant are added and mixed to obtain the nano plugging agent, the plugging capacity and the rock carrying capacity of the nano plugging agent are enhanced, and the nano plugging agent has the characteristics of safety, environmental protection and hydrocarbon reservoir protection, can be used for multiple times, has no side effect, and can well meet the market requirements at home and abroad.

Owner:南京化学工业园环保产业协同创新有限公司

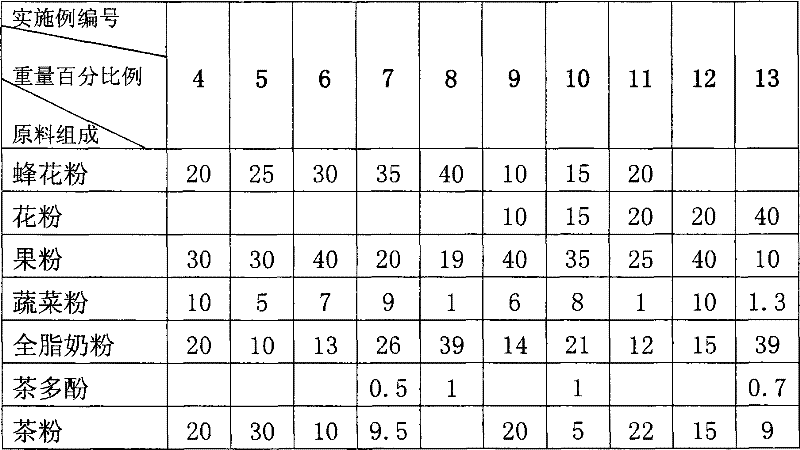

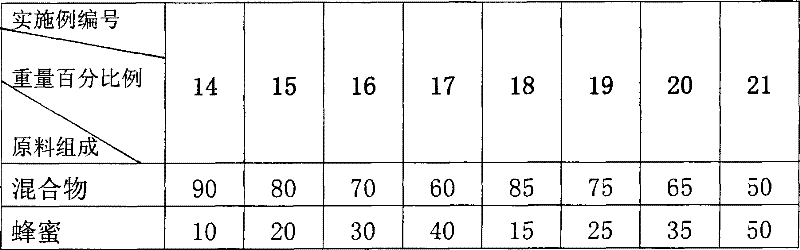

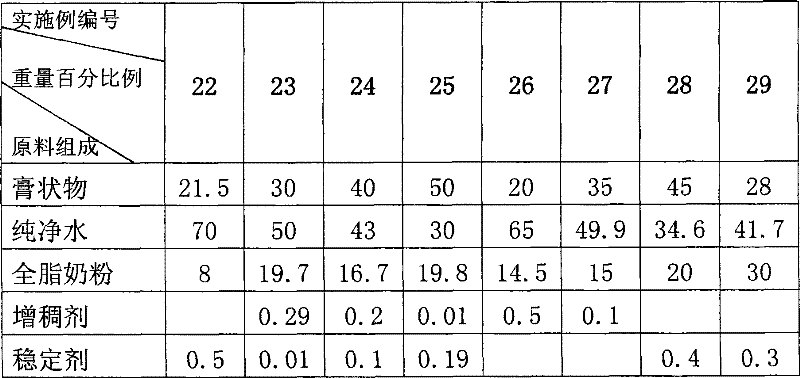

Pollen fruit milky tea and preparation thereof

InactiveCN101238841BImprove immunitySuitable for long-term consumptionMilk preparationPre-extraction tea treatmentFlavorLiquid product

The invention provides a pollen fruit milk tea, which is characterized in that: the mixture is composed of bee pollen or / and pollen 20-40wt%, fruit powder 10-40wt%, vegetable powder 1-10wt%, whole milk powder 10-39wt%, and tea polyphenol 0.5-1wt% and / or tea powder 5-30wt%; the preparation method includes: desiccating, griding and mixing ingredients, griding the mixture at 0-40 DEG C into powder whose diameter is less than 5 micron by supersonic airstream muller, and other processes; furthermore making the product into extract, liquid product. The product not only can be absorbed by human easily and can supply necessary nutrition that people need for metabolism, but also has no bitter, smelly, acerbity flavor, the taste is comfortable and soft, and is practical.

Owner:赖茂林

Preparation process of ZK61M magnesium alloy bar with diameter of 720 mm

ActiveCN108165784AIncrease productivitySolve technical difficultiesSecondary analysisProcess conditions

The invention discloses a preparation process of a ZK61M magnesium alloy bar with a diameter of 720 mm. The preparation process comprises the following steps of carrying out smelting, primary analysisand testing, refining, secondary analysis and testing, standing, and semi-continuous casting. According to the preparation process of the ZK61M magnesium alloy bar with the diameter of 720 mm, the production process conditions are strictly controlled, the technical difficulty in the production process is overcome, the production time is shortened, and the production efficiency of the magnesium alloy bar is improved, the production cost is reduced, and the produced finished product can fully meet the requirements of domestic and foreign markets.

Owner:洛阳晟雅镁合金科技有限公司

Monocrystal silicon wafer polishing process capable of obtaining high polishing rate

ActiveCN102962756BSpeed up thermal motionAccelerated corrosionPolishing machinesEngineeringForeign market

The invention relates to a monocrystal silicon wafer polishing process capable of obtaining a high polishing rate. In a coarse polishing process, an American Dupont SR330 coarse polishing solution is adopted, and diluted by pure water according to the ratio of 1:20 to 1:40; the flow is 23.5-24.5 L / min; a Rohm and Haas SUBA600 polishing pad is adopted; and the coarse polishing process comprises the following three steps: 1, using a coarse polishing solution to polish for 10 s, the rotating speed of a big disk being 23-27 rpm, the rotating speed of a central guide wheel being 48-52 rpm, and the pressure being 47-53 kPa; 2, using a coarse polishing solution to polish for 7-13 min, the rotating speed of the big disk being 38-42 rpm, the rotating speed of the central guide wheel being 78-82 rpm, and the pressure being 100-200 kPa; and 3, using pure water to polish for 40 s, the rotating speed of the big disk being 23+ / -27 rpm, the rotating speed of the central guide wheel being 48-52 rpm, and the pressure being 47-53 kPa. The polished section processed by the process has the removal rate up to 1.83-2.09 micron / min, which is far higher than the average level of 1 micron / min in the industry, and meanwhile, and has the pass percent up to more than 90% stably. The improvement of the productivity of the polished section can reduce the fixed cost, thereby meeting the requirements of domestic and foreign markets.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

Industrial synthesis method of TMBP

ActiveCN110105176AYield Double BoostDouble the purityOrganic chemistryOrganic compound preparationSynthesis methodsOxygen

The invention relates to an industrial synthesis method of TMBP. The method comprises the following steps of 1, dissolving 2,6-xylenol, sodium dodecyl sulfate and borax with isopropanol to obtain a preliminary solution for use; 2, adding a certain amount of deionized water in a reaction kettle, then adding the preliminary solution, after heating the mixture to a certain temperature, quickly addinga catalyst, then keeping the reaction kettle hermetic, conducting stirring, introducing oxygen, and continuously carrying out a reaction under certain pressure for a period of time; 3, after the reaction is finished, relieving pressure to normal pressure, and then conducting cooling, filtering, washing, re-crystallization and drying to obtain a white needle crystal product, namely the TMBP, wherein a reducing agent is added in the re-crystallization process. According to the industrial synthesis method, the process condition of pressurizing is innovatively adopted, the side reactions under the pressurizing condition are greatly reduced under the synergistic effect of the process condition of pressurizing and selection of types of raw materials and adjustment of the process condition, andthrough the further utilization of a reduction means, double increase of the yield (larger than 85% as a whole) and purity (larger than 99.0%) of the TMBP is achieved.

Owner:甘肃泰升化工科技有限公司

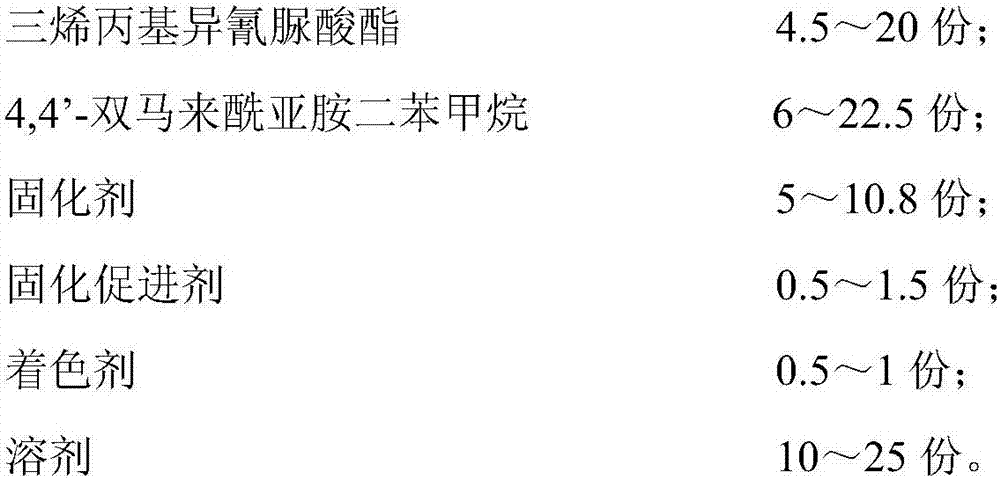

Phosphorus-containing nitrogen-containing halogen-free flame-retardation epoxy resin glue, prepreg and high temperature-resistant halogen-free flame-retardation insulation structural member

InactiveCN106916416AImprove mechanical propertiesImprove electrical performanceInsulating bodiesDiphenylmethaneEpoxy

The invention relates to a phosphorus-containing nitrogen-containing halogen-free flame-retardation epoxy resin glue, a prepreg and a high temperature-resistant halogen-free flame-retardation insulation structural member. The epoxy resin glue comprises the following raw materials in parts by weight: 40-60 parts of phosphorus-containing halogen-free epoxy resin; 4.5-20 parts of triallyl isocyanurate, 6-22.5 parts of 4,4'-bimaleimide diphenylmethane, 5-10.8 parts of a curing agent, 0.5-1.5 parts of a curing accelerator, 0.5-1 part of a colouring agent, and 10-25 parts of a solvent. The prepreg and the insulation structural member prepared by the epoxy resin glue have high temperature resistance (H grade), the flame resistance rate can reach an UL94 V-0 grade flame-retardation standard, the halogen total content is less than 500 PPM, the prepreg and the insulation structural member have excellent electrical performance, mechanical property, bonding property and heat resistance. The insulation structural member can be used for increasing the flame-retardation performance of a H-grade laminated board, increases the usage reliability, and can satisfy requirement of market at home and abroad.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Method for preparing solidified soil by utilizing soil stabilizer

The invention discloses a method for preparing solidified soil by using a soil stabilizer. The method comprises the following steps that raw materials and a mold are prepared, a prepared soil stabilizer is weighed according to a certain proportion, the weighed soil stabilizer is slowly put into a beaker with the volume of 1L, a proper amount of water is added for stirring, stirring is performed for 10 minutes, after uniformly stirred, a solution is diluted to 5-7 mol / L, a solution I containing the soil stabilizer is obtained, oil or vaseline is applied over the inner wall of the modle, so thatdemolding is facilitated, and the step of sealing and curing comprises the substeps of maintaining a temperature to be 20 DEG C-40 DEG C and the humidity to be 50 RH-70 RH in a curing period. The method for preparing solidified soil by using the soil stabilizer has the beneficial effects that the requirements of engineering construction development can be met, the degradation problem of pollutionis avoided, and the method has the advantages of simple processes, easiness in production expansion, no pollution, no harm and the like, is wide in raw material source, has extremely high commercialperformance, can be used repeatedly without side effects, and can well satisfy the domestic and overseas market demands.

Owner:苏云燕

Soil solidifying agent and preparation method thereof

InactiveCN111072364AHigh compressive strengthImprove waterproof and moisture-proof performanceSlagSolvent

The invention discloses a soil solidifying agent and a preparation method thereof. The soil solidifying agent comprises the following components: 25 to 40 parts of cement, 5 to 15 parts of fly ash, 5to 10 parts of water glass, 4 to 10 parts of calcium lignosulphonate, 15 to 25 parts of water, 2 to 6 parts of zeolite, 5 to 25 parts of polysaccharide, 4 to 10 parts of sodium silicate, 2 to 10 partsof sodium hydroxide, 5 to 15 parts of steel slag, 5 to 15 parts of chloride and 5 to 10 parts of a solubilizer, wherein the modulus of the water glass is 2.5 to 2.9. According to the soil solidifyingagent and the preparation method thereof, various components composed of the raw materials are matched and interact, and the effects of temperature, stirring and the like are utilized, so that the soil solidifying agent is obtained and is high in compressive strength, excellent in waterproof and moisture-proof performance, low in price, simple in preparation method, low in cost, wide in market prospect, suitable for large-scale production, extremely high in commercial performance, capable of being used repeatedly, free of side effects and capable of well meeting the market requirements at home and abroad.

Owner:南京化学工业园环保产业协同创新有限公司

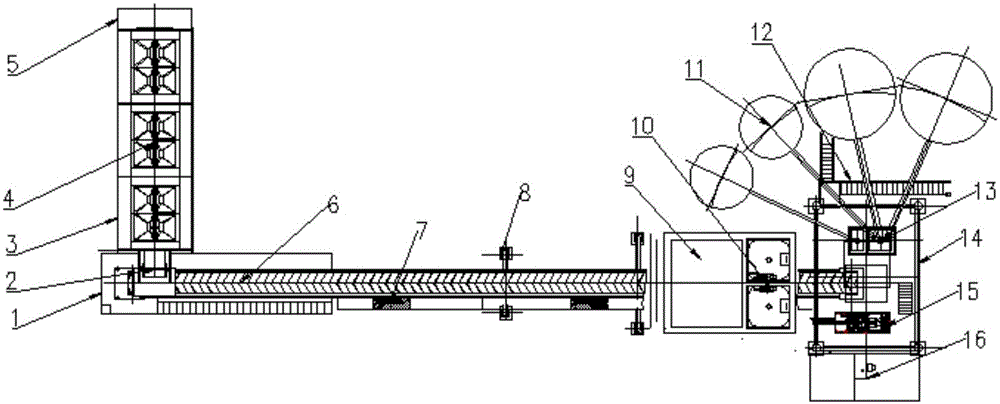

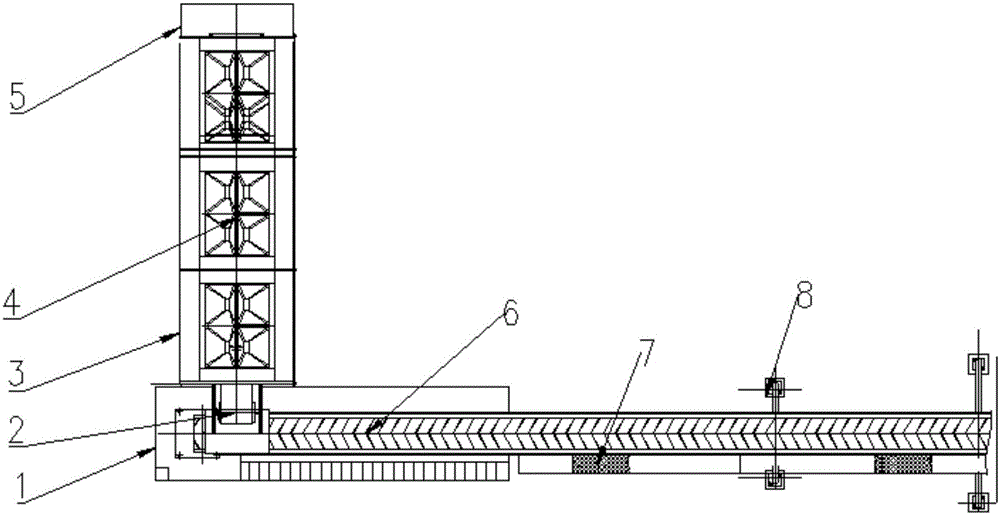

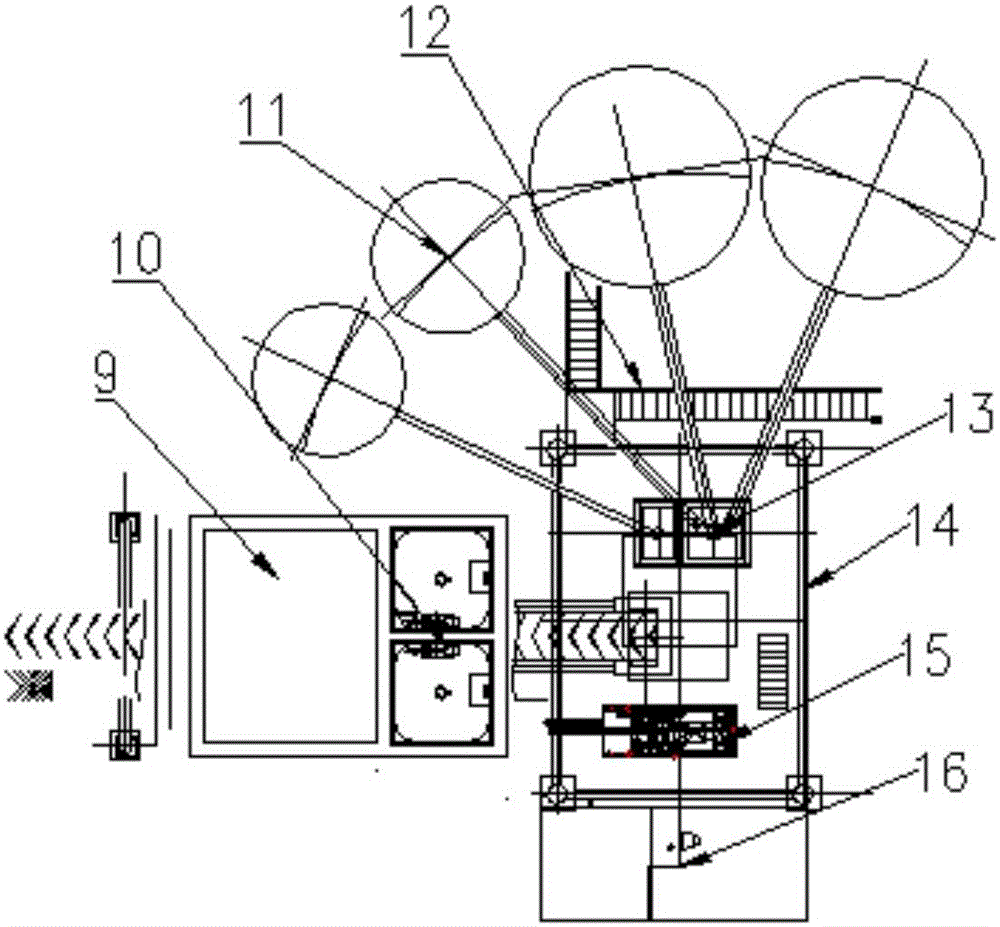

Large-scale automated cooling chemical apparatus for production of chemical raw materials

InactiveCN106406387AIncrease productionIncrease the production batchAuxillary controllers with auxillary heating devicesTemperature controlCooling tower

The invention relates to a large-scale automated cooling chemical apparatus for production of chemical raw materials. The large-scale automated cooling chemical apparatus comprises a fixed chassis, a cooling tower, an air-cooled refrigerating machine and a refrigerator storage chamber. A compression-type refrigerating unit is disposed above the fixed chassis. The cooling tower is arranged above the compression-type refrigerating unit. The inside of the cooling tower is provided with a composite condenser. An evaporator is arranged above the composite condenser. A transfer station is arranged above a manual detection table. A shape molding device is arranged above the transfer table. A sterilizing chamber is connected with a wrapping chamber. The air-cooled refrigerating machine is connected with an expansion valve. A thermal insulating board is disposed above the expansion valve. The refrigerator storage room is connected with a temperature controller. A dryer is arranged below the temperature controller. The invention has the beneficial effects of being capable of an increase in the production batch and automated operation, being capable of improving the production efficiency and saving manpower and financial resources, and greatly improving the production of chemical raw materials to meet the needs of domestic and foreign markets.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

Method for preparing mulberry brandy

ActiveCN102344868BRich varietyMeet the needs of domestic and foreign marketsAlcoholic beverage preparationDistillationTwo step

Owner:ZHEJIANG PHARMA COLLEGE

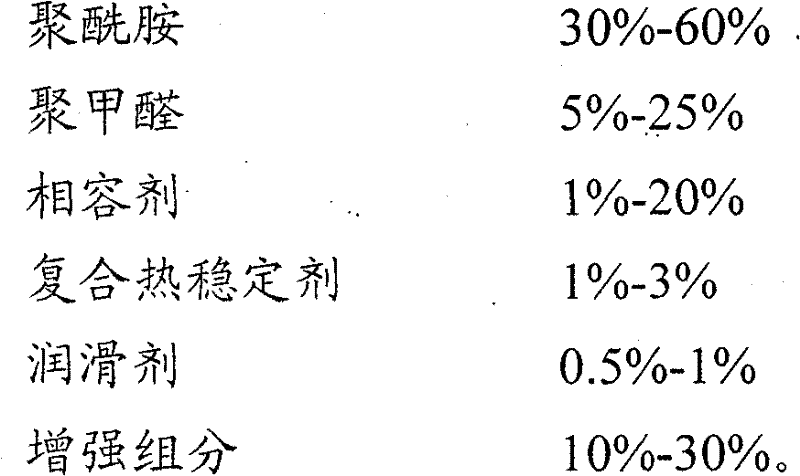

Wear-resistant reinforced polyamide/polyoxymethylene alloy material and preparation method thereof

InactiveCN101805515BImprove wear resistanceImprove mechanical propertiesPolyoxymethyleneWear resistant

The invention discloses a wear-resisting reinforced polyamide / polyoxymethylene alloy. The weight percentage of raw materials is as follows: 30%-60% of polyamide, 5%-25% of polyoxymethylene, 1%-20% of compatibilizer, compound Heat stabilizer 1.0%-3.0%, lubricant 0.5%-1.0% and reinforcing component 10%-30%. The alloy has excellent wear-resistant self-lubrication and mechanical properties, good dimensional stability, easy injection molding, adjustable color, and can well meet the needs of domestic and foreign markets. The preparation method has simple operation and is suitable for industrialized production.

Owner:CGN JUNER NEW MATERIALS +1

Preparation method of graphene-based carbon dioxide trapping agent

InactiveCN111085167AMeet capture needsMeet the needs of domestic and foreign marketsGas treatmentOther chemical processesPhysical chemistryGraphene

The invention discloses a preparation method of a graphene-based carbon dioxide trapping agent. The graphene-based carbon dioxide scavenger has the following components and contents: SiC:20-23.5 wt%,CuO:0.1-0.3 wt%, cO2:20-30 wt%, Fe(OH)2: 20-34 wt%, Mn:1.03-0.14 wt%, Zn:0.03-0.04 wt%, Ag:0.003-0.004 wt%, Wu:100-150ppm, and the balance being excess NH3 and CO2 generated in the process. The deposition process of introduced carbon dioxide gas is controlled for 1-50 minutes; preferred 5-10 min, wherein the external temperature is kept at 10 to 100 DEG C; preferred 25 degrees. The beneficial effects of the preparation method are that: ammonia gas and carbon dioxide are utilized; the graphene powder capable of reacting is added and combined to prepare the fine degradation trapping agent, suchthat the capturing requirement on greenhouse gas can be well met, the multi-time use can be achieved, no by-product is generated, and the domestic and overseas market requirements can be well met.

Owner:南京化学工业园环保产业协同创新有限公司

A method for preparing water-solubility ginkgo powder

InactiveCN101156703BHistoricalSufficiently retain the nutritional ingredients of medicinal dietMilk preparationFood preparationCyanide compoundSolubility

The invention relates to a production method of a water soluble gingko powder, which belongs to the gingko processing technical field. The invention takes fresh gingko as the raw materials, gingko seeds are crushed with water after being shelled, the gingko starch and the destarch gingko solution are respectively obtained through precipitation separation, the gingko starch obtains the gingko starch hydrolyzed solution through the enzymolysis of amylase and pullulanase together, and the gingko starch hydrolyzed solution and the destarch gingko solution adopt homogenization treatment and spray drying after being mixed, so as to produce water soluble gingko powder of the residual of non-cyanide. The water soluble gingko powder holds the gingko fragrance and the nutrition component, thereby the invention has great significance to the comprehensive utilization of gingko resources.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com