Wear-resistant reinforced polyamide/polyoxymethylene alloy material and preparation method thereof

An alloy material, polyamide technology, applied in the field of wear-resistant reinforced polyamide/polyoxymethylene alloy material and its preparation, can solve the problems of reducing the strength and toughness of the material, the lack of any compatibility of nylon, and the reduction of the mechanical properties of the material. Easy injection molding, excellent wear resistance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

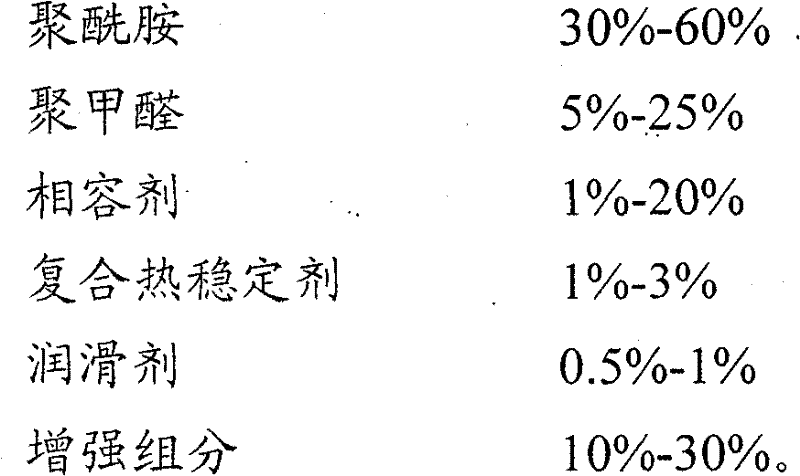

[0035] The raw material ratio is as follows:

[0036] PA66 (EPR28 Shenma) 53.5Kg

[0037] Polyoxymethylene (90-04 Polyplastics) 15Kg

[0038] POE-g-MHA (Light of Energy) 5Kg

[0039] Antioxidant 1098 (hindered phenol stabilizer Yabao) 0.3Kg

[0040] Antioxidant 168 (phosphite stabilizer Yabao) 0.4Kg

[0041] Cuprous iodide 0.3kg

[0042] Magnesium Stearate 0.5Kg

[0043]E-glass fiber 25Kg

[0044] Preparation of wear-resistant reinforced polyamide / polyoxymethylene alloy material:

[0045] Mix polyamide 66 and polyoxymethylene resin in a high-speed mixer (rotating speed 2000r / min) for 2 minutes according to the above-mentioned material ratio to make them evenly mixed, then feed them into the twin-screw extruder from the first feeder (main feeder), and POE -g-MHA, antioxidant 1098, antioxidant 168, cuprous iodide and magnesium stearate are mixed by a high-speed mixer (rotating speed 2500r / min) for 3 minutes to make them evenly mixed and then added to the twin-screw extrud...

Embodiment 2

[0048] The raw material ratio is as follows:

[0049] PA66 (EPR28 Shenma) 28.5Kg

[0050] PA6 (M2400 Xinhui Meida) 25Kg

[0051] Polyoxymethylene (90-04 Polyplastics) 15Kg

[0052] EPDM-g-MHA (Light of Energy) 5Kg

[0053] Antioxidant 1098 (hindered phenol stabilizer Yabao) 0.4Kg

[0054] Antioxidant 168 (phosphite stabilizer Yabao) 0.3Kg

[0055] Cuprous iodide 0.3kg

[0056] Magnesium Stearate 0.5Kg

[0057] E-glass fiber 25Kg

[0058] Mix polyamide 66, PA6 and polyoxymethylene resin in a high-speed mixer (rotating speed 2000r / min) for 2 minutes according to the above material ratio to make them evenly mixed, and then feed them into the twin-screw extruder from the first feeder (main feeder). Mix EPDM-g-MHA, antioxidant 1098, antioxidant 168, cuprous iodide and magnesium stearate by a high-speed mixer (rotating speed 2500r / min) for 3 minutes to make them evenly mixed and then add them into the twin-screw by the second feeder extruder, and the alkali-free glass fiber ...

Embodiment 3

[0061] The raw material ratio is as follows:

[0062] PA6 (M2400 Xinhui Meida) 53.5Kg

[0063] Polyoxymethylene (90-04 Benbaoli) 15Kg

[0064] PE-g-MHA (Energy Light) 5Kg

[0065] Antioxidant 1098 (hindered phenol stabilizer Yabao) 0.4Kg

[0066] Antioxidant 168 (phosphite stabilizer Yabao) 0.3Kg

[0067] Cuprous iodide 0.3kg

[0068] Magnesium Stearate 0.5Kg

[0069] E-glass fiber 25Kg

[0070] Mix PA6 and polyoxymethylene resin in a high-speed mixer (rotating speed 2000r / min) according to the above-mentioned material ratio for 2 minutes to make them evenly mixed, then feed them into the twin-screw extruder from the first feeder (main feeder), and mix PE-g -MHA, antioxidant 1098, antioxidant 168, cuprous iodide and magnesium stearate were mixed by a high-speed mixer (rotating speed 2500r / min) for 3 minutes to make it evenly mixed and then added into the twin-screw extruder by the second feeder, And the alkali-free glass fiber is fed into the twin-screw extruder from th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com