A method for preparing water-solubility ginkgo powder

A production method, ginkgo powder technology, applied in food preparation, dairy products, food science, etc., can solve the problems of limited living space of enterprises, limited shelf life of products, limited processing capacity of enterprises with huge ginkgo production, and achieve obvious economic benefits and social benefits. Benefits, the effect of broadening product models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

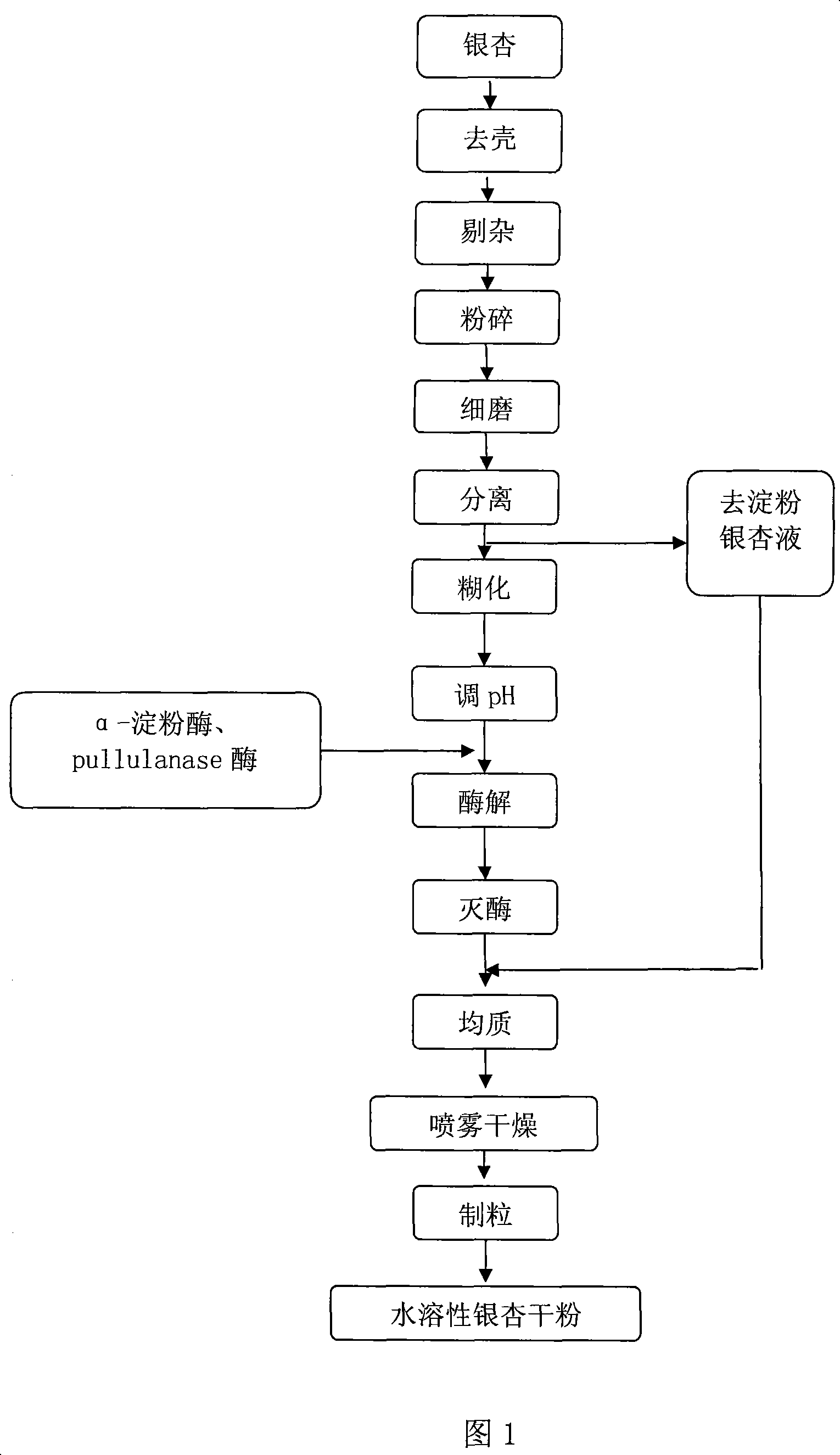

Image

Examples

Embodiment 1

[0031] 1 ton of fresh ginkgo fruit is mechanically removed from the outer testa and shell to obtain 270 kg of ginkgo kernels. The ginkgo seeds enter the coarse mill, add 500 kg of water, crush through a 80-mesh sieve, and separate the centrifuge pulp and slag. The slag enters the coarse grinding section for re-grinding. Slag, centrifuge speed 8000 rpm, continuous feeding and continuous slag discharge, 12 kg of slag discharge. The slag-removed slurry enters the sedimentation tank to separate the starch, and after standing for 8 hours, the ginkgo aqueous solution is sucked out, and the starch is separated separately. The starch is reserved for enzymatic hydrolysis, and the ginkgo water-soluble substances are used for later use. Control the content of ginkgo water-soluble substances to be greater than 30%, and the water content of the starch reserved for enzymatic hydrolysis is not less than 40%. The precipitated starch is sent to the heat exchange by a sanitary pump to raise t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com