Anti-hardener for high-stability crystal ammonium nitrate without demulsification

A high-stability, hardener technology, used in non-explosive/non-thermal components, offensive equipment, explosives, etc., to solve problems such as caking, insignificant effects, and incompatibility of emulsifiers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

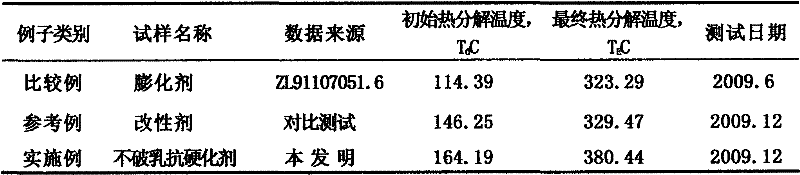

Examples

Embodiment Construction

[0025] 1 implement according to the following optimal composition (mass %):

[0026] 60 Crystal control agent: octyltrimethylammonium chloride

[0027] 15 Stabilizer: sodium benzyl naphthalene sulfonate

[0028] 20 Moisture-proof agent: polyethylene glycol

[0029] 5 Anti-sticking agent: erucamide

[0030] Preparation of the present invention: first four kinds of raw materials of octyltrimethylammonium chloride 300Kg, sodium benzylnaphthalene sulfonate 75Kg, polyethylene glycol 100Kg and erucamide 25Kg, which have been weighed in proportion, are loaded into the In the jacketed stainless steel reaction kettle of the device and temperature measurement system, heat it with steam to 90-100 ° C to melt into a uniform and transparent state, and stir and keep it at 90-100 ° C for 20-25 minutes, then discharge the material, cool and solidify into a brown solid The blocky material is then processed into a thin flake anti-hardening agent with a thickness of about 0.5-1.0mm by a rolli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Packing density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com