High-looseness high-sensitivity ammonium nitrate fuel oil explosive for explosion welding and preparation method thereof

A technology of high-sensitivity ammonium oil and explosive welding, which is applied in the direction of explosives, can solve the problems of anti-caking and improvement of detonation sensitivity that have not been completely successful, and achieve the effects of excellent fluidity of explosives, safe and convenient use, and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

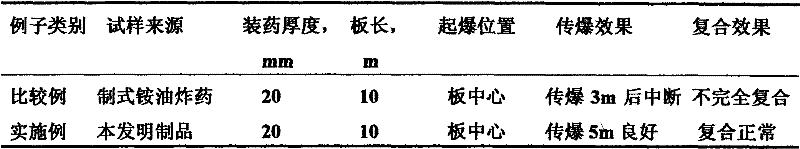

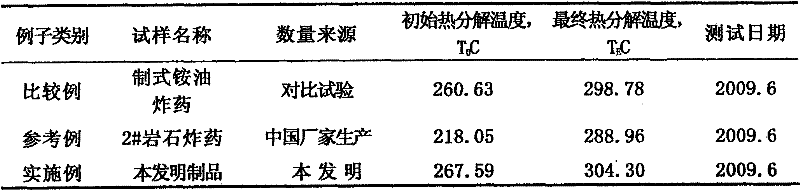

Examples

Embodiment Construction

[0038] 1 implement according to the best formula (mass %) as follows:

[0039] 94 Porous granular ammonium nitrate

[0040] 5.7 Fuel oil

[0041] 0.3 Composite improver

[0042] Wherein the composite improver is implemented by the following optimum composition (mass %);

[0043] 70 Crystal modifier: octadecyl primary amine borate

[0044] 15 Dispersant: Sodium Methylene Dimethyl Naphthalene Sulfonate

[0045] 6 Lubricant: stearic acid

[0046] 8 Adsorbent: sepiolite

[0047] 1 Neutralizing agent: urea

[0048] Preparation of composite improver: First, bake 8kg of sepiolite in an oven at 80-90°C for 4 hours, then put 70kg of octadecyl primary amine borate and 6kg of stearic acid in a ball mill with a rotation speed of 40r / min Pulverize, the fineness needs to be more than 425 μm and 80% or more; then add the above three qualified raw materials together with 15 kg of dispersant sodium methylene bismethylnaphthalene sulfonate and 1 kg of urea into a double-layer spiral stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com