Preparation method of thermoplastic polyurethane elastomer for reactive hot melt adhesive

A technology of thermoplastic polyurethane and hot melt adhesive, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc. Insufficient initial adhesive strength of melt adhesive, adverse effects of operating temperature and opening time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

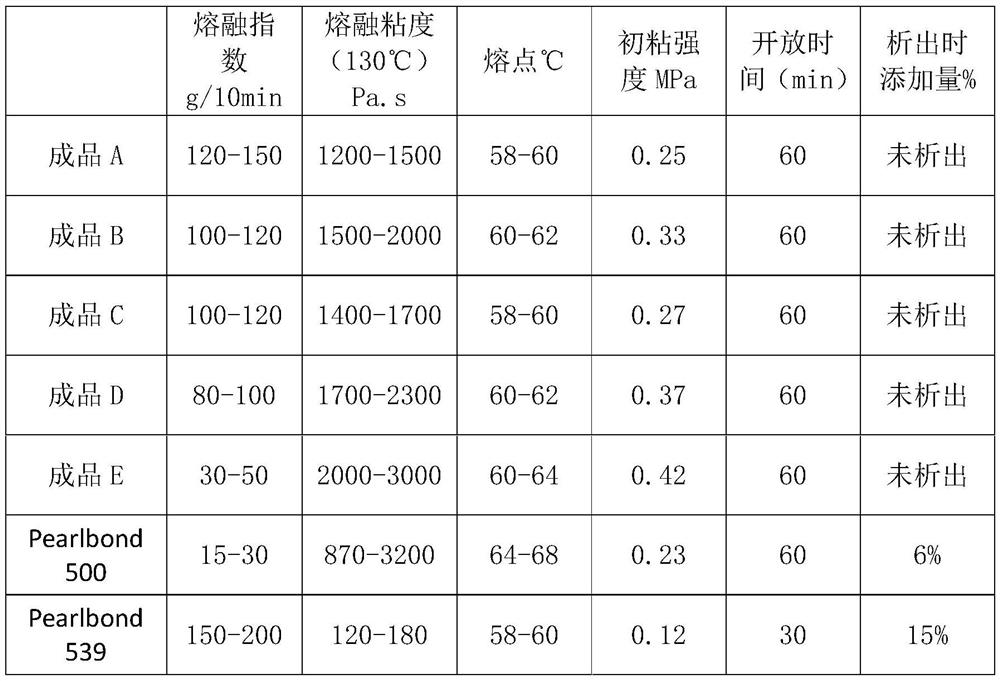

Examples

Embodiment 1

[0038] Step 1. Add 80kg of polyester polyol and 5kg of two-terminal hydroxyl polybutadiene to the reactor, wherein polyester polyol is made of polyester polyol P-5 40kg, polyester polyol 356T 25kg, polyester polyol Dynacoll 7130 15kg is mixed, the temperature is controlled at 120°C, the vacuum degree is ≤0.095MPa, and the vacuum dehydration is 2-3h to obtain the mixture;

[0039] Step 2, after dehydration treatment, cool the mixture of step 1 to 80°C, add 15kg of dimer acid diisocyanate, 0.5kg of zinc octylate, 1.0kg of antioxidant 1010 and 2-hydroxy-4-methylbenzidine into the reaction kettle Ketone 1.0kg, stirred at 90r / min, mixed evenly, at 85°C, vacuum degree ≤ 0.095MPa, stirred at 90r / min for 3h; obtained thermoplastic polyurethane elastomer for reactive polyurethane hot melt adhesive;

[0040] Step 3: Packaging and sealing the thermoplastic polyurethane elastomer in step 2 under the protection of nitrogen to isolate oxygen and water vapor to obtain a finished thermoplasti...

Embodiment 2

[0042] Step 1. Add 60kg of polyester polyol and 10kg of two-terminal hydroxyl polybutadiene to the reaction kettle, wherein polyester polyol is made of polyester polyol P-5 30kg, polyester polyol 356T 28kg, polyester polyol Dynacoll 7130 12kg is mixed, the temperature is controlled at 120°C, the vacuum degree is ≤0.095MPa, vacuum dehydration is 2-3h, and the mixture is obtained;

[0043]Step 2, after dehydration treatment, cool the mixture of step 1 to 80°C, add 30kg of dimer acid diisocyanate, 0.5kg of zinc octanoate, 1.0kg of antioxidant 1010 and 2-hydroxy-4-methylbenzophenone to the reaction kettle 1.0kg, 100r / min stirring and mixing evenly, at 85℃, vacuum degree ≤ 0.095MPa, 100r / min stirring reaction for 3h; obtain thermoplastic polyurethane elastomer for reactive polyurethane hot melt adhesive;

[0044] Step 3: Packaging and sealing the thermoplastic polyurethane elastomer in step 2 under the protection of nitrogen to isolate oxygen and water vapor to obtain a finished th...

Embodiment 3

[0046] Step 1. Add 80kg of polyester polyol and 5kg of two-terminal hydroxyl polybutadiene to the reactor, wherein the polyester polyol is composed of polyester polyol 224 38kg, polyester polyol CMA-2066 25kg, polyester polyol Mix 17kg of alcohol P-153, control the temperature at 120°C, vacuum degree ≤0.095MPa, and vacuum dehydrate for 2-3h to obtain the mixture;

[0047] Step 2, after dehydration treatment, cool the mixture of step 1 to 80°C, add 15kg of dimer acid diisocyanate, 0.5kg of zinc octylate, 1.0kg of antioxidant 1010 and 2-hydroxy-4-methylbenzidine into the reaction kettle Ketone 1.0kg, stirred at 100r / min and mixed evenly, stirred and reacted at 100r / min at 85°C and vacuum ≤0.095MPa for 3h; obtained thermoplastic polyurethane elastomer for reactive polyurethane hot melt adhesive;

[0048] Step 3: Packaging and sealing the thermoplastic polyurethane elastomer in step 2 under the protection of nitrogen to isolate oxygen and water vapor to obtain a finished thermopla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com