Phosphorus-containing nitrogen-containing halogen-free flame-retardation epoxy resin glue, prepreg and high temperature-resistant halogen-free flame-retardation insulation structural member

A technology of epoxy resin glue and halogen epoxy resin, applied in insulators, insulators, electrical components, etc., can solve problems such as lack of mechanical properties, achieve excellent electrical properties, improve flame retardant properties, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

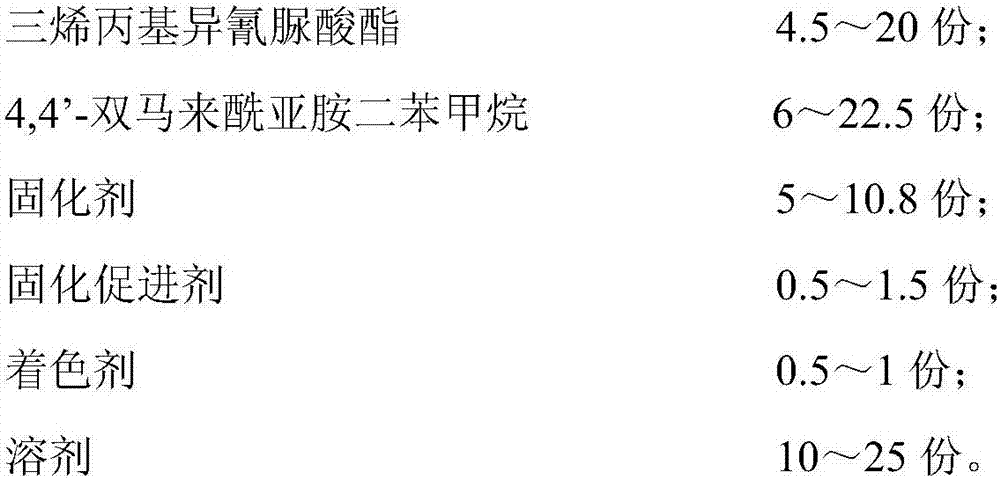

Method used

Image

Examples

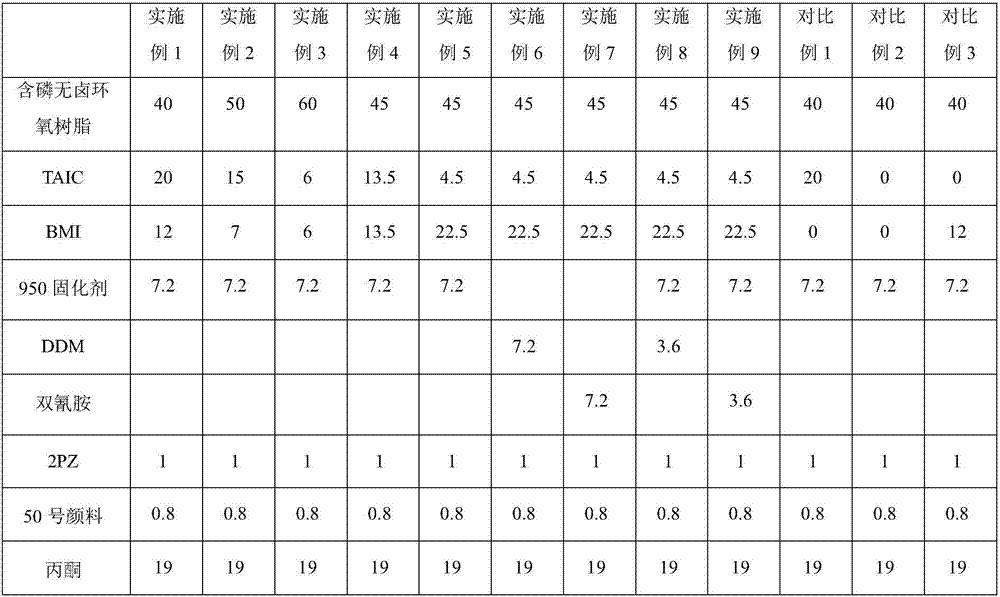

Embodiment 1

[0040] This example provides a phosphorus-containing nitrogen-containing halogen-free flame-retardant epoxy resin glue, and the raw material formula is shown in Table 1. The phosphorus-containing nitrogen-containing halogen-free flame-retardant epoxy resin glue is prepared by the following steps: Accurately weigh 40 mass One part of phosphorus-containing halogen-free epoxy resin is placed in a reaction kettle equipped with a motor-mechanical stirrer, a thermocouple, and a reflux condenser. Turn on the stirrer, turn on the thermocouple to heat the epoxy resin at 100°C, and then add 20 Parts by mass of triallyl isocyanurate (TAIC) and 12 parts by mass of 4,4'-bismaleimide diphenylmethane (BMI) were stirred for 1 hour until uniform dispersion. Then slowly add 7.2 parts by mass of 950 curing agent and 1 part by mass of 2PZ, and continue stirring for 2 hours to fully disperse the curing agent and curing accelerator. After cooling down to 40° C., 0.8 parts by mass of No. 50 green pi...

Embodiment 2

[0046] This example provides a phosphorus-containing nitrogen-containing halogen-free flame-retardant epoxy resin glue, and the raw material formula is shown in Table 1. The phosphorus-containing nitrogen-containing halogen-free flame-retardant epoxy resin glue is prepared by the following steps: Accurately weigh 50 mass One part of phosphorus-containing halogen-free epoxy resin is placed in a reaction kettle equipped with a motor-mechanical stirrer, a thermocouple, and a reflux condenser. Turn on the stirrer, turn on the thermocouple to heat the epoxy resin at 90°C, and then add 15 Parts by mass of TAIC and 7 parts by mass of BMI were stirred for 2 hours until uniform dispersion. Then slowly add 7.2 parts by mass of 950 curing agent and 1 part by mass of 2PZ, and continue stirring for 1 hour to fully disperse the curing agent and curing accelerator. After cooling down to 50° C., 0.8 parts by mass of No. 50 green pigment and 19 parts by mass of acetone were added, and then ful...

Embodiment 3

[0049] This example provides a phosphorus-containing nitrogen-containing halogen-free flame-retardant epoxy resin glue, and the raw material formula is shown in Table 1. The phosphorus-containing nitrogen-containing halogen-free flame-retardant epoxy resin glue is prepared by the following steps: Accurately weigh 60 mass One part of phosphorus-containing halogen-free epoxy resin is placed in a reaction kettle equipped with a motor mechanical stirrer, a thermocouple, and a reflux condenser. Turn on the stirrer, turn on the thermocouple to heat the epoxy resin at 90°C, and then add 6 Parts by mass of TAIC and 6 parts by mass of BMI were continuously stirred for 1.5 h until the dispersion was uniform. Then slowly add 7.2 parts by mass of 950 curing agent and 1 part by mass of 2PZ, and continue stirring for 1.5 hours to fully disperse the curing agent and curing accelerator. After cooling down to 45° C., 0.8 parts by mass of No. 50 green pigment and 19 parts by mass of acetone wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com