Raw paper for dispersed wet tissues and production method for raw paper

A technology for wet tissue paper and base paper, which is applied in the directions of synthetic cellulose/non-cellulose material pulp/paper, papermaking, textiles and papermaking, etc. The effect of reducing production cost, improving effect and hydrolyzability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

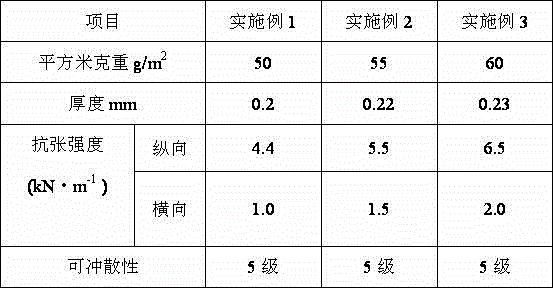

Examples

Embodiment 1

[0022] A method for manufacturing a flushable wet tissue paper base paper, comprising the following steps:

[0023] a. Papermaking process: after the pure wood pulp is disintegrated by a hydropulper, it is disintegrated and beaten to obtain a wood pulp slurry with a concentration of 2.5 wt% and a degree of percussion of 18oSR; Mix with wood pulp slurry in the pulp tank, and finally prepare papermaking slurry consisting of 35% wood pulp fiber, 25% polylactic acid fiber, and 40% coconut charcoal fiber according to the dry pulp ratio, and the concentration of papermaking slurry is controlled at 1.5 wt % Add papermaking special dispersant accounting for 0.5% of the total weight of papermaking slurry to the papermaking slurry for batching, then pass through the inclined wire papermaking wire part former, press dehydration, and dry the base paper to obtain the base paper;

[0024] b. Spunlace entanglement process: The base paper obtained in the papermaking process is treated with sp...

Embodiment 2

[0028] A method for manufacturing a flushable wet tissue paper base paper, comprising the following steps:

[0029] a. Papermaking process: after the pure wood pulp is disintegrated by a hydropulper, it is disintegrated and beaten to obtain a wood pulp slurry with a concentration of 2.5 wt% and a degree of percussion of 18oSR; Mix with wood pulp slurry in the pulp tank, and finally prepare papermaking slurry consisting of 30% wood pulp fiber, 28% polylactic acid fiber, and 42% coconut charcoal fiber according to the dry pulp ratio, and the concentration of papermaking slurry is controlled at 1.5 wt % ; Add papermaking special dispersant accounting for 0.6% of the total weight of papermaking slurry to the papermaking slurry for batching, then pass through the inclined wire papermaking wire part former, press dehydration, and dry the base paper to obtain the base paper;

[0030] b. Spunlace entanglement process: the base paper obtained in the papermaking process is spunlace enta...

Embodiment 3

[0034] A kind of manufacturing method of the base paper of flush type wet tissue paper, specifically is the following steps:

[0035]a. Papermaking process: after the pure wood pulp is disintegrated by a hydropulper, it is disintegrated and beaten to obtain a wood pulp slurry with a concentration of 3.0 wt% and a degree of percussion of 20oSR; Mix with wood pulp slurry in the pulp tank, and finally prepare papermaking slurry consisting of 35% wood pulp fiber, 25% polylactic acid fiber, and 40% coconut charcoal fiber according to the dry pulp ratio, and the concentration of papermaking slurry is controlled at 1.2 wt % Add papermaking special dispersant accounting for 0.5% of the total weight of papermaking slurry to the papermaking slurry for batching, then pass through the inclined wire papermaking wire part former, press dehydration, and dry the base paper to obtain the base paper;

[0036] b. Spunlace entanglement process: the base paper obtained in the papermaking process i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com