Submerged nozzle control method of bar strip continuous casting

A thin slab continuous casting and control method technology, which is applied in the control field of thin slab continuous casting submerged nozzles, can solve the problems that the nozzle cannot reach the design life and the nozzle erosion is uneven, so as to shorten the erosion time, reduce the perforation rate, prolong the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

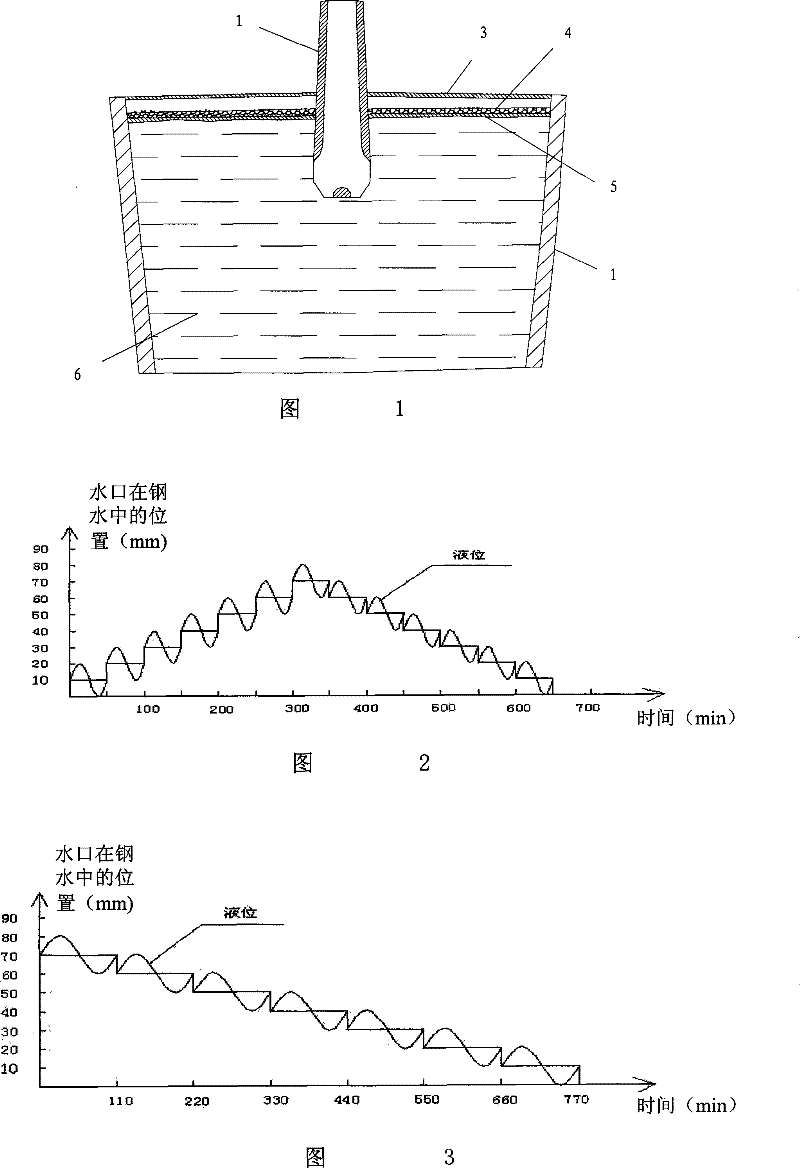

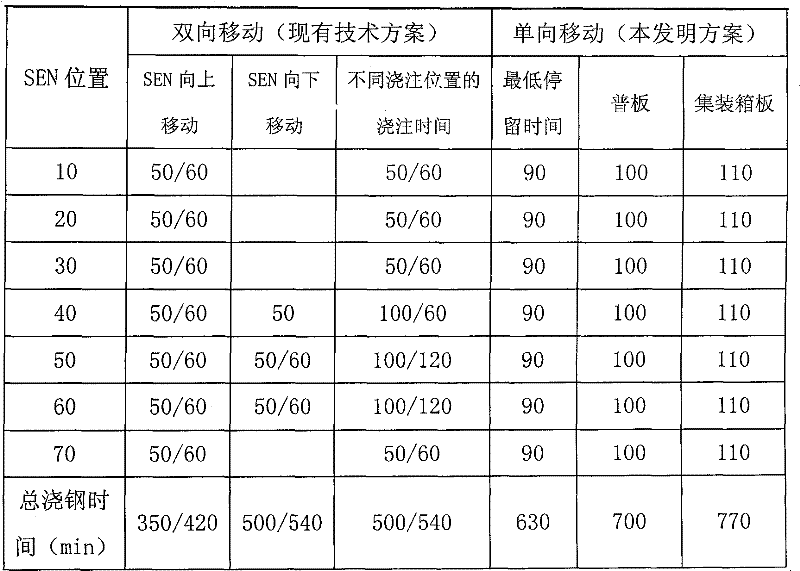

[0016] refer to image 3 , a thin slab continuous casting submerged nozzle control method of the present invention, slag adjustment is carried out seven times, and the erosion range is set to 10-70mm according to the nozzle (SEN) 1. When the casting machine passes through the shearing machine, the nozzle is controlled in one direction 1. After each slag adjustment cycle, the one-way downward movement step is 10mm. During the entire slag adjustment process, the moving position of nozzle 1 changes in the order of 70mm, 60mm, 50mm, 40mm, 30mm, 20mm, and 10mm. The period of adjusting the liquid level fluctuation in the crystallizer 2 is the same as that of each slag adjustment period, which is 100-120 minutes. Control the fluctuation range of the liquid level in the crystallizer 2 to be less than or equal to the single movement step of the nozzle 1.

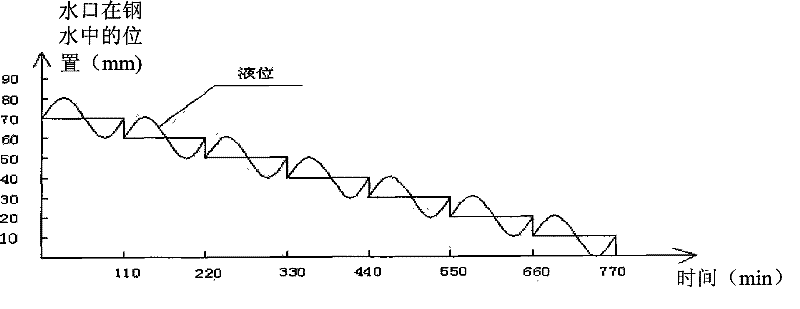

[0017] The beneficial effects of the present invention will be further described below with reference to the prior art and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com