Touch panel, preparation method thereof and electronic equipment

A touch panel and electrode technology, applied in the field of electronics, can solve problems such as side corrosion of conductive metal layer lines, and achieve the effects of reducing side corrosion, solving line side corrosion, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

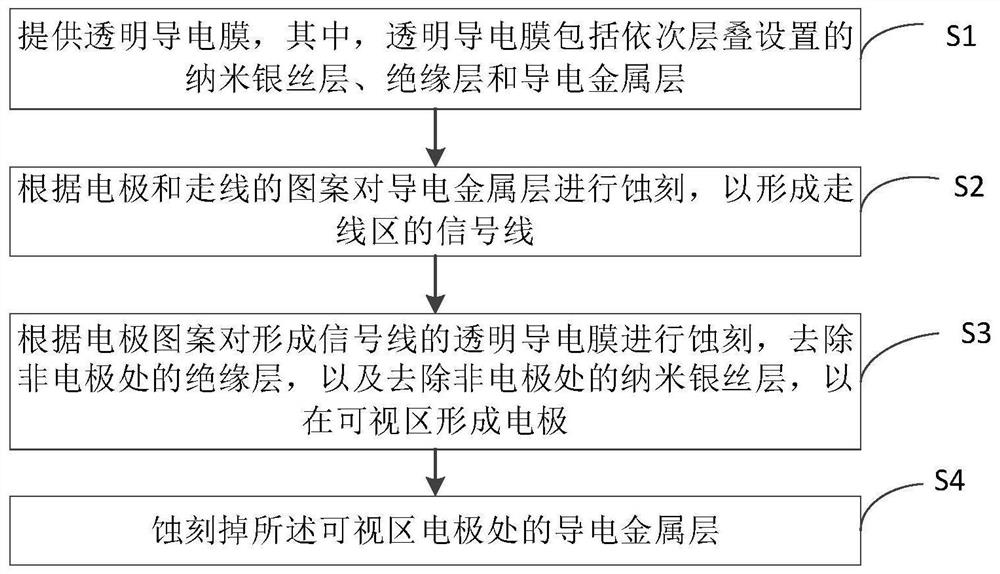

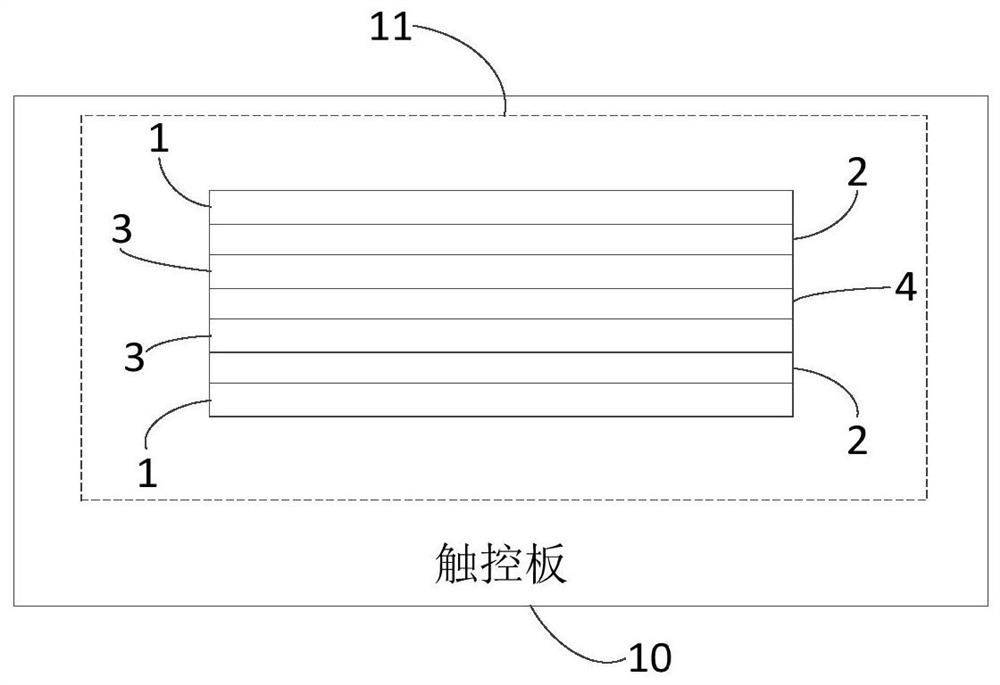

[0042]According to the preparation method of the touch panel according to the embodiment of the present invention, based on the etchable insulating layer, when preparing the electrode, the insulating layer at the non-electrode position is etched away, that is, the barrier of the nano-silver wire layer corresponding to the non-electrode position is removed, thereby , when the nano-silver layer is etched, the etching speed of the nano-silver layer is improved, which is equivalent to shortening the erosion time on the side of the signal line formed by the conductive metal layer, reducing the side erosion of the signal line, and effectively solving the problem of The side erosion of the conductive metal layer due to the slow etching of the nano-silver layer is beneficial to improving the precision of the preparation process and improving the stability of the performance of the touch panel.

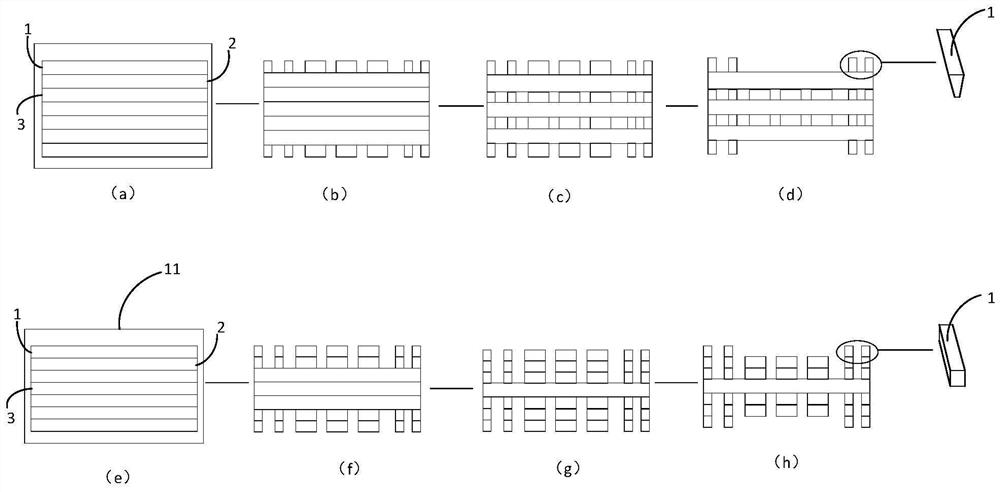

[0043] For example, if figure 2 as shown, figure 2 (a)-(d) is the process flow of etchi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com