Aluminium alloy extruded section microstructure examination method and electrode used for preparation of metallographic samples

A technology for microstructure and extruded profiles, which is applied in the field of inspection methods for the microstructure of aluminum alloy extruded profiles and electrodes for preparing metallographic samples, which can solve the problems of accuracy and efficiency not meeting the requirements, acid-base solution erosion Long time, micrograin boundaries are not obvious, etc., to improve the overall dark, conducive to detection and judgment, shorten the effect of erosion time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

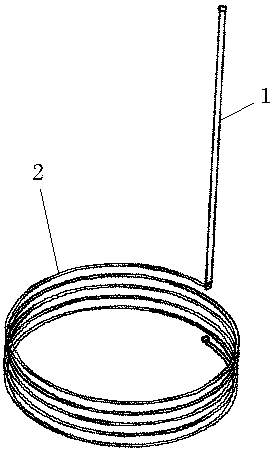

[0039] The electrode used to prepare the metallographic sample in the inspection method of the following example includes a power connection rod 1 connected to the power supply cathode and a spiral immersion end 2 immersed in the electrolyte, and the power connection rod 1 and the spiral immersion end 2 are integrally formed. , the helical immersion end 2 is a cylindrical helical spring structure.

[0040] The power connecting rod 1 is perpendicular to the cylindrical upper surface of the spiral immersion end 2 .

[0041] The outer diameter of the spiral immersion end 2 is 90mm, and the height is about 35mm. When in use, the spiral immersion end 2 is completely immersed in the electrolyte, and the diameter of the electrolytic cell is 100mm, and the height is 80mm.

[0042] The power connecting rod 1 and the spiral immersion end 2 are made of stainless steel, preferably 316L stainless steel. The diameter of the stainless steel rod used for preparing the electrode is 3-4 mm, wh...

Embodiment 2

[0044] A method for testing the metallographic microstructure of an aluminum alloy extruded profile, the steps of which are as follows:

[0045] (1) Test preparation

[0046] a) The oxidation electrolysis device adopts a special stainless steel cathode spiral electrolysis plate, an adjustable DC power supply, and a hair dryer;

[0047] b) Optical microscope with polarized light and Lambda filter and supporting analysis software;

[0048] c) Reagent: 30% nitric acid solution, 99.7% alcohol (C 2 h 5 OH), perchloric acid (HClO 4 );

[0049] (2) Preparation of metallographic samples

[0050] a) Mill the surface of the sample to be observed (series 6 aluminum alloy) with a roughness not greater than 1.6um.

[0051] b) Polish the surface of the sample with 1000 and 2000 mesh sandpaper respectively until the surface is smooth and there are no obvious machining traces.

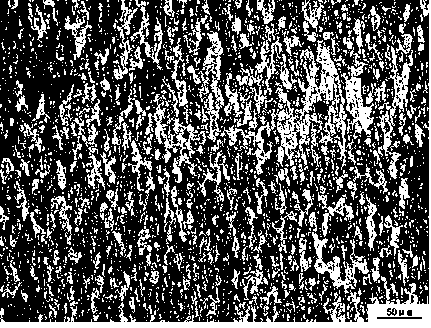

[0052] c) Grind and polish the sample with a woolen cloth until the surface appears a mirror surface without...

Embodiment 3

[0066] The difference between this embodiment and Embodiment 2 is that the parameter setting of the DC power supply is determined, the voltage is set to 40V, and the current is 1.8A.

[0067] The difference between this embodiment and Example 2 is that the depressurization speed is set to 1.5V / s, which is suitable for aluminum alloys with a large content of the second phase, and other steps and parameters are the same as those in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com