Milling machine special for magnetic turning guideway

A special milling machine and guide rail technology, which is applied in the direction of milling machine equipment, milling machine equipment details, large fixed members, etc., can solve the problems of inconvenient popularization and high price, and achieve the effect of convenient milling speed, easy operation and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

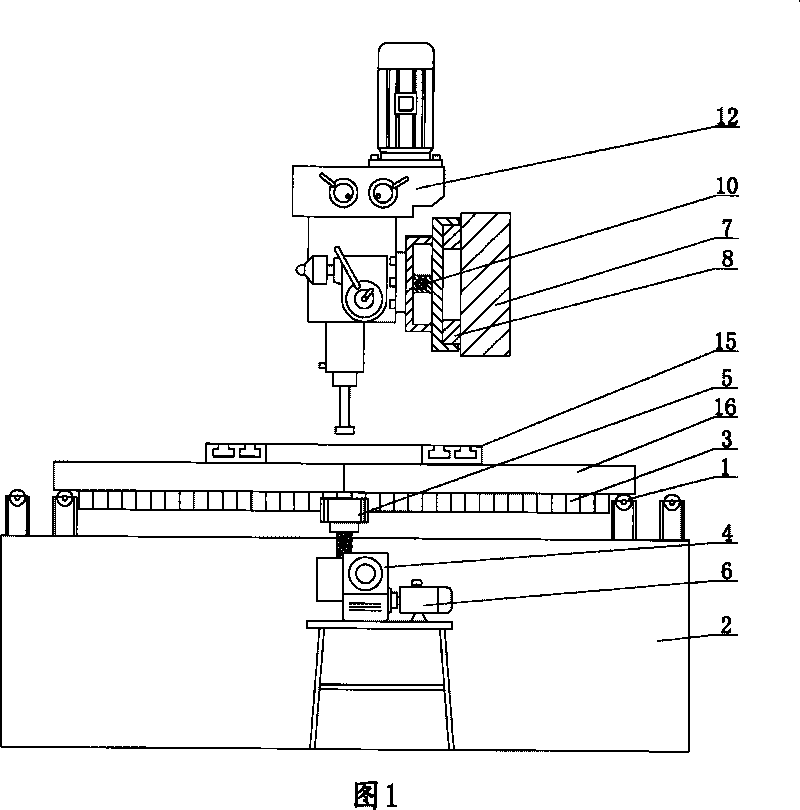

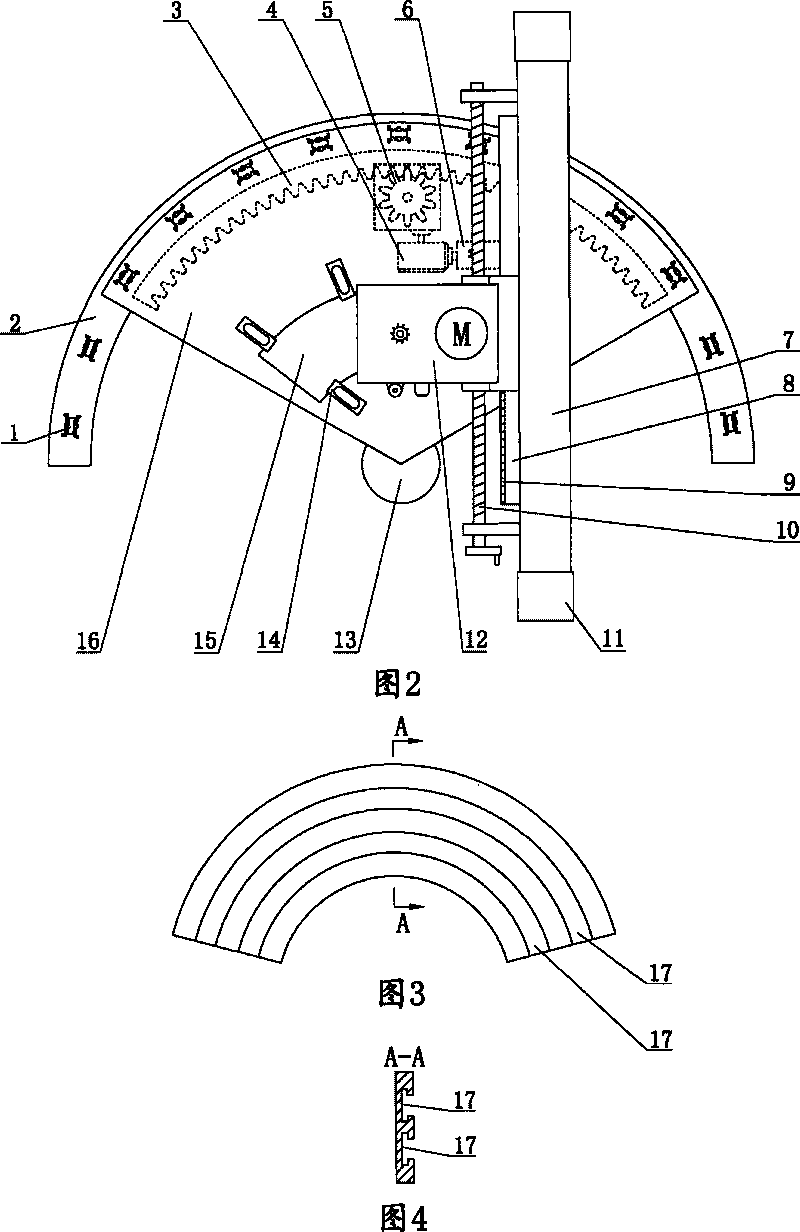

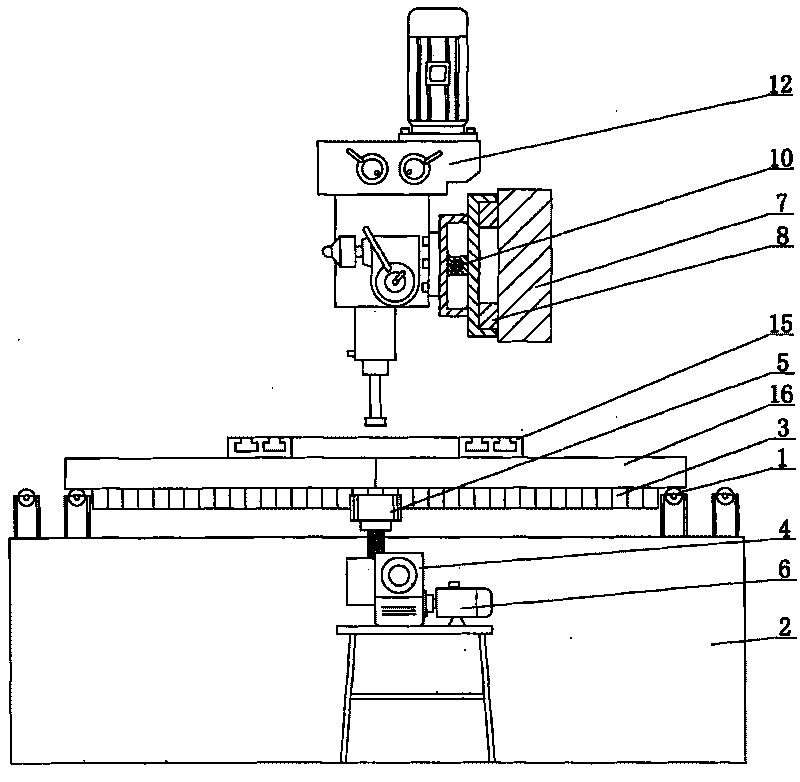

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] figure 1 , As shown in 2, the special milling machine for magnetic turning guide rails includes a workbench 16, a support carriage 2, a bearing box 13, a vertical milling head mechanism, and a workbench driving mechanism. The workbench 16 is fan-shaped or circular, and its center of circle is installed in the center of the bearing box 13, and the bottom surface of the arc edge is supported on the pulley 1 at the top of the supporting carriage 2; the vertical milling head mechanism includes a beam 7, a bracket 11, a vertical Milling head 12, guide rail 8, leading screw 10, scale 9, crossbeam 7 two ends are fixed on the support 11, crossbeam 7 one side is equipped with guide rail 8, leading screw 10, and vertical milling head 12 is installed on the guide rail 8; The workbench drive mechanism comprises a drive motor 6, a reduction box 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com