Equipment of induction type heating mould

An induction and mold technology, applied in the field of heating devices, can solve the problems of prolonged production cycle, many bonding lines on the product surface, and increased heating time of large molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

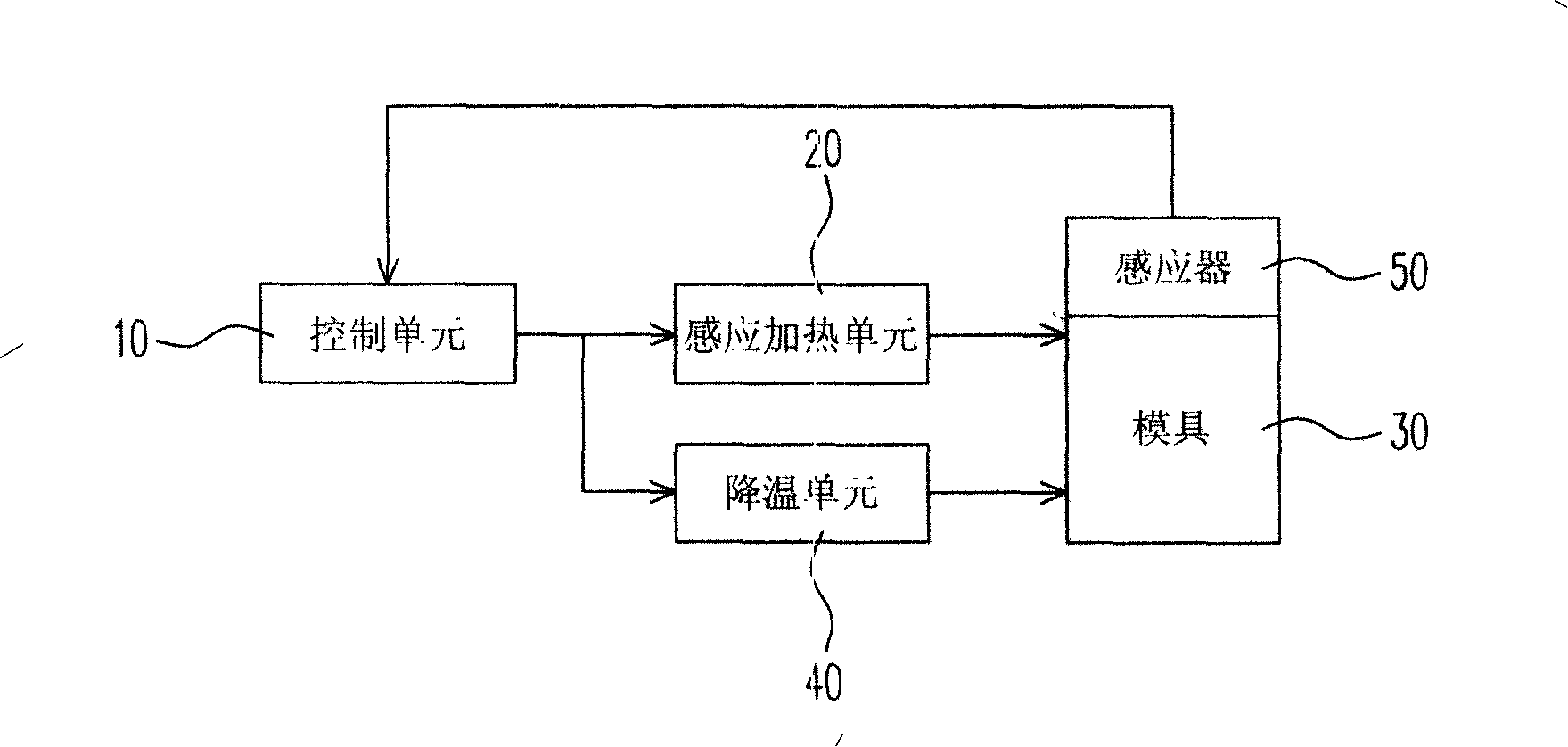

[0009] Please refer to figure 1 As shown, the present invention is an induction heating mold device, which is mainly applied to an injection molding machine. The heating device uses an induction heating unit 20 to heat a mold 30 .

[0010] The heating device mainly includes a control unit 10, an induction heating unit 20, a cooling unit 40, an openable and closable mold 30 and a temperature sensing unit arranged on the mold 30 (taking an inductor 50 as an example) .

[0011] Wherein, the sensor 50 is arranged on the mold 30 to detect the temperature of the mold 30, and sends a signal to the control unit 10, and the control unit 10 controls the induction heating unit 20 to the mold 30 after receiving the signal. After heating, the control unit 10 controls the cooling unit 40 to cool down the temperature of the mold 30 after the mold 30 is heated to a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com