Burning device for grain drier

A technology for burning equipment and grain, which is applied in the direction of burning equipment, burners for burning powder fuel, dryers, etc., and can solve problems such as increased oil price costs, increased drying costs, and lack of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Reference will now be made in detail to the preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings. The same reference symbols are used throughout to designate the same or similar parts.

[0020] Hereinafter, a combustion device for a grain dryer according to the present invention will be described in detail with reference to the accompanying drawings.

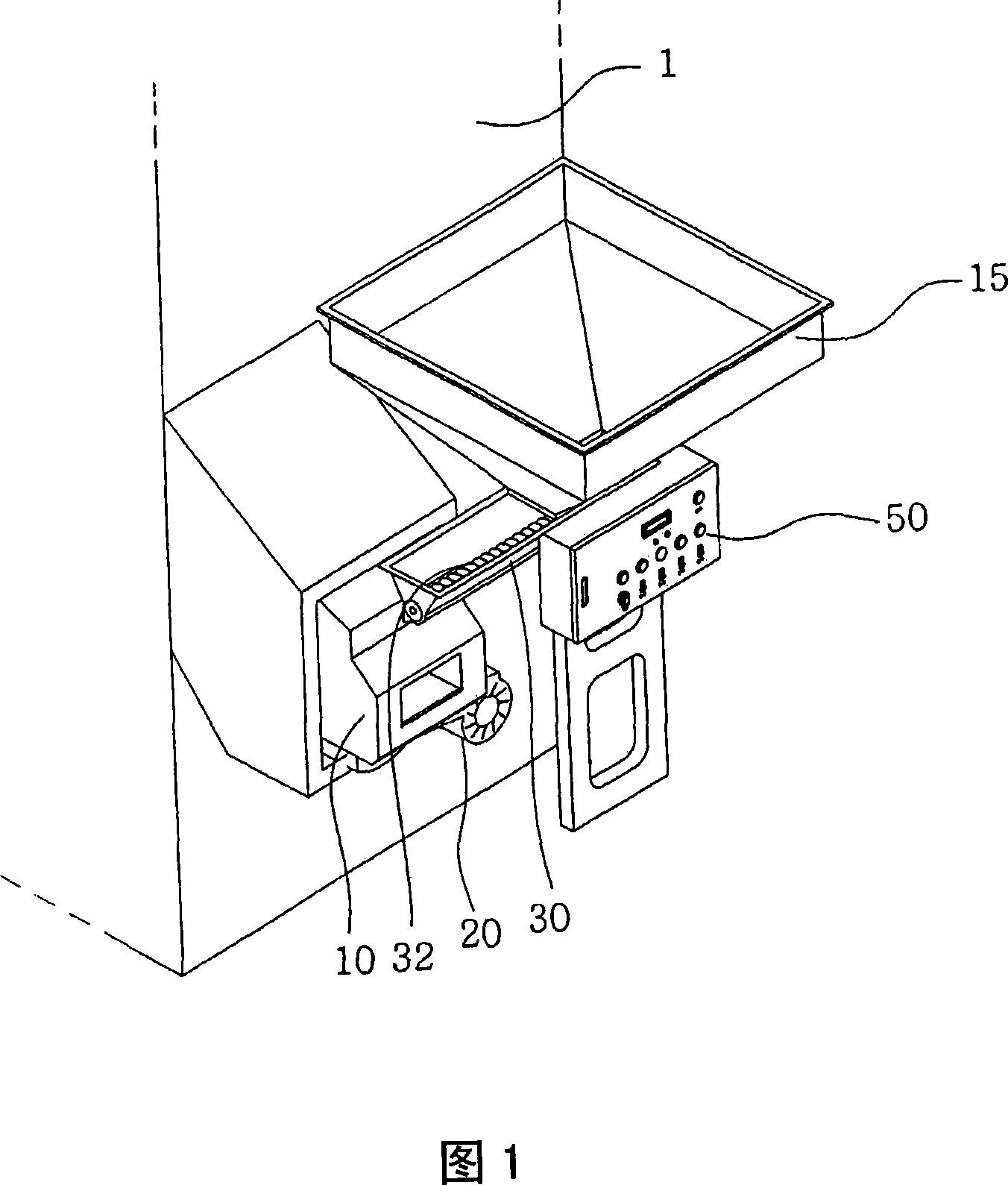

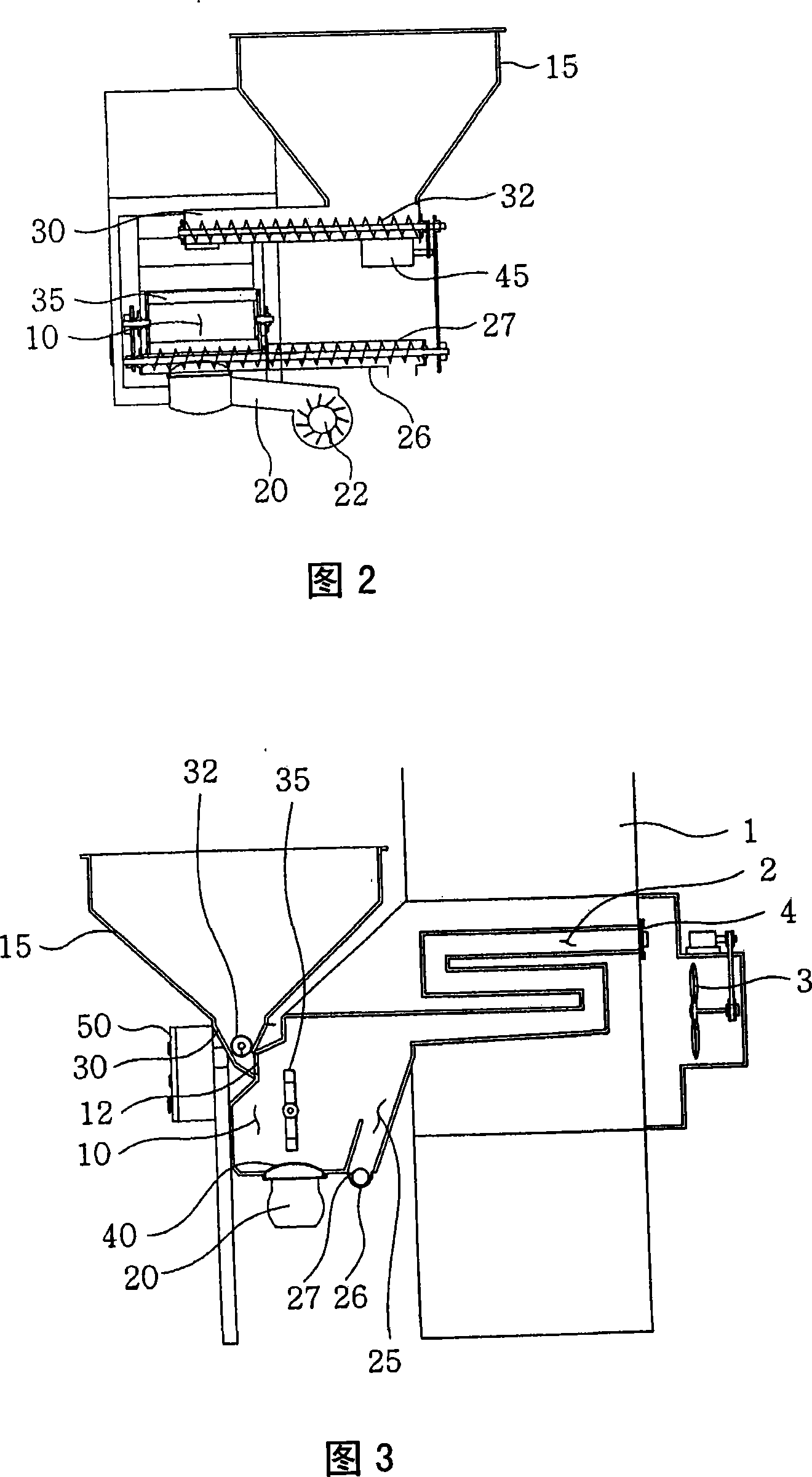

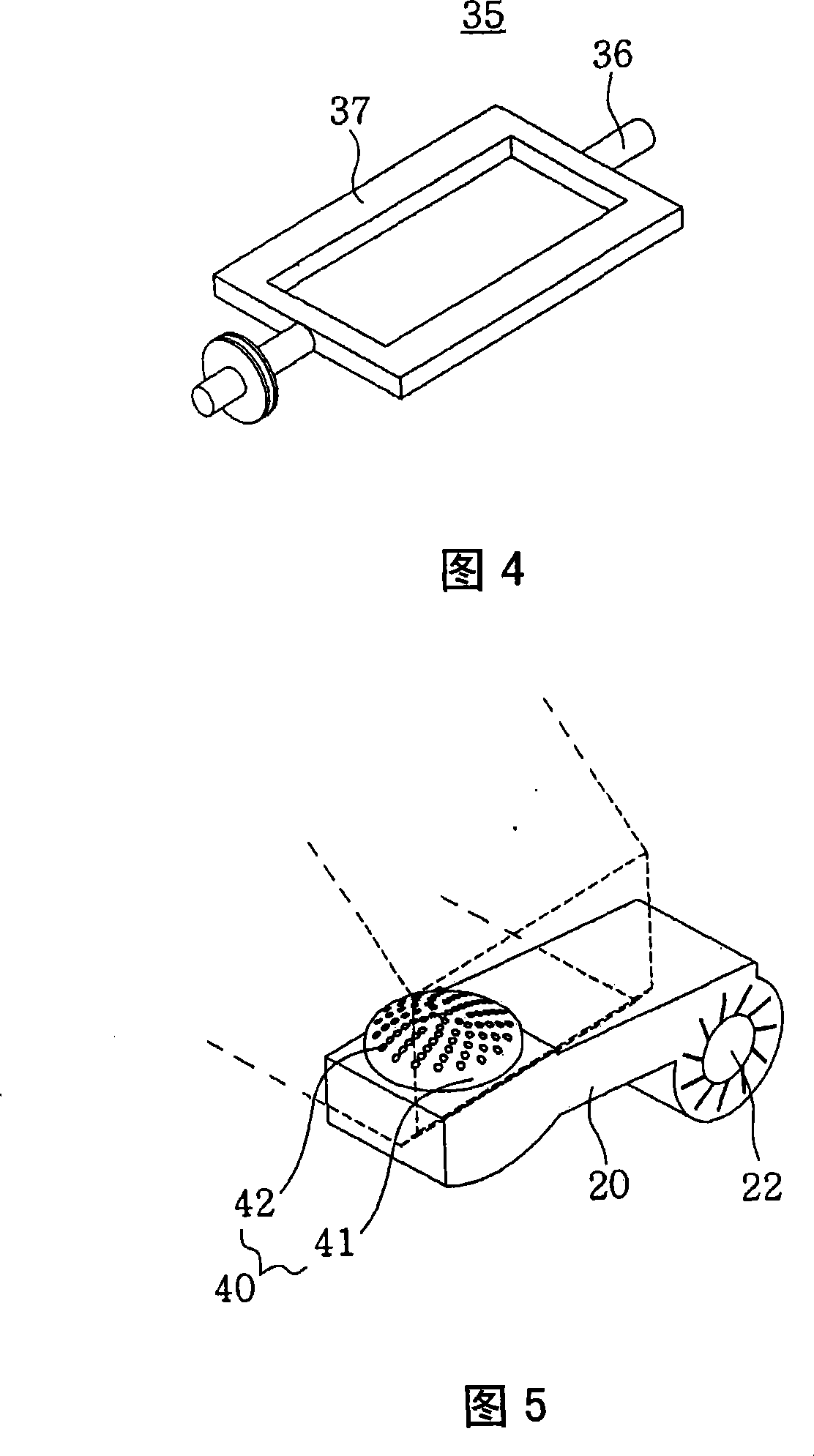

[0021] 1 is a perspective view illustrating a combustion device of a grain dryer according to the present invention, FIG. 2 is a cross-sectional view illustrating a combustion device of a grain dryer according to the present invention, and FIG. 3 is a diagram illustrating a combustion device of a grain dryer according to the present invention. 4 is a perspective view of a fuel distribution plate included inside a combustion chamber according to the present invention, and FIG. 5 is a perspective view of a combustion plate included inside a combustion chamber according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com