Apparatus and method for measuring microtubule gas-liquid diphasic flow rate

A flow rate measurement, capacitance technology, used in the field of metrology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

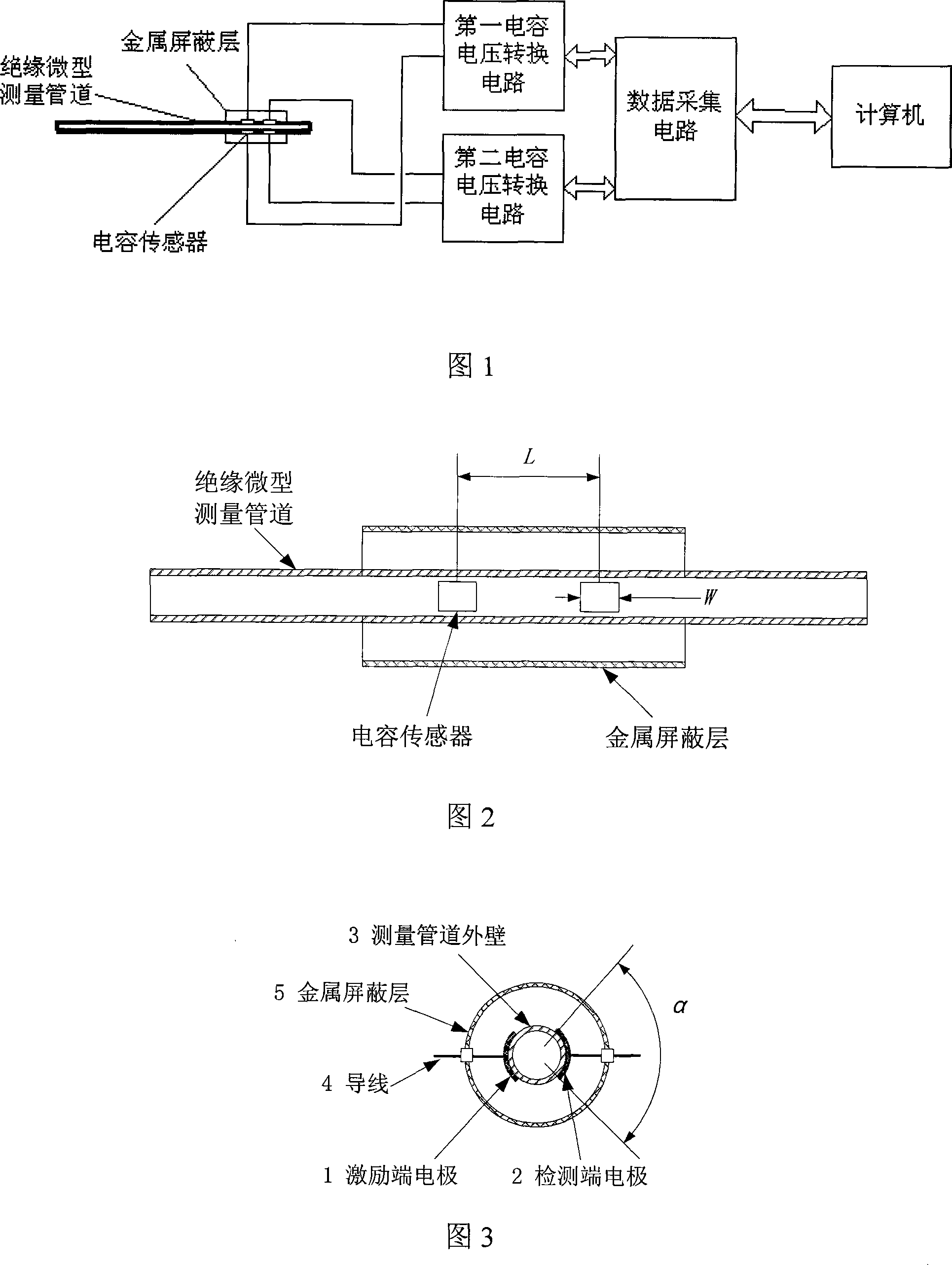

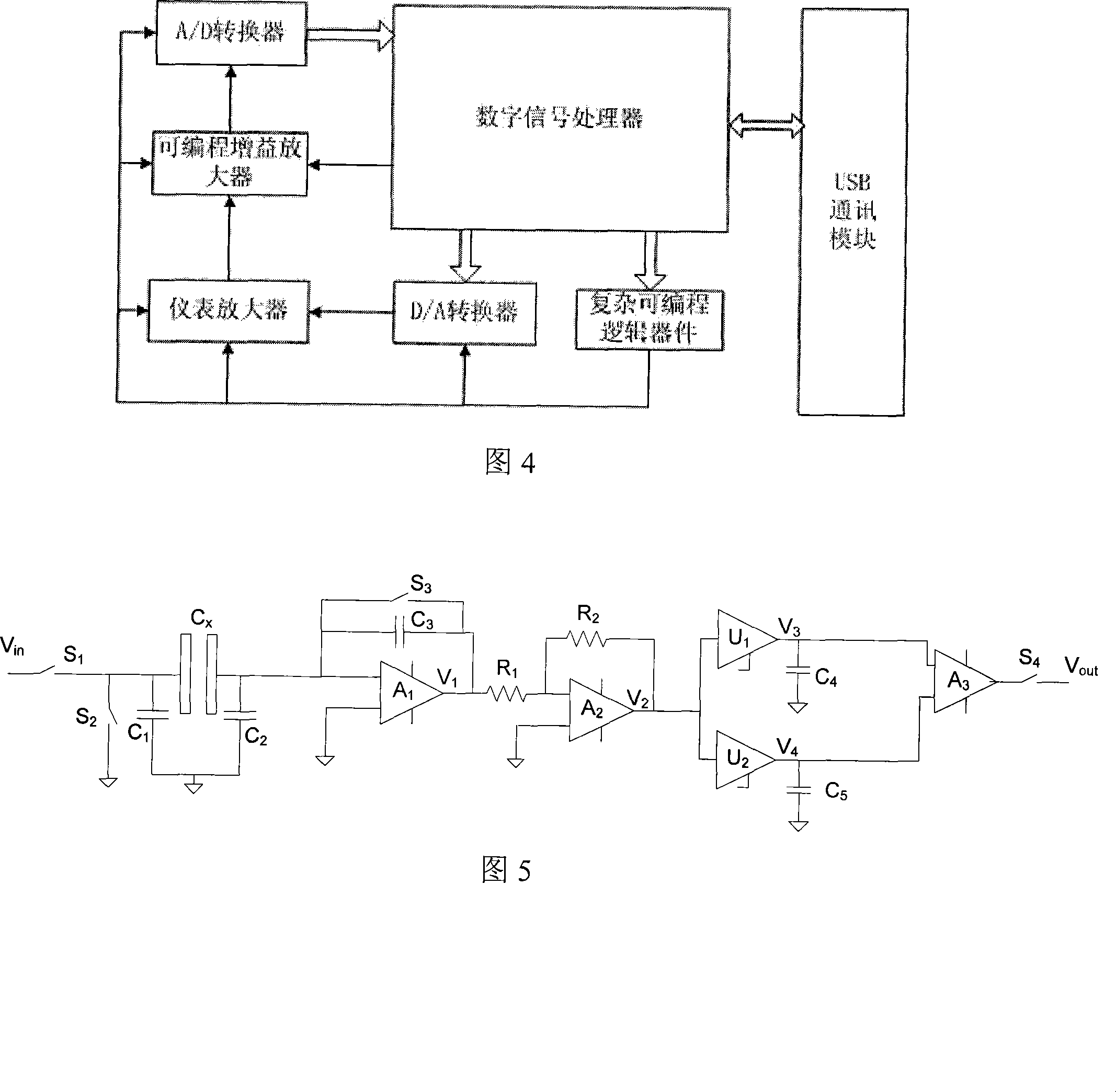

[0048] As shown in Figure 1, the microtube gas-liquid two-phase flow velocity measurement device based on the capacitance and cross-correlation method includes an insulated micro-measurement pipe with a diameter of millimeters, and two capacitive sensors with the same structure are installed on the periphery of the pipe. The capacitance sensor is connected with the first capacitance voltage conversion circuit and the second capacitance voltage conversion circuit respectively, and the capacitance voltage conversion circuit is connected with the computer through the data acquisition circuit. The capacitance sensor is composed of two symmetrical metal electrodes, which are respectively excitation terminal 1 and At the detection end 2, the two electrodes are symmetrical to each other and are installed close to the outer wall 3 of the insulated miniature measuring pipe, the electrodes are connected to the wire 4, and the outer side of the entire measuring pipe is evenly surrounded by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com