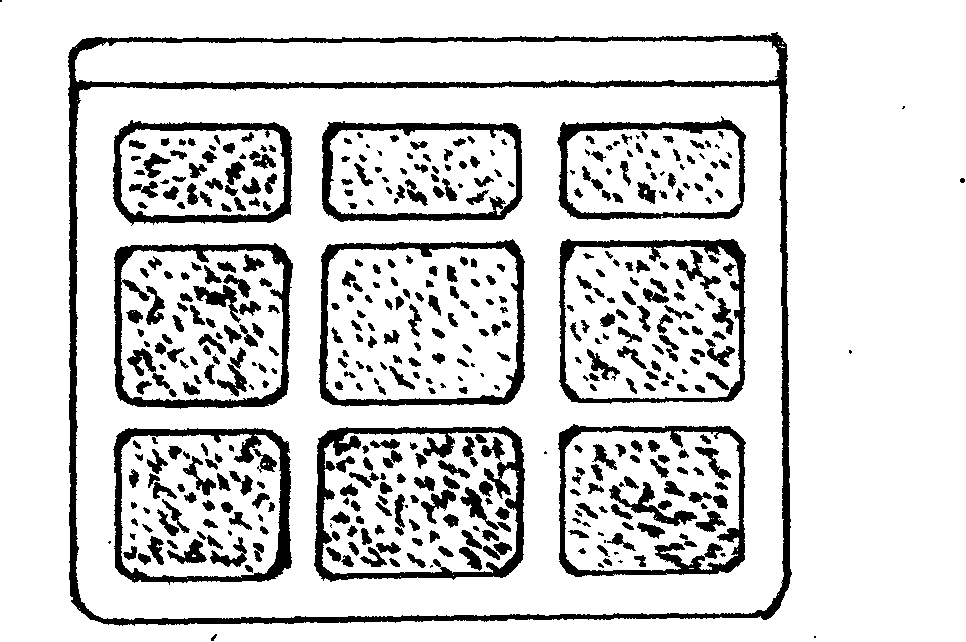

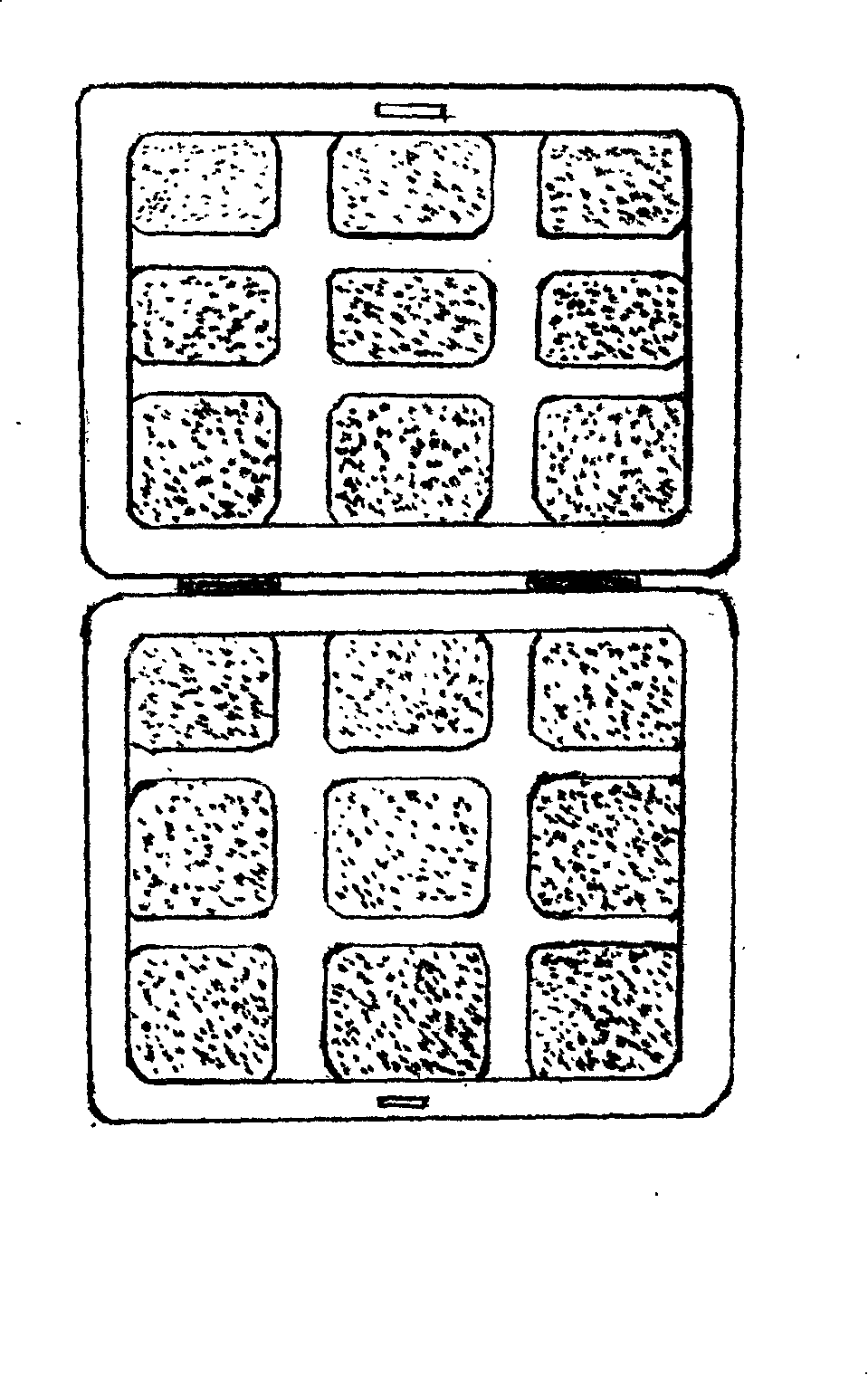

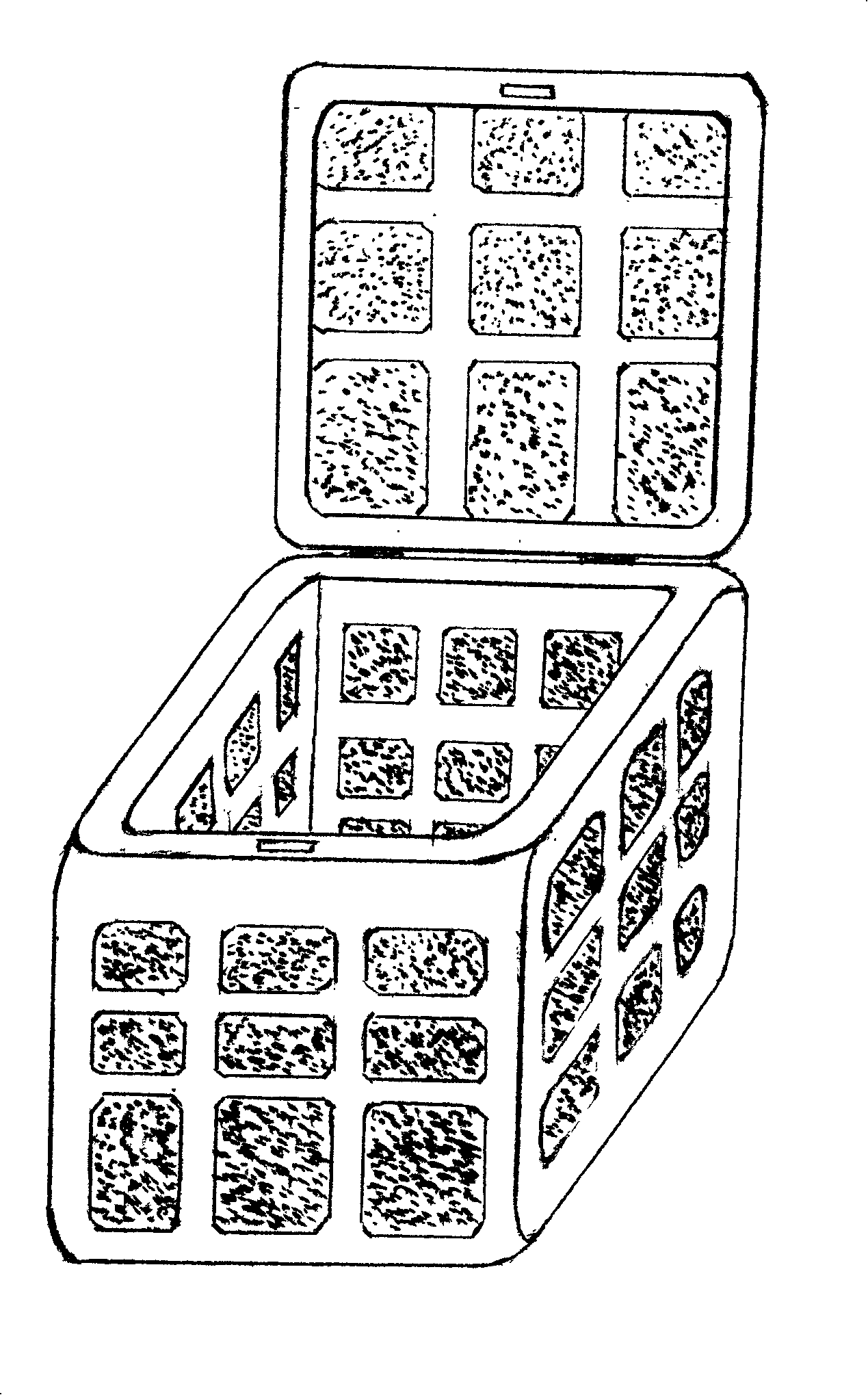

Soaking-drinking cage and preparation thereof

A cage-shaped, square-shaped technology, applied in the field of beverage brewing utensils, can solve the problems of inability to separate brewing materials and beverages, inconvenient portability, and inconvenient portability of new drinking tools, achieving low cost, easy selection, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] 1. Determine the size of the manufacturing drinking cage according to the specific individual requirements, and manufacture the mold for the upper cover and the lower cage that can be thermoplastically formed. The mold is a split structure.

[0014] 2. Choose recyclable polycarbonate materials that meet hygienic standards to make drinking cages, send them into corresponding injection molding machines, and control the temperature of the injection molding machines at 275°C to melt the above materials.

[0015] 3. A single-layer 80-mesh filter screen with a certain shape is pre-embedded in the corresponding position of the mold, and pushed into the setting station after the mold is closed.

[0016] 4. The polycarbonate material is injected into the mold, and the mold is shaped to form the reinforcement and the skeleton shape. Due to the hot-melt property of the polycarbonate material, the pre-embedded 80-mesh metal filter is wrapped and integrated by the polypropylene mater...

Embodiment 2

[0019] 1. According to the special use environment and requirements of traditional Chinese medicine decoction, determine the size of the manufacturing drinking cage, and manufacture the upper cover and the lower cage mold that can be thermoplastically formed. The mold is a split structure.

[0020] 2. Choose recyclable polyoxymethylene materials that meet hygienic standards to make drinking cages, send them into corresponding injection molding machines, and control the temperature of the injection molding machines at 380°C to melt the above materials.

[0021] 3. Five layers of filters with a certain shape are pre-embedded in the corresponding positions of the mold. Each layer is 20 mesh, 50 mesh, 120 mesh, 50 mesh, and 20 mesh. After the mold is closed, it is pushed into the setting station.

[0022] 4. The polyoxymethylene material is injected into the mold, and the mold is shaped to form the reinforcement and the skeleton shape. Due to the thermal melting property of the pol...

Embodiment 3

[0025] 1. According to the characteristics and dosage requirements of food spices, determine the size of the manufacturing drinking cage, and manufacture the mold for the upper cover and the lower cage that can be thermoformed. The mold is a split structure.

[0026] 2. Choose recyclable polypropylene materials that meet hygienic standards to make drinking cages, send them into corresponding injection molding machines, and control the temperature of the injection molding machines at 220°C to melt the above materials.

[0027] 3. A three-layer filter screen with a certain shape is embedded in the corresponding position of the mold in advance. Each layer is 40 mesh, 90 mesh, and 20 mesh respectively. After the mold is closed, it is pushed into the setting station.

[0028] 4. The polypropylene material is injected into the mould, and the mold is shaped to form the reinforcing rib and the skeleton shape. Due to the thermal melting property of the polypropylene material, the pre-em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com