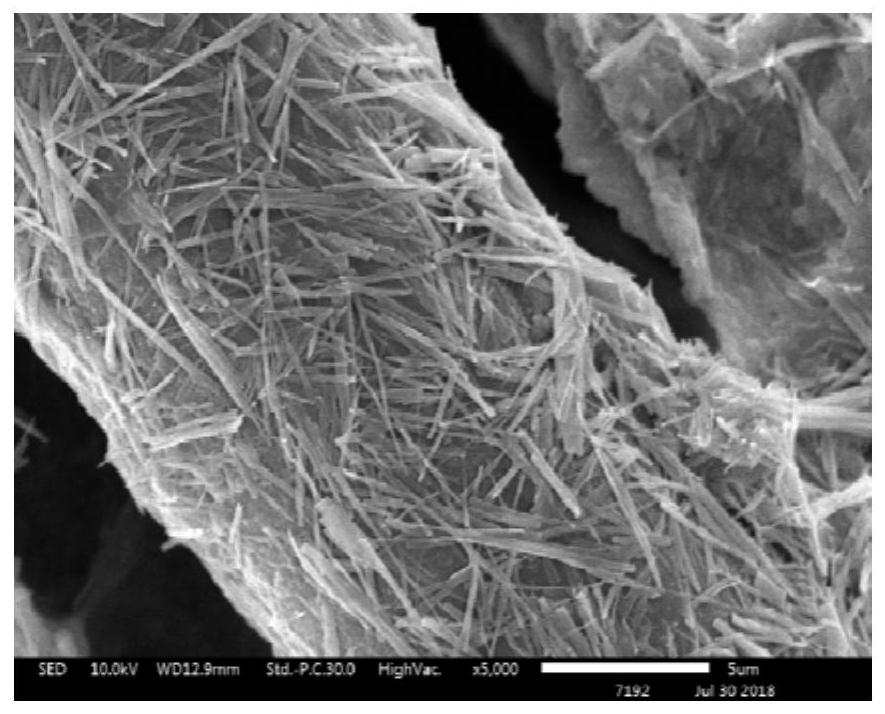

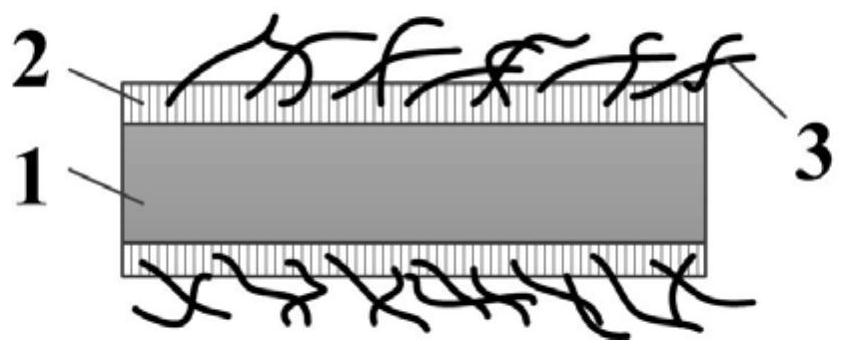

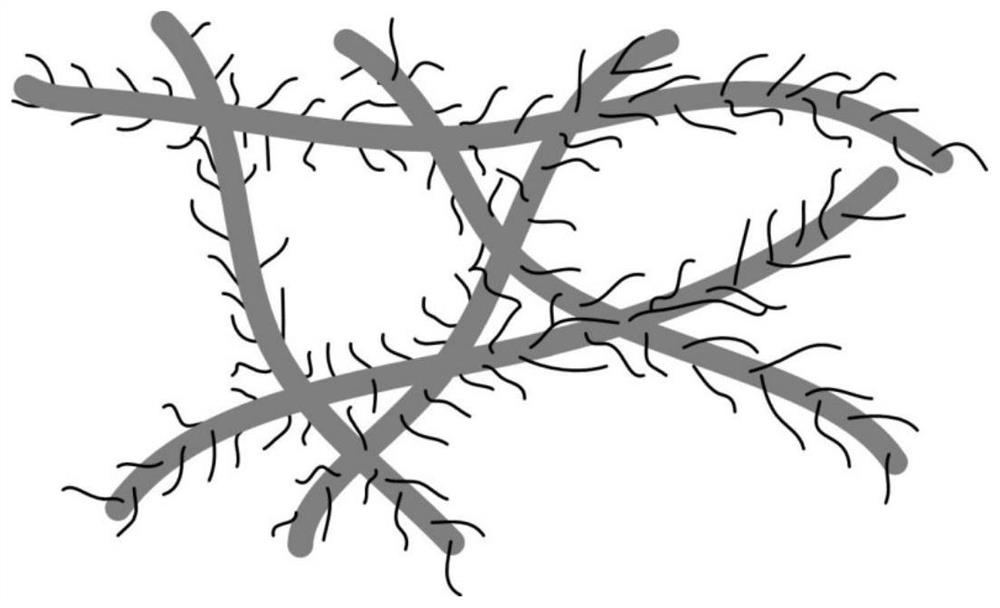

Nonwoven material composed of composite fibers with core-spun yarn structure and its preparation method

A technology of non-woven materials and composite fibers, which is applied in the field of fiber textile materials to achieve the effect of improving surface activity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Cut a piece of PP nonwoven fabric with a radius of 3 cm, and place it in a drying oven at 100° C. to dry. Prepare 100 mL of 1mol / L Tri-HCl buffer solution, then weigh 2g of PEI and add it to 1mol / L Tri-HCl buffer solution, stir to dissolve, and then adjust the pH value of the buffer solution to 8.5 with sodium hydroxide (NaOH) solution; Then take by weighing 3g of DOPA-HCl and add in the 1mol / L Tri-HCl buffer solution that is dissolved with PEI, stir and dissolve, promptly obtain containing PEI and Tri-HCl buffer solution; quickly transfer the prepared reaction system to a container with a PP nonwoven fabric with a radius of 3cm in advance, and react at 37°C for 24h; wash the reacted nonwoven material with water several times to obtain PDA / PEI-PP non-woven fabric, and sealed in the pure water system for use; Weigh 2mmol of Eu(NO 3 ) 3 ·6H 2 O was dissolved in 20 mL of ethanol and 10 mL of deionized water, and 1 mmol of trimesic acid was dissolved in 6 mL of ethanol...

Embodiment 2

[0039] Cut a piece of PP nonwoven fabric with a radius of 3 cm, and place it in a drying oven at 100° C. to dry. Prepare 200 mL of 1mol / L Tri-HCl buffer solution, then weigh 3g of PEI and add it to 1mol / L Tri-HCl buffer solution, stir to dissolve, and then adjust the pH value of the buffer solution to 8.5 with sodium hydroxide (NaOH) solution; Then take by weighing 3g of DOPA-HCl and add in the 1mol / L Tri-HCl buffer solution that is dissolved with PEI, stir and dissolve, promptly obtain containing PEI and Tri-HCl buffer solution; quickly transfer the prepared reaction system to a pre-prepared container of PP nonwoven fabric with a radius of 3cm, shake and react at 37°C for 24h; wash the reacted nonwoven material several times with water to obtain PDA / PEI-PP nonwoven fabric, and sealed in pure water system for use; weigh 2mmol of Eu(NO 3 ) 3 ·6H 2 O was dissolved in 20mL of ethanol and 10mL of deionized water, weighed 1mmol of trimesic acid and dissolved in 6mL of ethanol a...

Embodiment 3

[0041] Cut a piece of PP nonwoven fabric with a radius of 3 cm, and place it in a drying oven at 100° C. to dry. Prepare 300 mL of 1mol / L Tri-HCl buffer solution, then weigh 4g of PEI and add it to 1mol / L Tri-HCl buffer solution, stir to dissolve, and then adjust the pH value of the buffer solution to 8.5 with sodium hydroxide (NaOH) solution; Then take by weighing 3g of DOPA-HCl and add in the 1mol / L Tri-HCl buffer solution that is dissolved with PEI, stir and dissolve, promptly obtain containing PEI and Tri-HCl buffer solution; quickly transfer the prepared reaction system to a pre-prepared container of PP nonwoven fabric with a radius of 3cm, shake and react at 37°C for 24h; wash the reacted nonwoven material several times with water to obtain PDA / PEI-PP nonwoven fabric, and sealed in pure water system for use; weigh 2mmol of Eu(NO 3 ) 3 ·6H 2 O was dissolved in 20mL of ethanol and 10mL of deionized water, weighed 1mmol of trimesic acid and dissolved in 6mL of ethanol a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com