Composite electrochemical electrode and preparation method thereof

An electrochemical and electrode technology, applied in the field of electrochemistry, can solve problems such as poor electrical conductivity, poor filtration performance, and difficult membrane pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

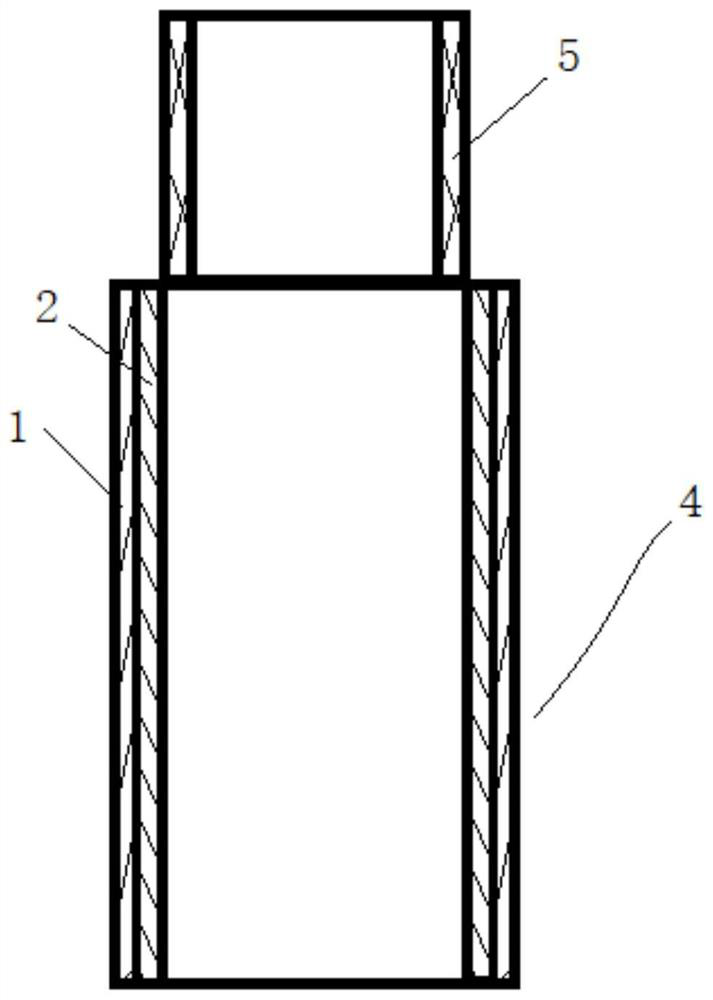

[0081] The supporting body for preparing the composite electrochemical electrode in the specific embodiment of the present invention is illustrated by taking the hollow tubular inorganic ceramic membrane as an example, and other tubular or other hollow ceramic membranes of any shape are suitable for the supporting matrix of the composite electrochemical electrode of the present invention ; The composite modification layer on the surface of the composite electrochemical electrode selects 304 stainless steel mesh as an example for illustration, and other wire meshes made of wires made of conductive metals, such as iron wires, aluminum wires, copper wires, etc. In the modified composite layer of the composite electrochemical electrode of the present invention.

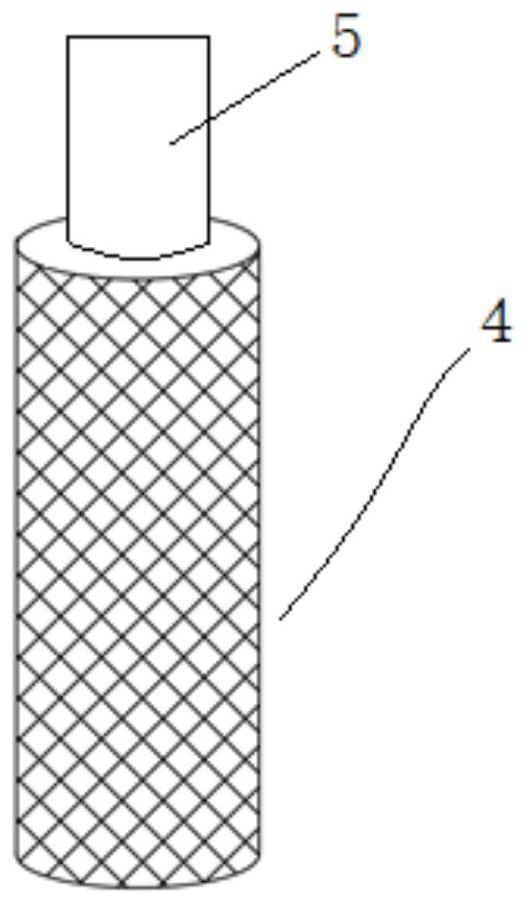

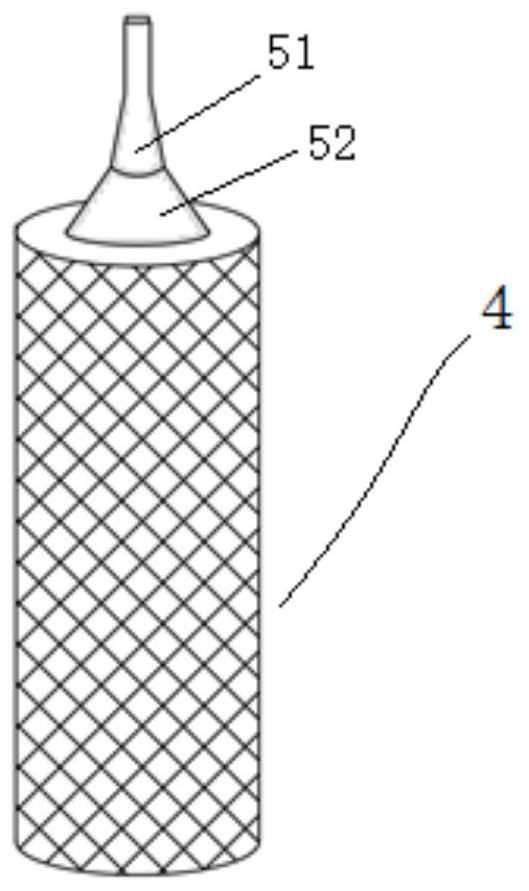

[0082] Such as figure 1 , 2 As shown, the composite electrochemical electrode 4 of the present invention includes an electrode matrix hollow ceramic membrane 2, a wire mesh modification layer that matches the size of the...

Embodiment 1

[0092] Embodiment 1 prepares composite electrochemical electrode

[0093] Such as image 3 , is the flow chart of the preparation of the composite electrochemical electrode of the present invention.

[0094] 1. Pretreatment of ceramic membrane

[0095] 1A. Place the hollow ceramic membrane in lye, soak it for 16h (usually 10-20h), and carry out alkali cleaning treatment on the ceramic membrane to remove oil stains and iron oxide chips on the surface of the wire mesh, wherein the lye is selected at a mass percentage of 10 % (usually 10-15%) NaOH solution, then take it out and rinse it with water until the cleaning solution is neutral;

[0096] The lye in the embodiment of the present invention is illustrated by taking sodium hydroxide solution as an example, and other lye such as potassium hydroxide and calcium hydroxide solutions are applicable to the present invention.

[0097] 1B. Soak the ceramic membrane after alkaline cleaning in 25% ethanol solution by volume (usually...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com