Method for testing water white resistance of real stone paint

A real stone paint, performance technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

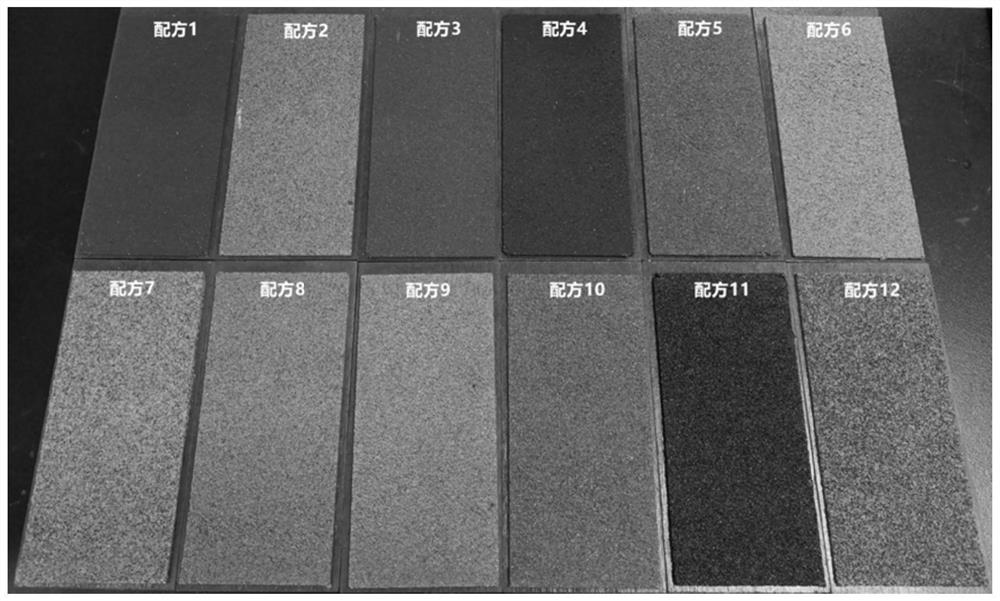

[0048] Embodiment 1 (low temperature and low humidity blast curing-soaking in water-standard environment drying)

[0049] The test method for water whitening resistance of real stone paint under this condition includes the following steps:

[0050] (1) Paint mixing: first calculate the amount according to the total amount of required paint of 300g and the composition and ratio of the colored sand in formula 1, and then weigh the various sand materials with a total amount of N into the 250ml sample tank A in turn, Shake with a shaker for 5 minutes to disperse evenly, then calculate the dosage according to the total amount of 2*(300-N) and the ratio of slurry (excluding emulsion) and emulsion in formula 1, then weigh and pour into sample tank B In the process, use a high-speed disperser to stir evenly at a speed of 400-800r / min (need to prepare too much) to prepare a mixed slurry (containing emulsion), and finally weigh the mixed slurry (300-N) from the sample tank B and pour P...

Embodiment 2

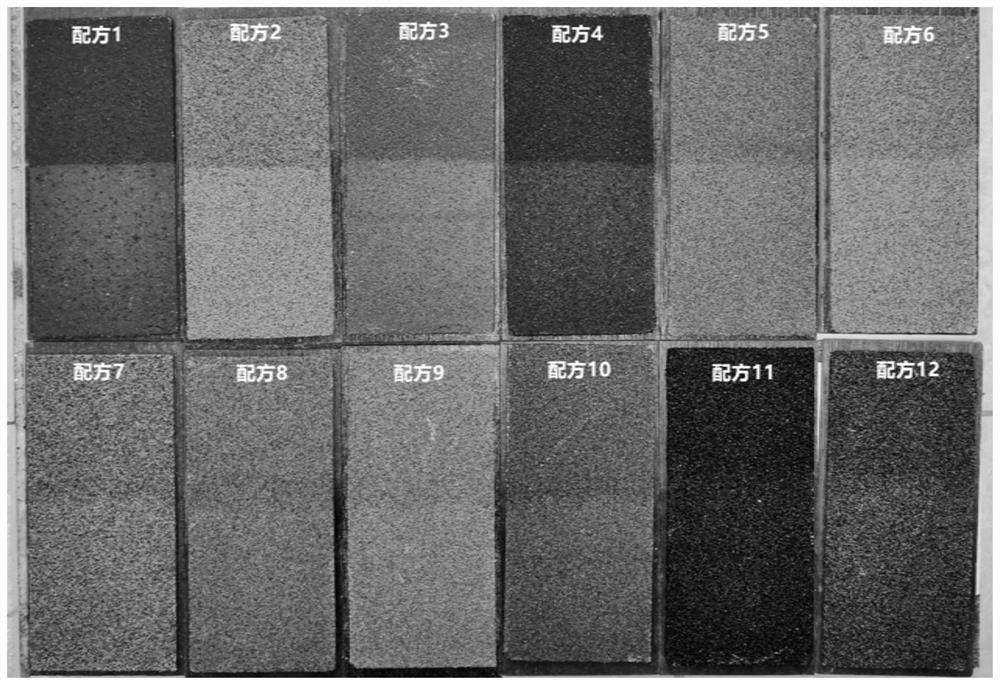

[0062] Embodiment 2 (low temperature and low humidity blast curing-soaking in water-low temperature and low humidity blast drying)

[0063] The test method for water whitening resistance of real stone paint under this condition includes the following steps:

[0064] (1) Paint mixing: In order to make the conditions of the paint samples consistent, 12 paint samples (formula 1-12) prepared in Example 1 were used for testing.

[0065] (2) Substrate treatment: Take 12 asbestos-free fiber cement pressurized boards with a specification of 150*70*6mm, paint a colorless and transparent primer on the upper surface with a brush, and dry for more than 2 hours for later use;

[0066] (3) Plate making: Take a steel frame with an inner frame size of 140*65mm, an outer frame size of 200*125mm and a thickness of 2mm on the asbestos-free fiber cement pressure plate, align the corners, and then use a 5-inch Scrape the paint samples of formula 1-12 on 12 asbestos-free fiber cement pressure plat...

Embodiment 3

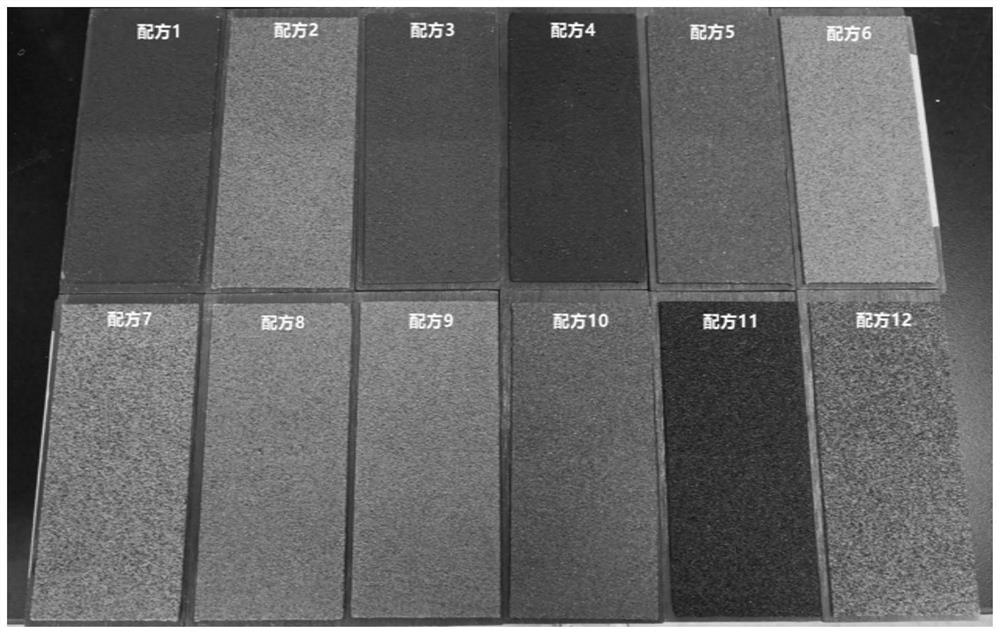

[0075] Embodiment 3 (standard environmental maintenance-soaking in water-low temperature and low humidity blast drying)

[0076] The test method for water whitening resistance of real stone paint under this condition includes the following steps:

[0077] (1) paint distribution: in order to make the paint sample condition consistent, use 12 paint samples (prescription 1-12) prepared by embodiment 1 to test;

[0078] (2) Substrate treatment: Take 12 asbestos-free fiber cement pressurized boards with a specification of 150*70*6mm, paint a colorless and transparent primer on the upper surface with a brush, and dry for more than 2 hours for later use;

[0079] (3) Plate making: Take a steel frame with an inner frame size of 140*65mm, an outer frame size of 200*125mm and a thickness of 2mm on the asbestos-free fiber cement pressure plate, align the corners, and then use a 5-inch Scrape the paint samples of formula 1-12 on 12 asbestos-free fiber cement pressure plates in batches al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com