Aluminum alloy die-casting waste gas treatment device

A waste gas treatment device, aluminum alloy technology, applied in the separation of dispersed particles, chemical instruments and methods, filtration of dispersed particles, etc., can solve the problems of atmospheric pollution, high temperature, damage to the surrounding environment, etc. , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

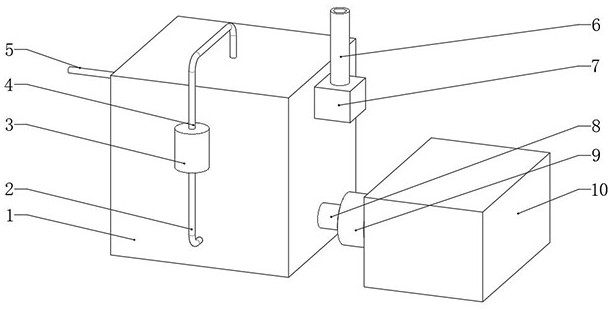

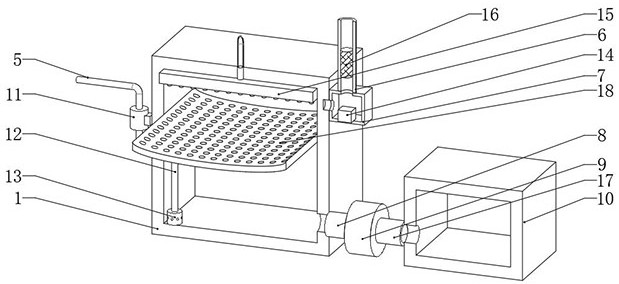

[0027] refer to Figure 1-2 , an aluminum alloy die-casting exhaust gas treatment device, comprising a box body 1 and a liquid replenishment box 10, filter plates 18 are fixed to the inner walls of both sides of the box body 1 by screws, and the top outer wall of the filter plate 18 is provided with equidistantly distributed air outlets, One side of the outer wall of the box body 1 is provided with a first round hole, and the inner wall of the first round hole is fixed with a water inlet pipe 12, and the bottom outer wall of the water inlet pipe 12 is inserted with a bubble tank 13, and the outer wall around the bubble tank 13 is opened. There are air bubbles distributed equidistantly.

[0028] In the present invention, an air suction pump 11 is fixed on one side of the outer wall of the box body 1 by screws, and the output end of the air suction pump 11 is plugged with the water inlet pipe 12, and the input end of the box body 1 is plugged with an air intake pipe 5, and the b...

Embodiment 2

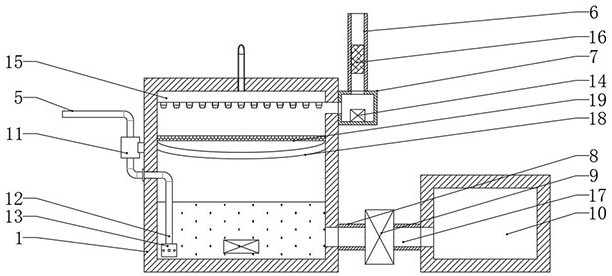

[0031] refer to image 3 , an aluminum alloy die-casting exhaust gas treatment device. Compared with Embodiment 1, this embodiment also includes a honeycomb sponge board 19 fixed on both sides of the inner wall of the box body 1 by screws, and the honeycomb sponge board 19 is located between the atomizing nozzle and the filter plate Between 18.

[0032] Working principle: The atomizing nozzle atomizes the reaction liquid, which can wet the honeycomb sponge board 19, and the exhaust gas will contact the honeycomb sponge board 19. The honeycomb sponge board 19 has a honeycomb structure that can slow down the flow speed of the gas, and at the same time increase the contact with the gas. Contact area, that is, increase the contact area between the reaction liquid and the exhaust gas, and improve the treatment efficiency of the exhaust gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com