Direct-feeding type waste plastic asphalt modifier and preparation method thereof

A kind of asphalt modifier, technology of waste plastics, applied in the field of direct throwing waste plastic asphalt modifier and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

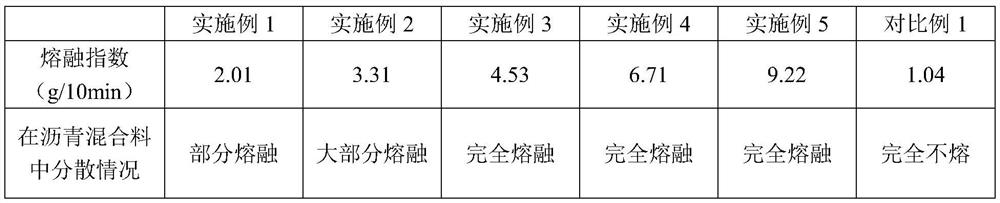

Embodiment 1

[0030] The invention discloses a preparation method of a direct throw-in waste plastic asphalt modifier, which comprises the following steps:

[0031] (1) 89 parts of LDPE recycled materials, 10 parts of high fluidity low-density polyethylene and 1 part of antioxidant are mixed in a high-speed mixer according to the ratio of parts by mass, and the blended material is obtained after stirring;

[0032] The working parameters of the high-speed mixer are 500rpm, the mixing time is 5min, and the mixing temperature is below 60°C.

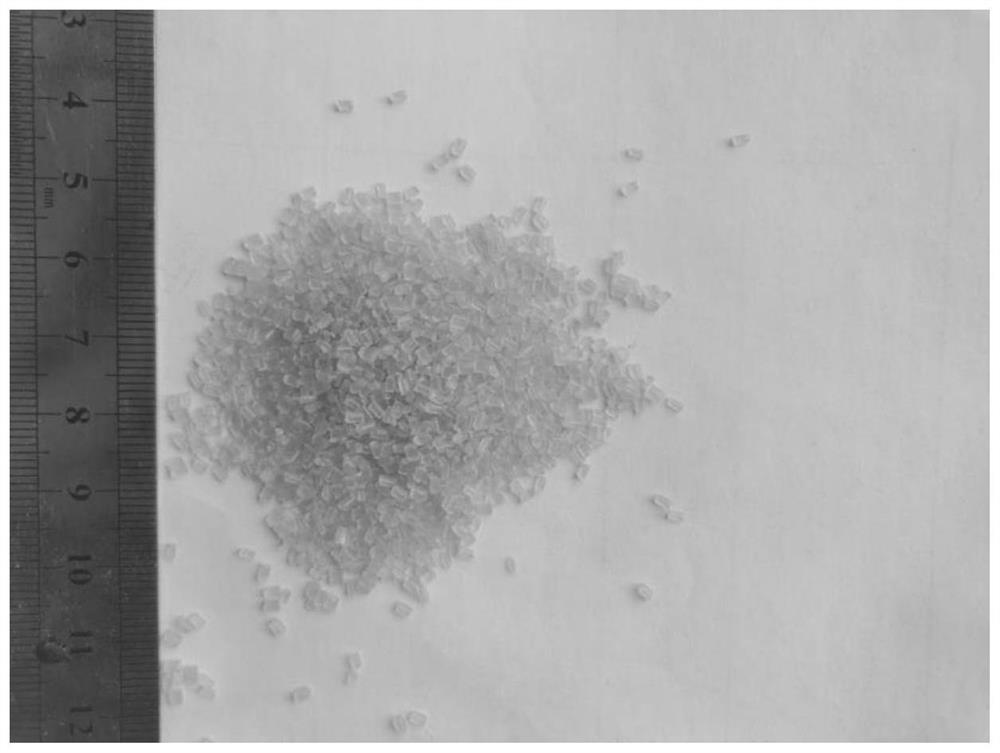

[0033] (2) Putting the blended material into a twin-screw extruder to extrude and granulate to obtain a direct-input type waste plastic asphalt modifier.

Embodiment 2

[0035] The invention discloses a preparation method of a direct throw-in waste plastic asphalt modifier, which comprises the following steps:

[0036] (1) 79 parts of LDPE recycled materials, 20 parts of high fluidity low-density polyethylene and 1 part of antioxidant are mixed in a high-speed mixer according to the ratio of parts by mass, and the blended material is obtained after stirring;

[0037]The working parameters of the high-speed mixer are 500rpm, the mixing time is 5min, and the mixing temperature is below 60°C.

[0038] (2) Putting the blended material into a twin-screw extruder to extrude and granulate to obtain a direct-input type waste plastic asphalt modifier.

Embodiment 3

[0040] The invention discloses a preparation method of a direct throw-in waste plastic asphalt modifier, which comprises the following steps:

[0041] (1) 69 parts of LDPE recycled materials, 30 parts of high-fluidity low-density polyethylene and 1 part of antioxidant are mixed in a high-speed mixer according to the ratio of parts by mass, and the blended material is obtained after stirring;

[0042] The working parameters of the high-speed mixer are 500rpm, the mixing time is 5min, and the mixing temperature is below 60°C.

[0043] (2) Putting the blended material into a twin-screw extruder to extrude and granulate to obtain a direct-input type waste plastic asphalt modifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com