Photosensitive insulated resin composition and method of producing insulated film thereof

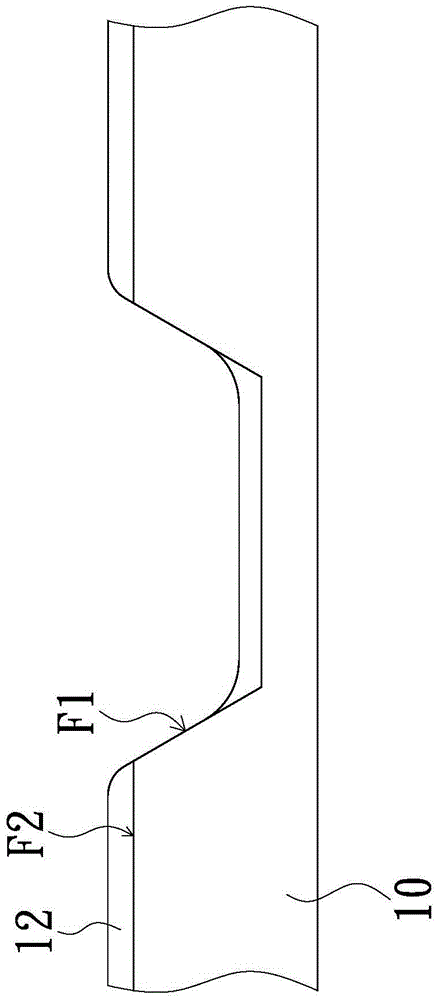

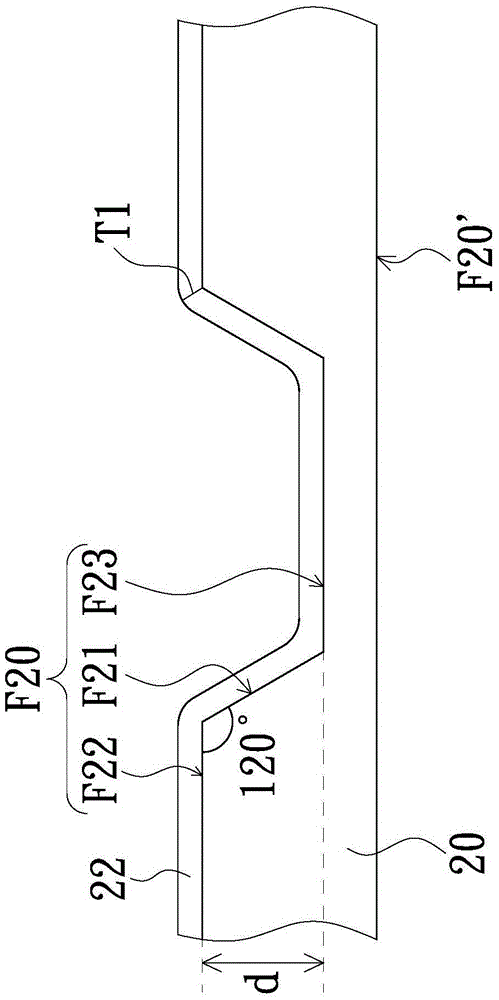

An insulating resin, photosensitivity technology, applied in the photoengraving process of the pattern surface, photosensitive materials for opto-mechanical equipment, optics, etc. problems, to achieve excellent resolution and insulation, to avoid uneven coverage thickness, and it is difficult for the film to flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

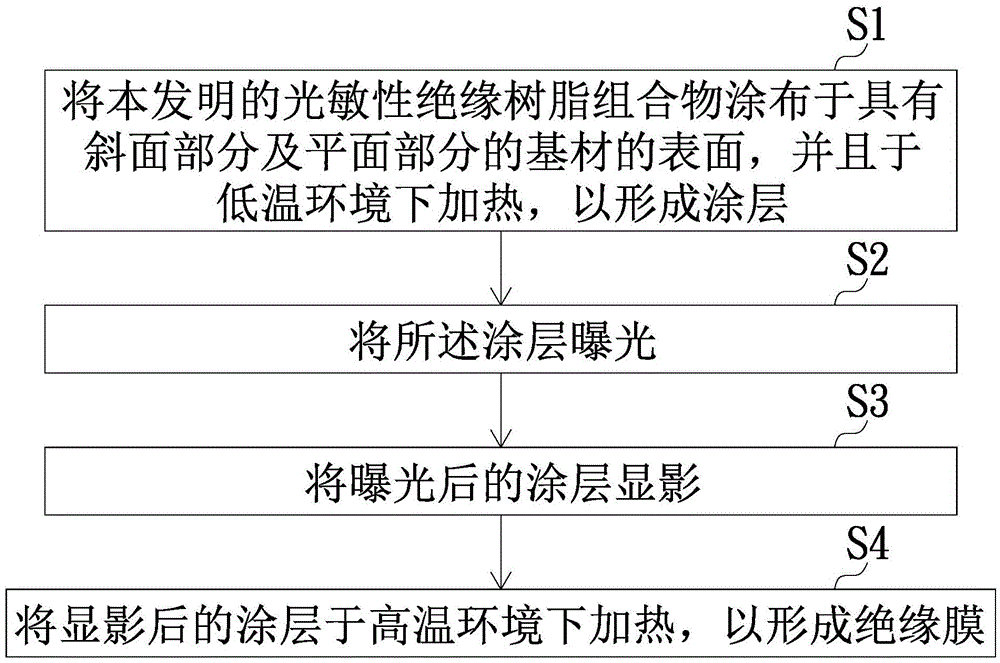

Method used

Image

Examples

no. 1 example

[0063] According to the first embodiment of the present invention, the photosensitive insulating resin composition comprises component (A1) phenolic resin (the molar ratio of m-cresol and p-cresol is 5:5, Mw: 8000) 100 parts by mass; ( B1) 4,4'-[1-[4-[1-(4-hydroxyphenyl)-1-methylethyl]phenyl]ethylene]bis(phenol) and 1,2-naphthoquinone 30 parts by mass of azido-5-sulfonic acid condensate; (C1) 20 parts by mass of hexamethoxymethylmelamine; (E1) 0.05 parts by mass of fluorine-containing surfactant (model: F-554, manufactured by DIC); (D1) 900 parts by mass of acetone and (D2) 120 parts by mass of propylene glycol monomethyl ether acetate. Dissolving (A1), (B1), (C1), and (E1) in (D1) and (D2) (the sequence is not limited) to prepare a photosensitive insulating resin composition.

[0064]According to the second embodiment of the present invention, the photosensitive insulating resin composition comprises component (A2) phenolic resin (the molar ratio of m-cresol and p-cresol is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com