Phosphorus-removal and antibacterial nanometer fiber membrane and preparing method thereof

A nanofiber membrane, nanotechnology, applied in fiber processing, non-woven fabrics, textiles and papermaking, etc., can solve the problems of complex processing technology, achieve the effect of simple processing technology, simplified water purification process, and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

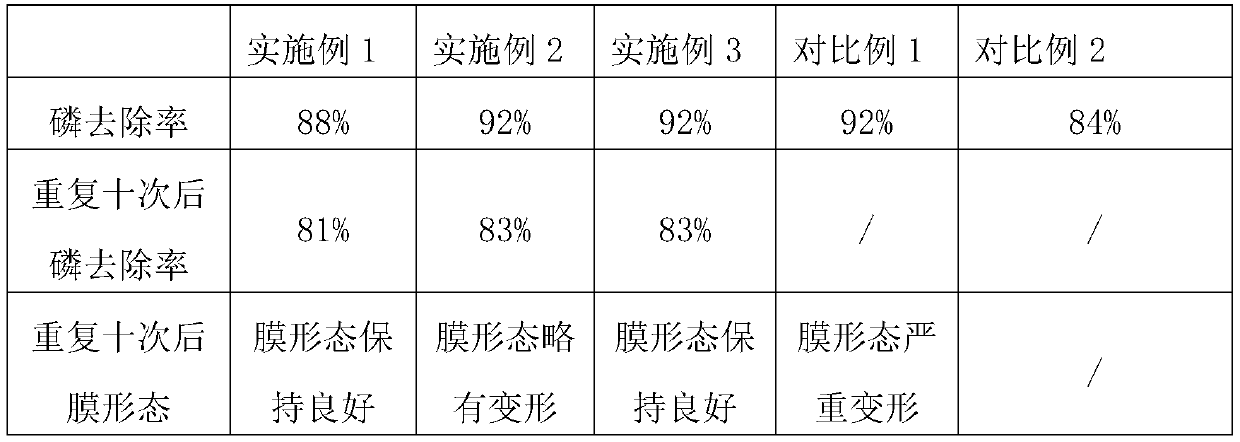

Examples

Embodiment 1

[0024] In step a, select a commercially available nano-layered silicate product, sodium montmorillonite-Laponite RD, and activate it by cationic modification. Add 10g of Laponite RD into 100g of deionized water, mix to form a uniform slurry, add 0.2g of hexadecylpyridinium chloride at 80°C, stir and react for 120min, filter the slurry with suction, wash and dry to obtain organic modified The nano-phosphorus adsorbent A. A is configured as tetrahydrofuran dilution B with a mass fraction of 10%.

[0025] Step b. Take 10 g of polyacrylonitrile, dissolve it in N-methylformamide (DMF), and prepare a solution C with a mass fraction of 8% for future use.

[0026] Step c, take 2.5g of diluent B and 62.5g of solution C, and mix the two evenly to obtain spinning solution D. The D solution is injected into the syringe in the high-voltage electrospinning device, and a metal needle is assembled on the syringe, and the metal needle is connected to one pole of the high-voltage power supply...

Embodiment 2

[0030] In step a, select a commercially available nano-layered silicate product, sodium montmorillonite-Laponite RD, and activate it by cationic modification. Add 10g of Laponite RD into 100g of deionized water, mix to form a uniform slurry, add 0.2g of hexadecylpyridinium chloride at 80°C, stir and react for 120min, filter the slurry with suction, wash and dry to obtain organic modified The nano-phosphorus adsorbent A. A is configured as tetrahydrofuran dilution B with a mass fraction of 10%.

[0031] Step b. Take 10 g of polyacrylonitrile, dissolve it in N-methylformamide (DMF), and prepare a solution C with a mass fraction of 8% for future use.

[0032] Step c, take 10g of diluent B and 62.5g of solution C, and mix the two evenly to obtain spinning solution D. The D solution is injected into the syringe in the high-voltage electrospinning device, and a metal needle is assembled on the syringe, and the metal needle is connected to one pole of the high-voltage power supply....

Embodiment 3

[0036] In step a, select a commercially available nano-layered silicate product, sodium montmorillonite-Laponite RD, and activate it by cationic modification. Add 10g of Laponite RD into 100g of deionized water, mix to form a uniform slurry, add 0.2g of hexadecylpyridinium chloride at 80°C, stir and react for 120min, filter the slurry with suction, wash and dry to obtain organic modified The nano-phosphorus adsorbent A. A is configured as tetrahydrofuran dilution B with a mass fraction of 10%.

[0037] Step b. Take 10 g of polyacrylonitrile, dissolve it in N-methylformamide (DMF), and prepare a solution C with a mass fraction of 8% for future use.

[0038] Step c, take 5g of diluent B and 62.5g of solution C, and mix the two evenly to obtain spinning solution D. The D solution is injected into the syringe in the high-voltage electrospinning device, and a metal needle is assembled on the syringe, and the metal needle is connected to one pole of the high-voltage power supply. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com