Hexa-claw executing mechanism of weeding robot

A technology of an actuator and a robot, applied in the field of agricultural robots, can solve problems such as the inability to meet the needs of weeding and the inability to realize integrated weeding, and achieve the effects of continuous weeding action, small overall size, and simple and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

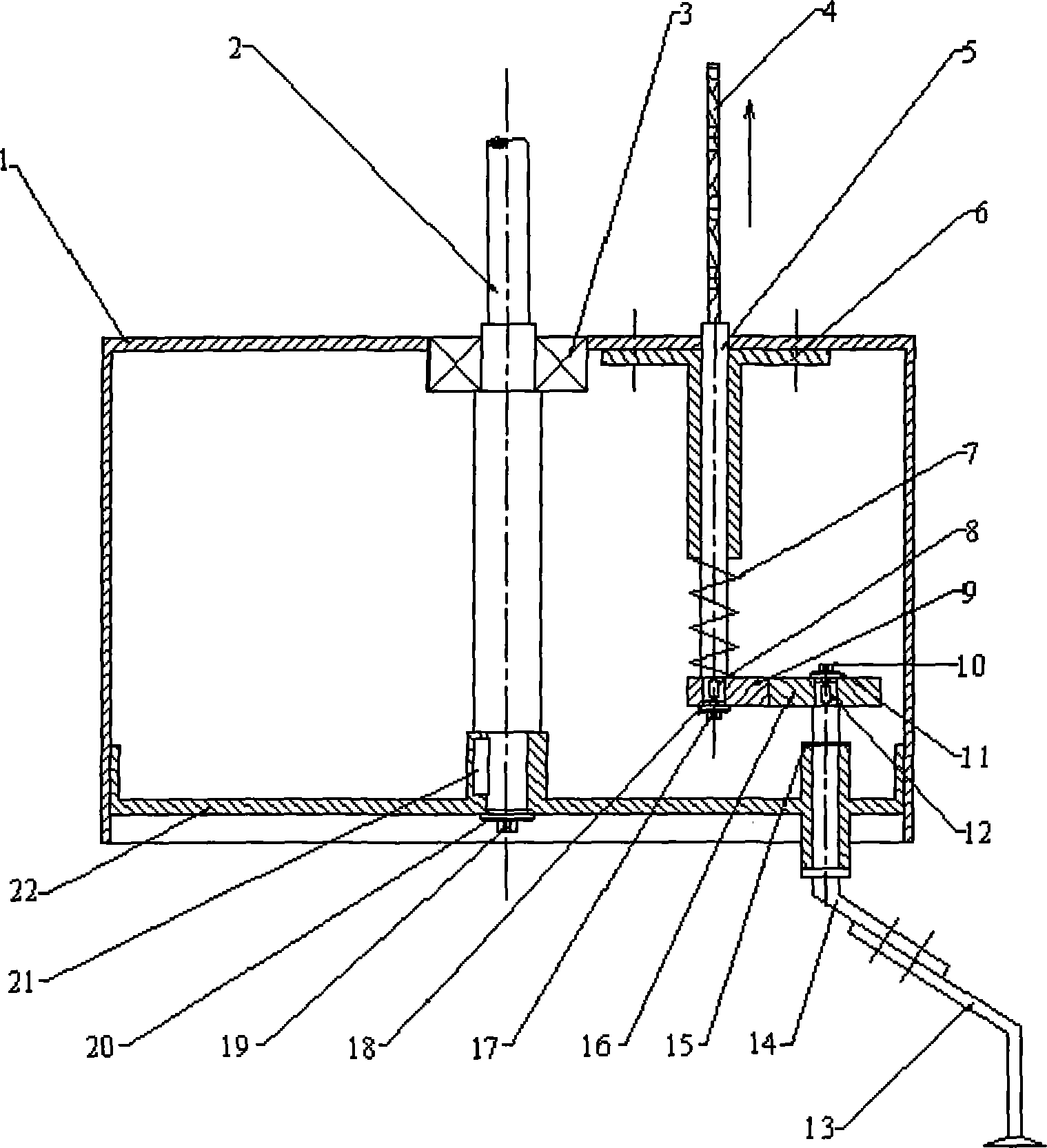

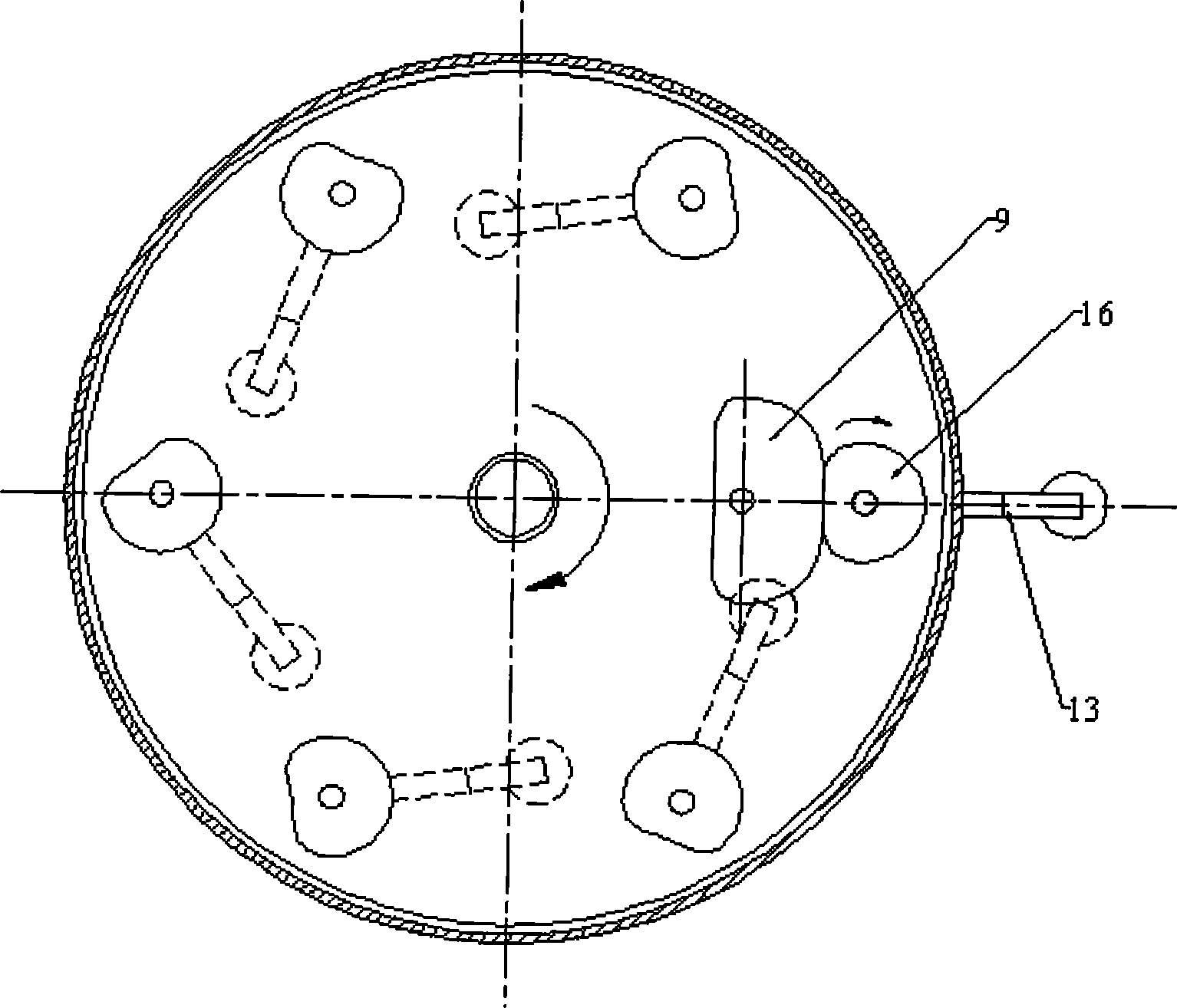

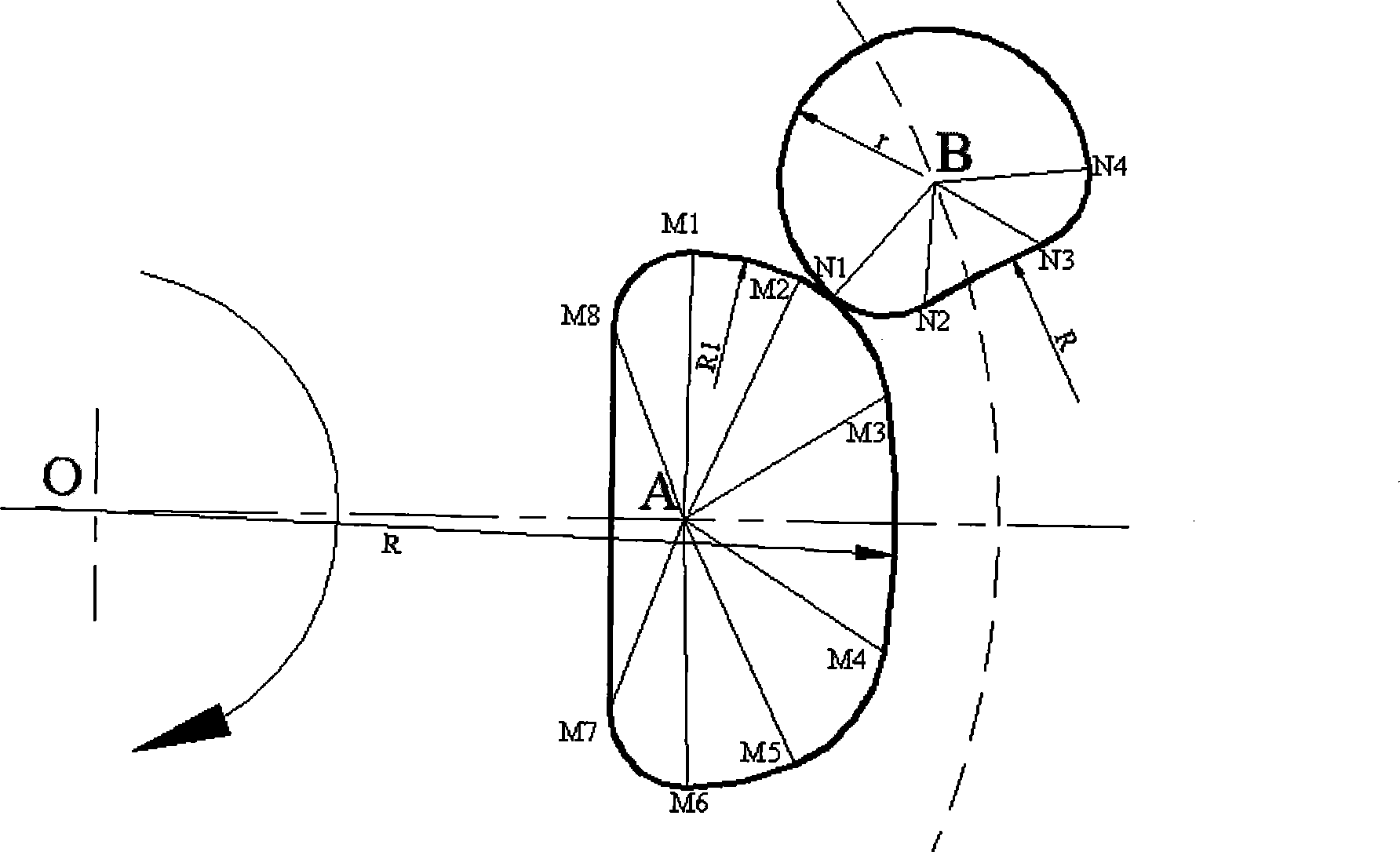

[0009] Such as figure 1 , figure 2 As shown, the six-claw actuator of the weeding robot is composed of a casing, a main shaft turntable system, a cutter shaft system, and a steel wire sliding rod system. Wherein the main shaft turntable system comprises a main shaft (2), a turntable (22), a key (21), a shaft end retaining ring (20), and a bolt (19). The main shaft (2) is supported by rolling bearings (3) and rotates relative to the housing (1). The turntable (22) is connected to the main shaft through a key (21), and is axially positioned through a shaft end retaining ring (20) and a bolt (19).

[0010] Cutter shafting comprises cutter (13), rotating shaft (14), snap ring (15), key (12), recessed locking wheel (16), shaft end retaining ring (11) and bolt (10). Cutter (13) is connected with rotating shaft (14) by bolt, and rotating shaft (14) can rotate relative to rotating disk (22), and carries out axial positioning by snap ring (15). The rotating shaft (14) is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com