Fire retardant floor and its manufacture method

A floor and flame-retardant layer technology, applied in the field of flame-retardant floor production, can solve the problems of no major breakthroughs in flame-retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

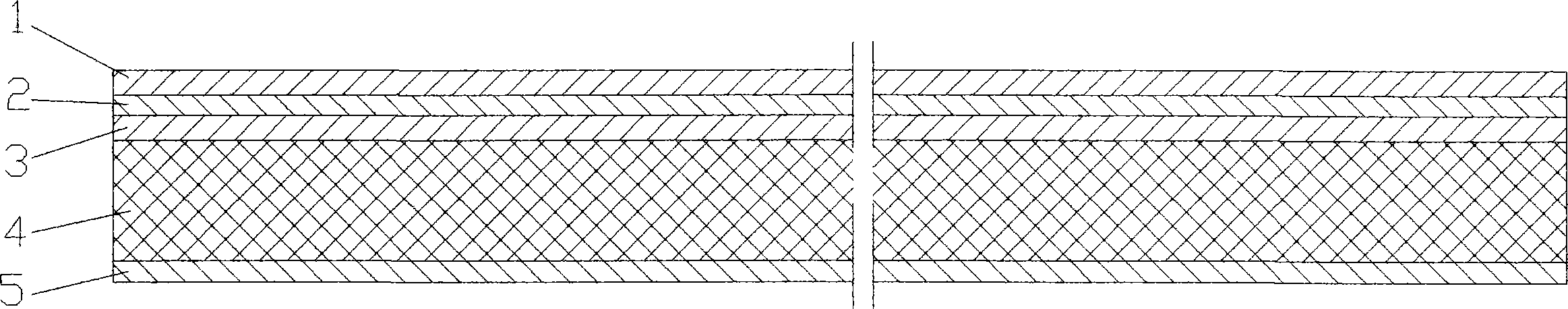

[0013] As shown in the drawings, the cross-sectional structure of the flame-retardant floor of the present invention is a wear-resistant layer 1, a decorative layer 2, a flame-retardant layer 3, a base material 4, and a balance layer 5 from top to bottom. The wear-resistant layer 1, the decorative layer 2, the base material 4, and the balance layer 5 all use the same material and the same treatment method as the prior art for pre-treatment. What is different from the existing floor is that the resistance of the present invention The flame retardant layer 3 is added between the decorative layer 2 and the base material 4 in the fire floor, and the flame retardant layer 3 is made of inorganic materials such as quartz cloth, aluminum silicate fiber cloth or asbestos cloth.

[0014] In order to further improve the flame retardant effect of the floor, the base material 4 is a flame retardant base material with flame retardant treatment, such as multilayer plywood or particle board or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com