Kite power generation method

A kite and wind direction technology, applied in wind power generation, wind engine, wind motor combination, etc., can solve the problem of low utilization rate of wind energy and achieve the effect of high utilization rate of wind energy, low maintenance cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

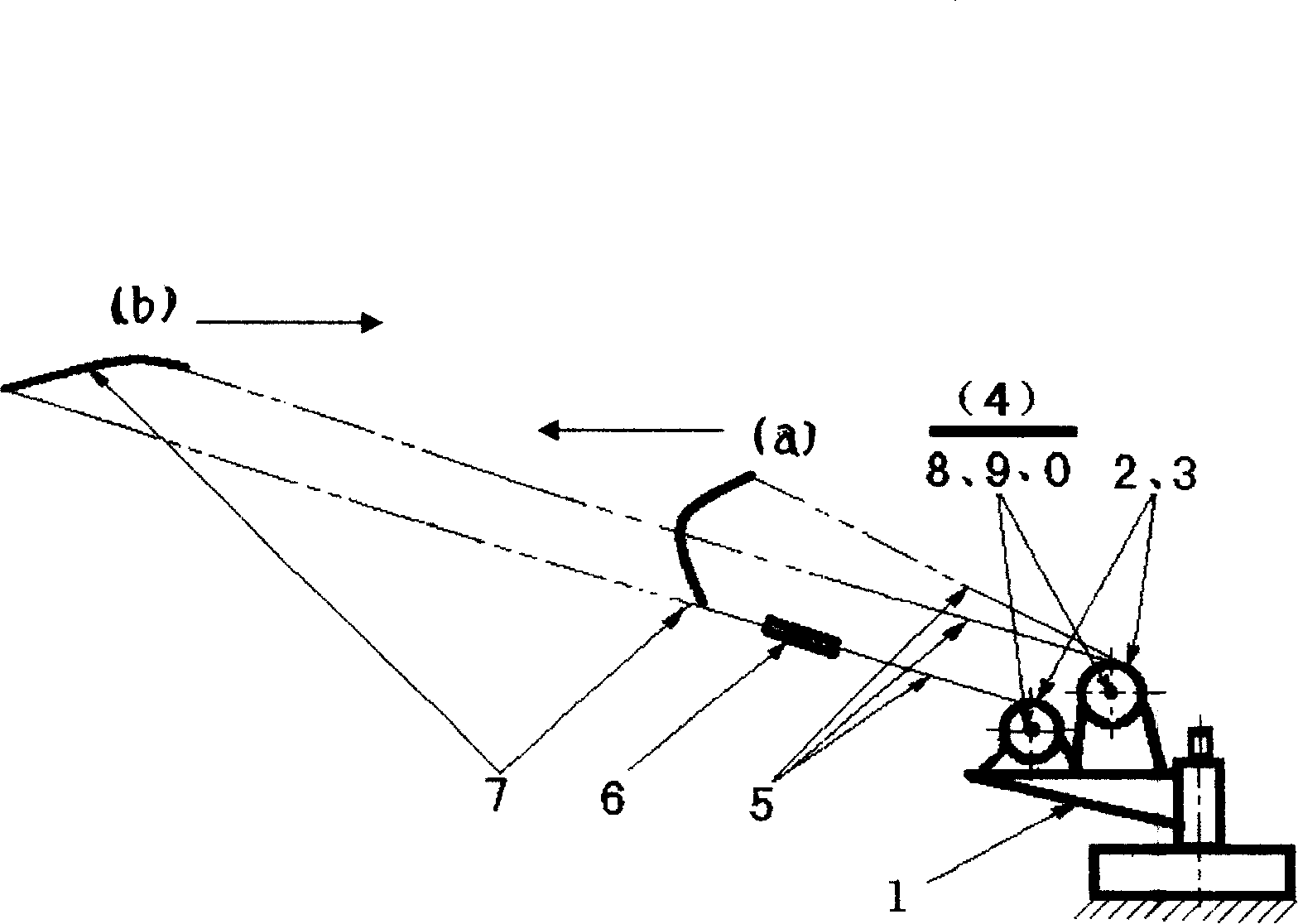

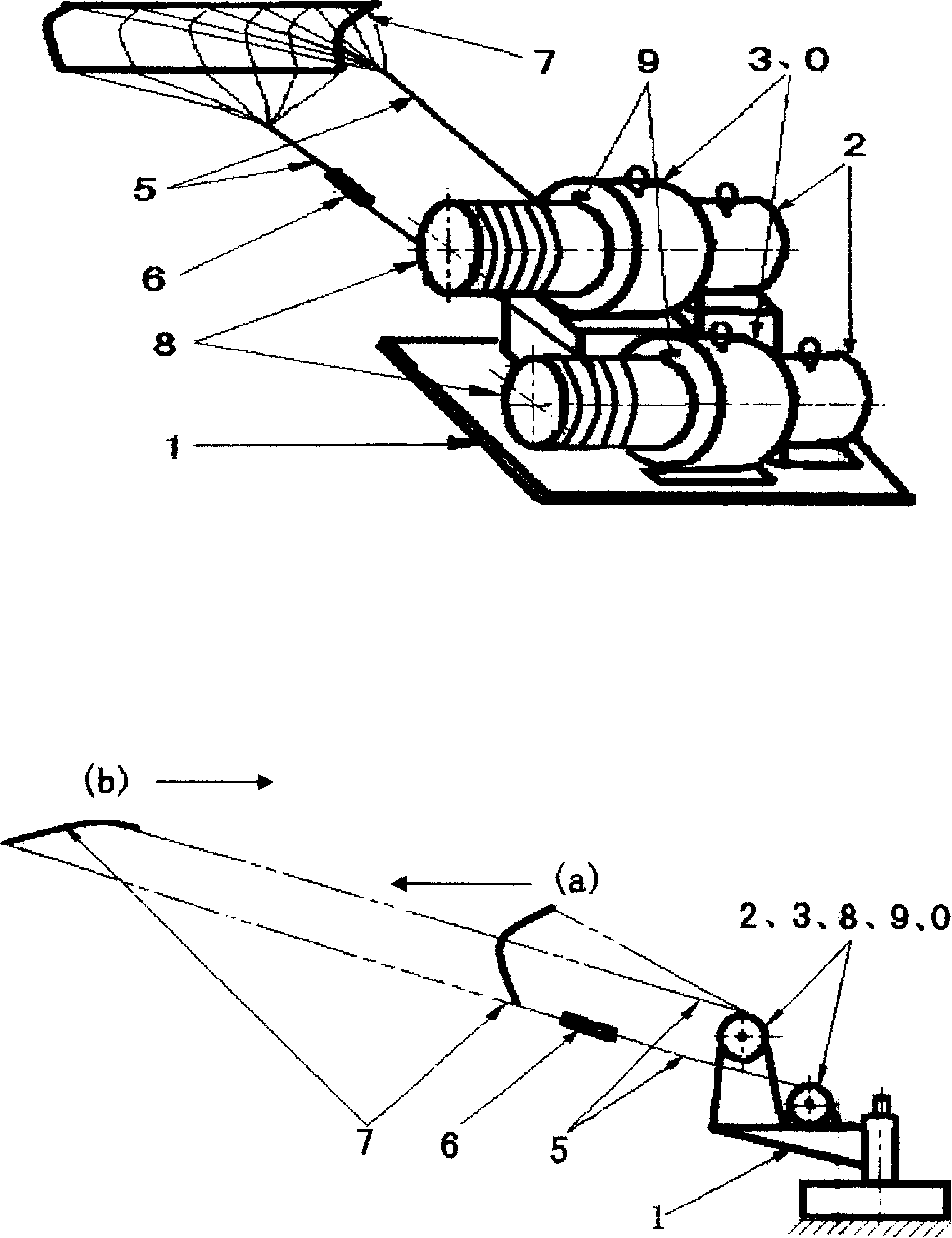

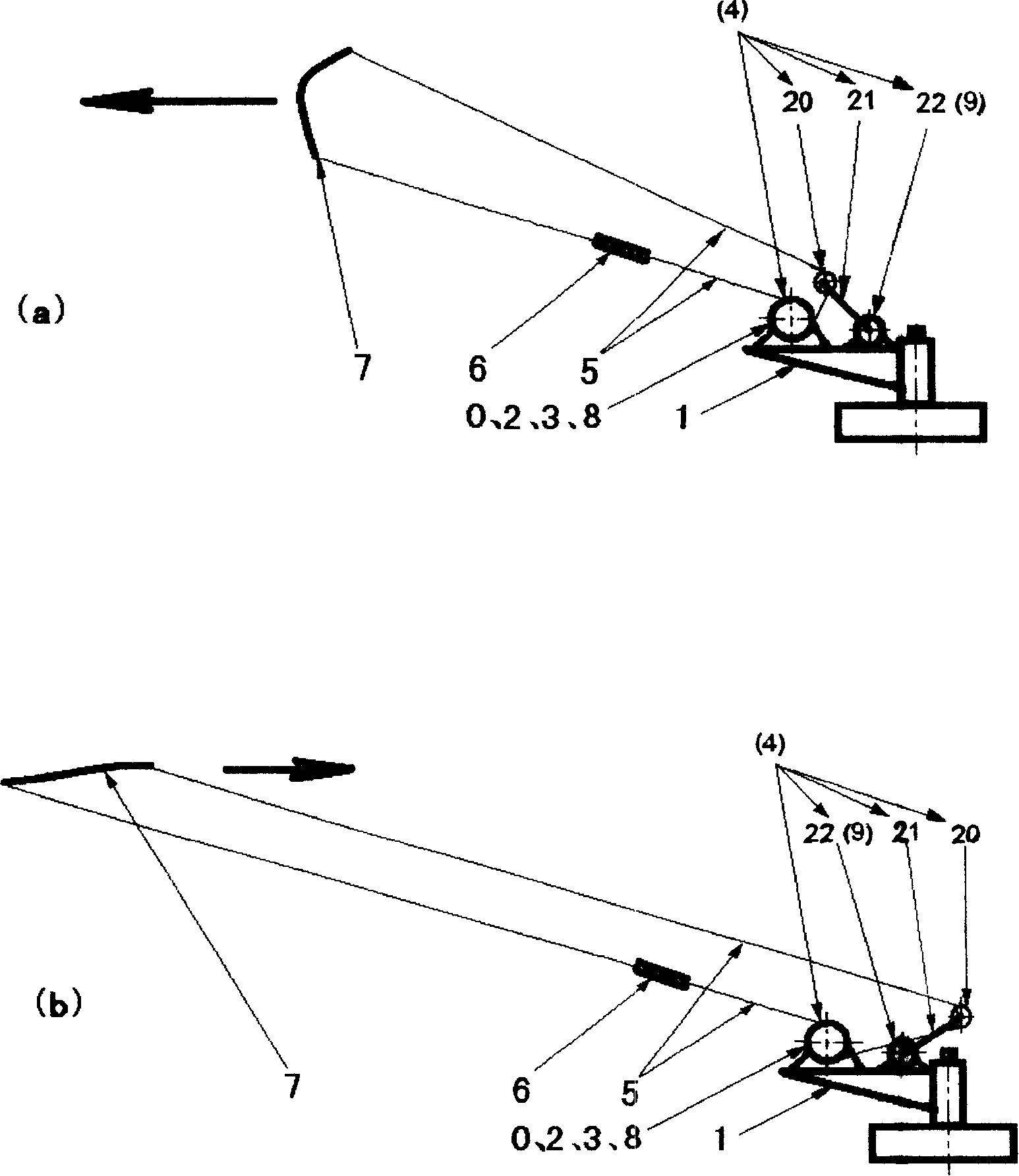

[0027] exist figure 2 In the shown first embodiment, the kite manipulating device: a generator / motor (2), a gearbox (3), a rope (5), an elastic safety device (6), and a kite are installed on the wind direction turntable (1). (7); Kite control device: it is composed of 2 to 4 winches (8), sensors, computer control devices (9), and electromagnet brakes (0). The working principle of the kite control device: the computer control device collects data through the sensor (9), and controls the work of each electromagnet brake (0) and hoist (8) respectively. When the position of the kite (7) is in (a) the computer controls the hoist (8), so that the windward area of the kite (7) is the largest, and the kite (7) provides the maximum pulling force. Kite (7) starts to pull winch (8) to do positive power by rope (5), elastic safety device (6), by gearbox (3), drags generation / motor (2) to generate electricity. When the rope is finished, the kite (7) controls the electromagnet brake (0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com