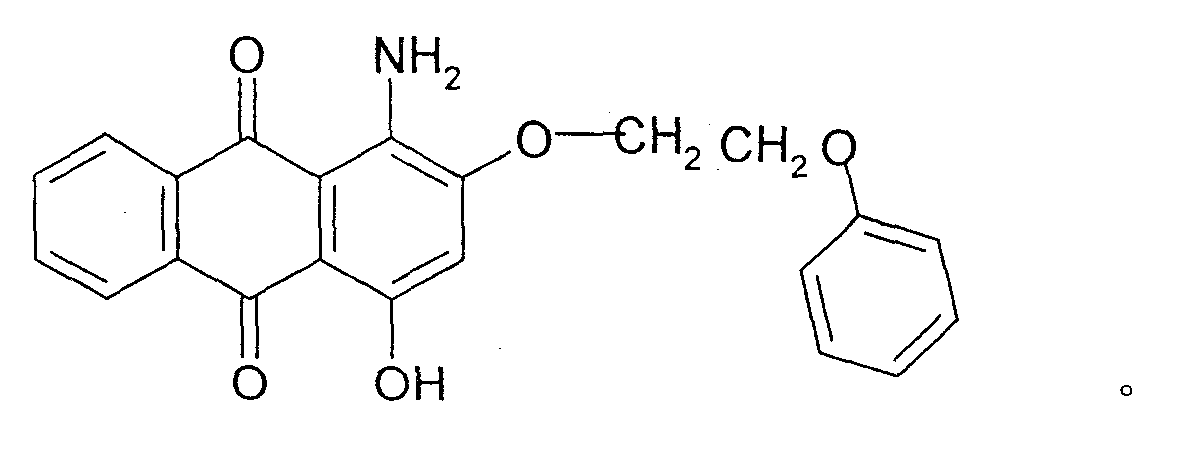

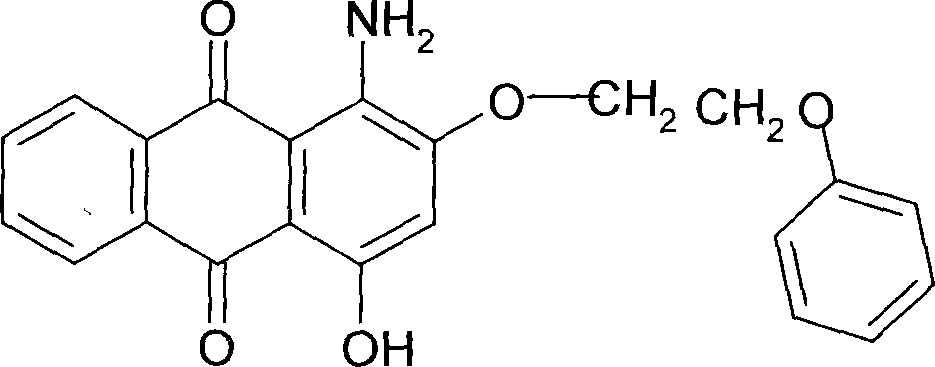

Technique for synthesizing improved disperse red 191

A technology for the preparation of disperse red, which is applied in the direction of amino-hydroxyanthraquinone dyes, etc., and can solve the problems that the product quality cannot be recognized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0004] 1. Put 600 kg of ethylene glycol monophenyl ether, 100 kg of OP series emulsifier, 300 kg of disperse red 60, and 150 kg of potassium carbonate into the reactor.

[0005] 2. Heat to 130-150 degrees, keep warm for 6 hours, touch the board to judge the end point, and start to cool down after the end point is reached.

[0006] 3. Below 60 degrees, start to add 800 kg of methanol (or ethanol) dropwise, and finish adding in 2 hours.

[0007] 4. After adding, press filter, wash to obtain the product, and dry to obtain 300 kg of product.

[0008] 5. Recover methanol (or ethanol), phenol, and ethylene glycol monophenyl ether from the mother liquor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com