Method for producing carbon fiber

A production method and technology of carbon fiber, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of surface fiber production and quality decline, production cost surge, high wind speed, etc., and achieve the effect of increasing production and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

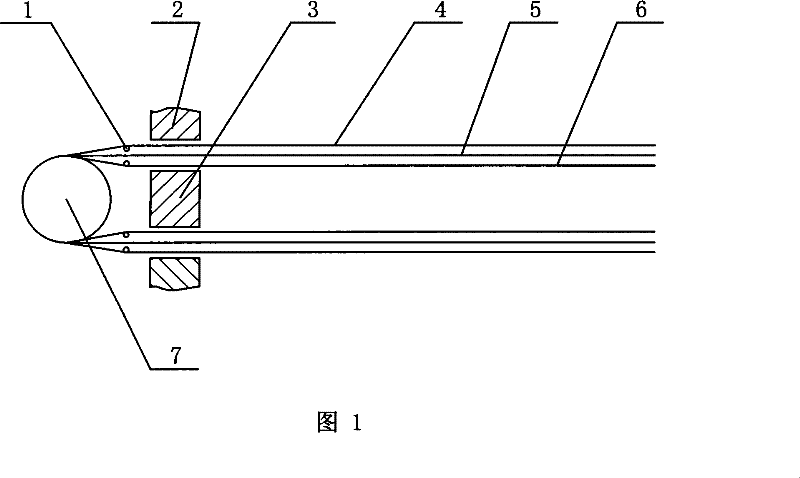

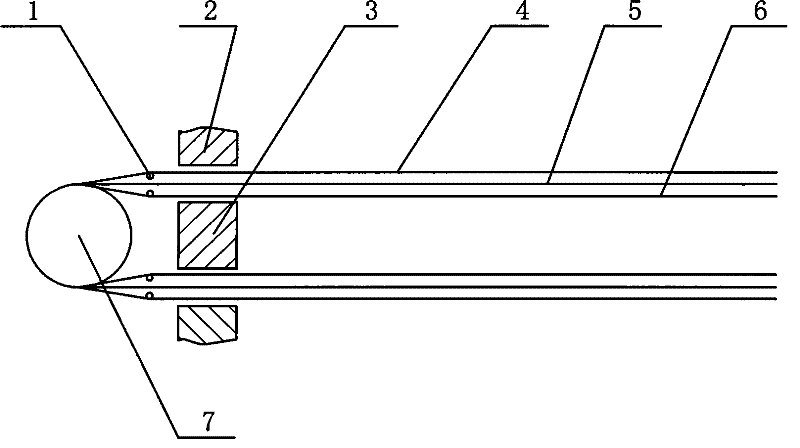

[0009] exist figure 1 Among them, multiple bundles of raw silk are unwound from the unwinding machine, and are divided into upper raw silk 4, middle raw silk 5, lower raw silk 6, between the upper raw silk 4 and the middle raw silk 5, the middle raw silk 5 and the lower raw silk 6 There is a guide roller 1 between them, and then through the traction of two guide rollers 1, the upper layer of raw silk 4, the middle layer of raw silk 5, and the lower layer of raw silk 6 are arranged on the guide rollers to form a cloth surface. The raw silk 5 and the lower-layer raw silk 6 enter the oxidation furnace in the form of cloth arranged in three layers between the upper furnace plate 2 and the lower furnace plate 3 of the furnace mouth for pre-oxidation treatment. The distance between 5 and the upper layer of raw silk 4 and the lower layer of raw silk 6 is ≥ 5mm. The raw silk entering the oxidation furnace is affected by the hot air blown from different directions in the furnace. Under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com