Ironing machine for shirt and mantle for anthropometric dummy installation

A mannequin and ironing machine technology, which is applied in the field of shirt ironing machines, can solve the problems of cover damage, breakage, labor-intensive and time-consuming cover, and achieve the effect of simplifying the replacement operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the best mode for carrying out the present invention will be described.

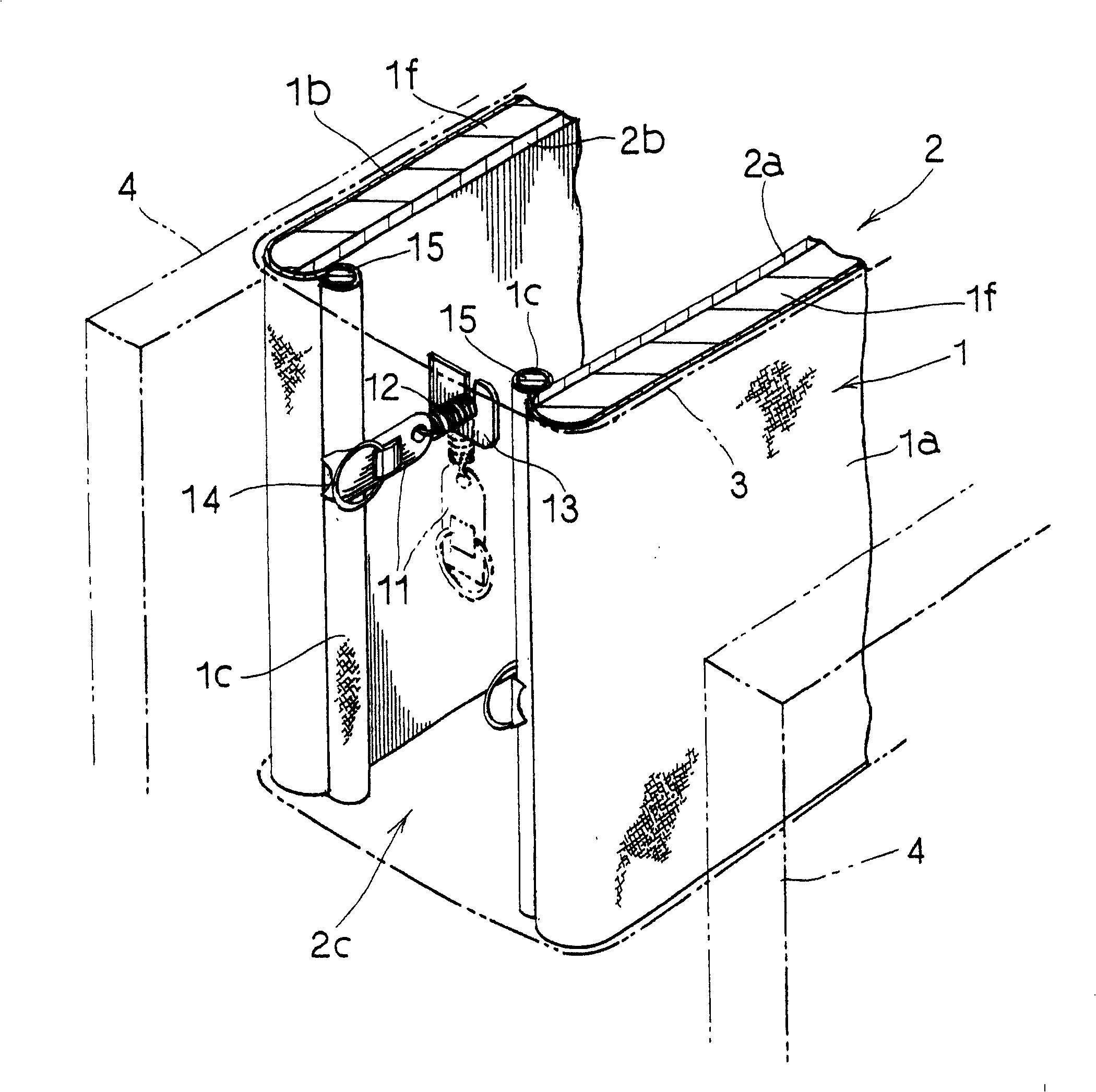

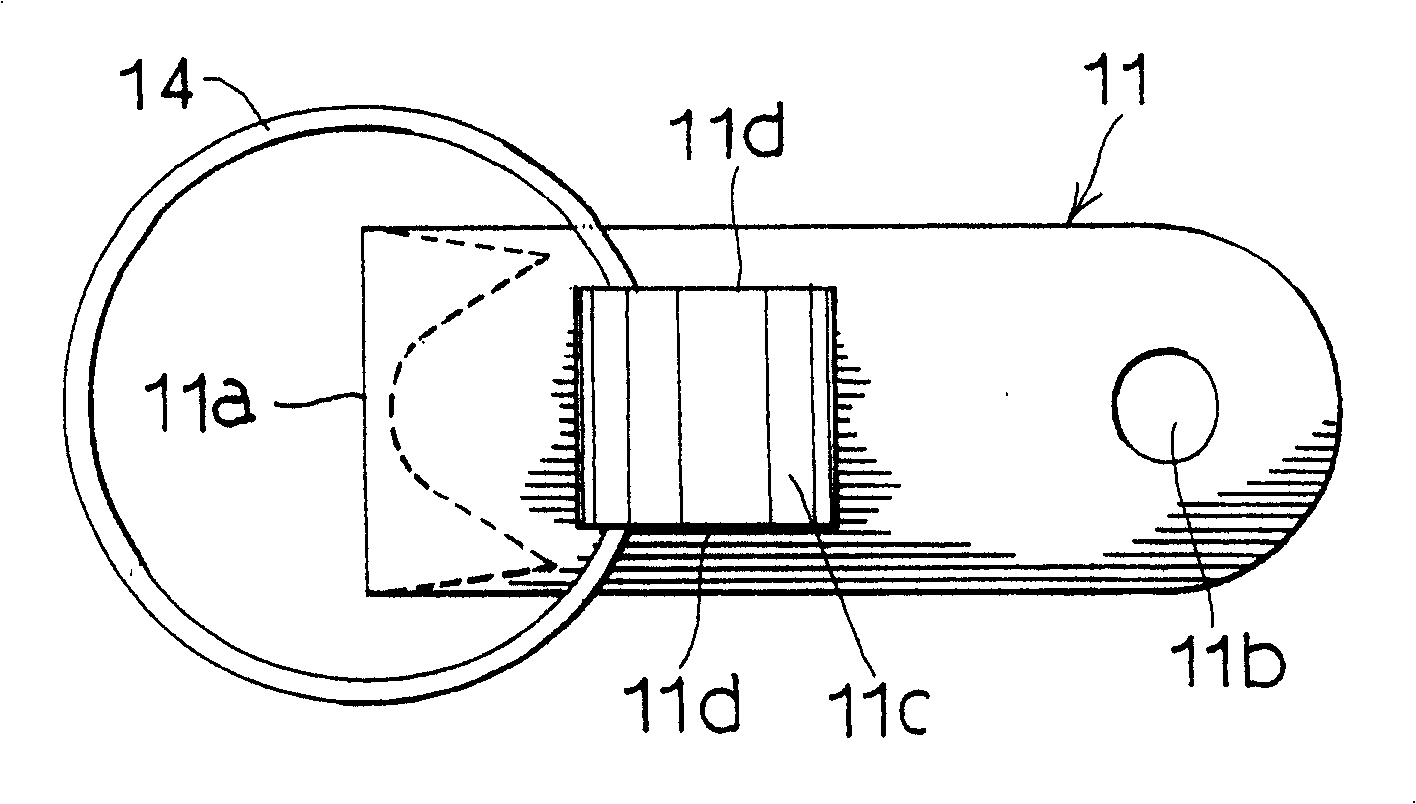

[0030] Such as figure 1 etc., the shirt ironing machine of the present invention has: a mannequin 2, which is covered by a cover 1; an iron 4, which presses the front and rear of the mannequin 2, so as to wear on the mannequin 2 Wait for the shirt 3 to be pressed and set. The said human body model 2 is formed in the shape which opened the side part 2c by the board|plate 2a, 2b arrange|positioned facing front and back.

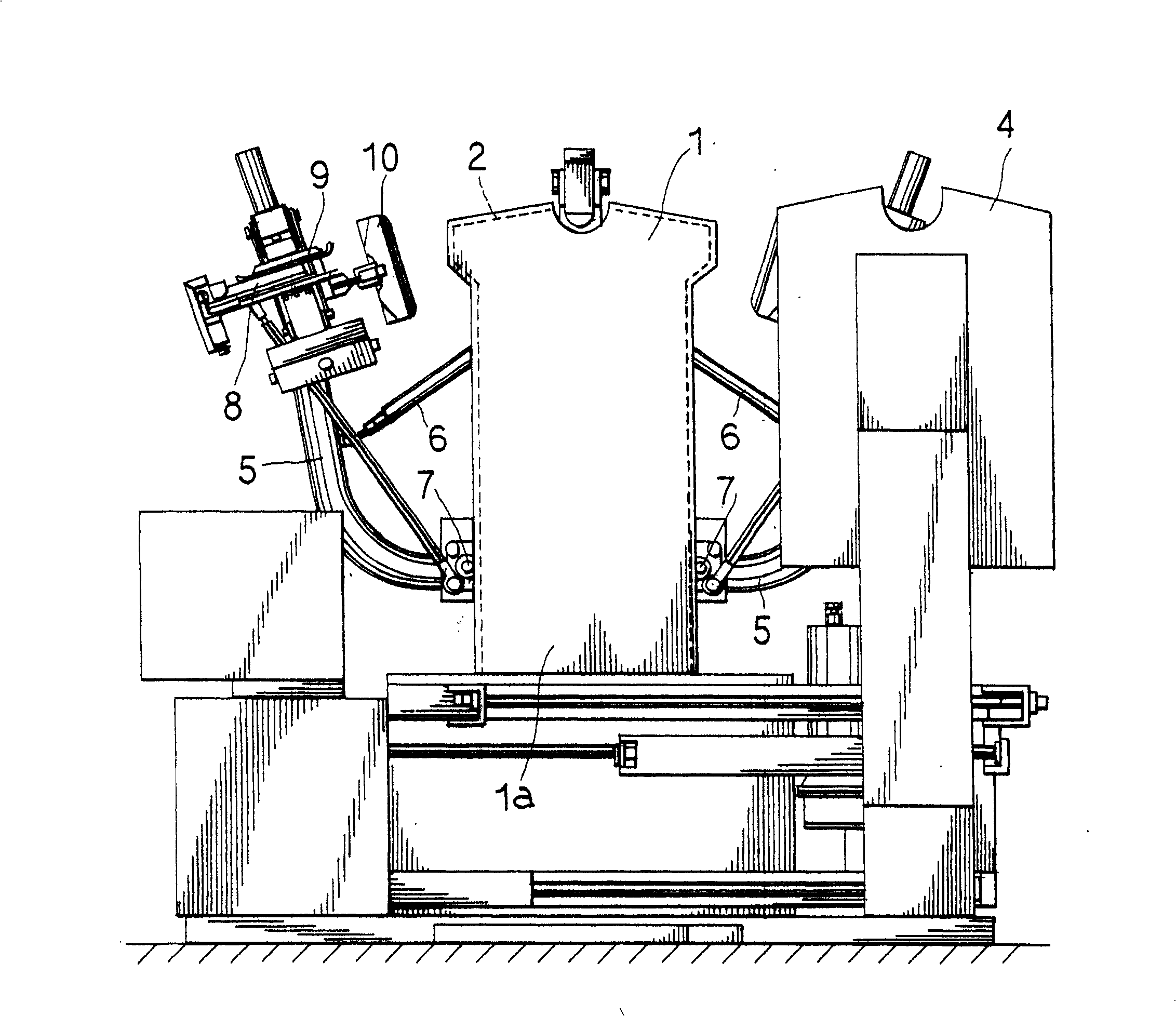

[0031] Iron 4 is in this embodiment such as figure 2 As shown, it is arranged on the side of the human body model 2, and is formed in the front and rear positions of the human body model 2 in a slidable manner. In addition, this iron 4 is formed so that steam can be supplied inside for heating.

[0032] 5 is a pair of left and right support arms arranged on both sides of the human body model 2 . The support arm 5 is formed by the air cylinder 6 so that it can til...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap