Oil-contained bearing

A bearing and oil tank technology, applied in the field of oil bearing design, can solve the problems of reduced oil storage volume, easy generation of clumps, rotating friction, etc., and achieve the effect of increasing oil storage volume, better rotating lubrication effect, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

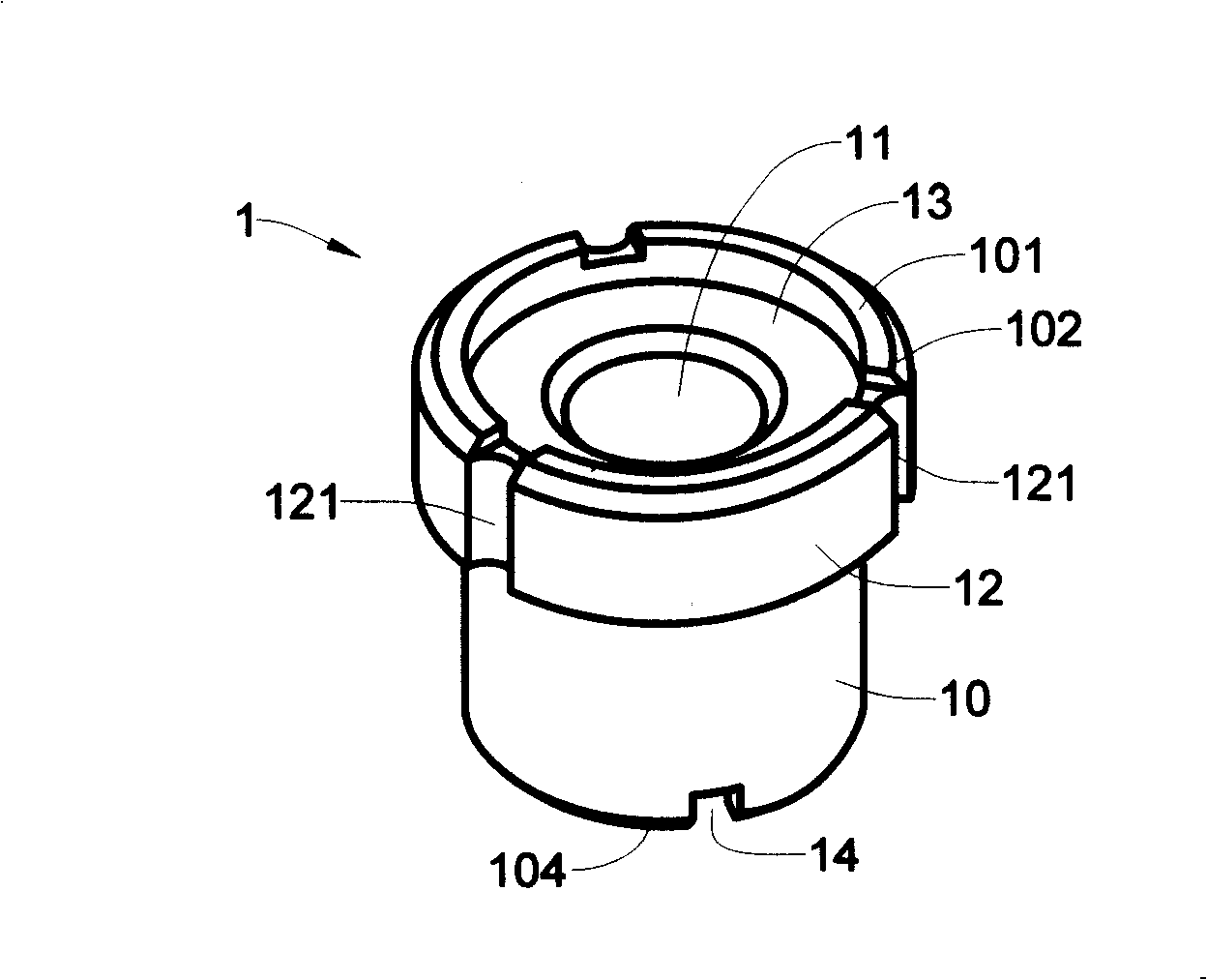

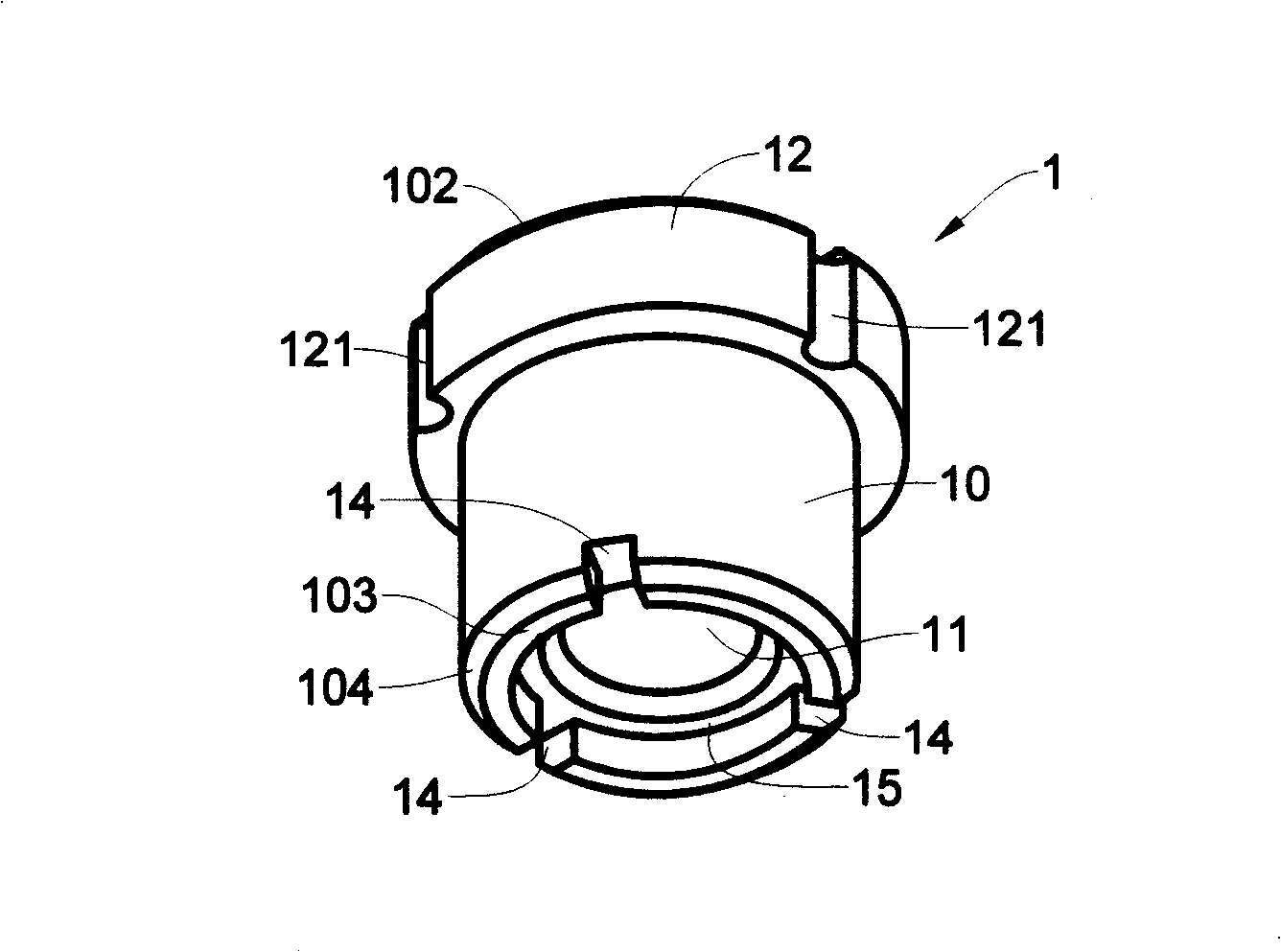

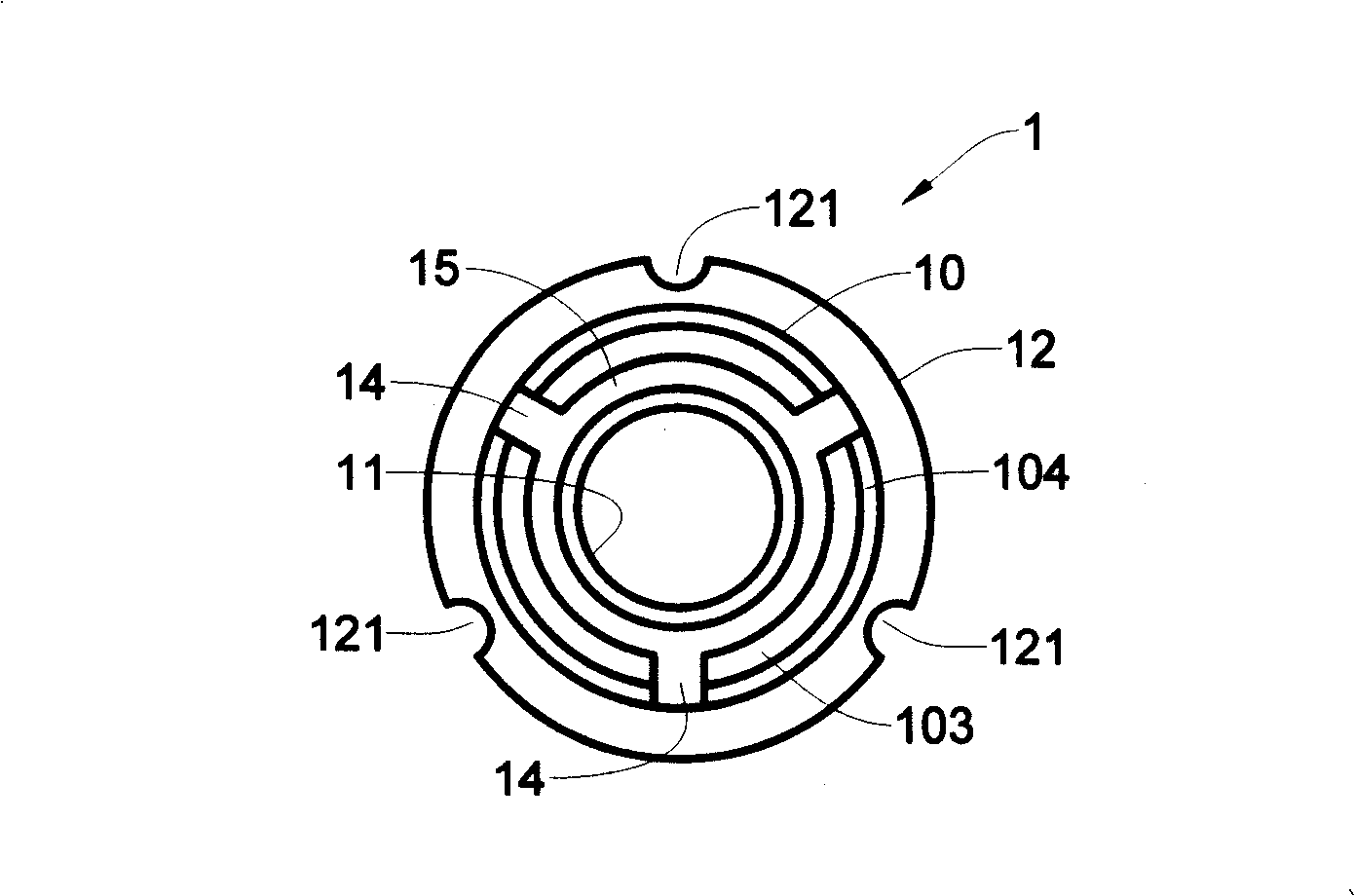

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028] Cooperate with reference Figure 1 to Figure 4 As shown, wherein the oil-impregnated bearing (1) of the present invention has a cylindrical body (10), a perforation (11) is set in the body (10), and a crown with an enlarged diameter is formed at the upper edge of the body (10). part (12), the length of the crown (12) is less than the length of the body (10), and an annular groove (13) is set at the inner edge of the top of the body (10), the annular groove (13) is located in the crown (12), The surface of the crown (12) is provided with several grooves (121), and the bottom (103) of the body (10) is provided with an oil groove (15), and the periphery of the oil groove (15) is provided with several grooves (14), and the groove (14 ) and the groove (121) on the surface of the crown (12) form a dislocation shape.

[0029] The top (101) of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com