Inside spline stick space vernier caliper

A vernier caliper and rod spacing technology, applied in the field of length measuring tools, can solve the problems of low measurement efficiency, unsuitability, and great influence on measurement accuracy, and achieve the effects of high measurement efficiency, convenient detection, and simple measurement operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

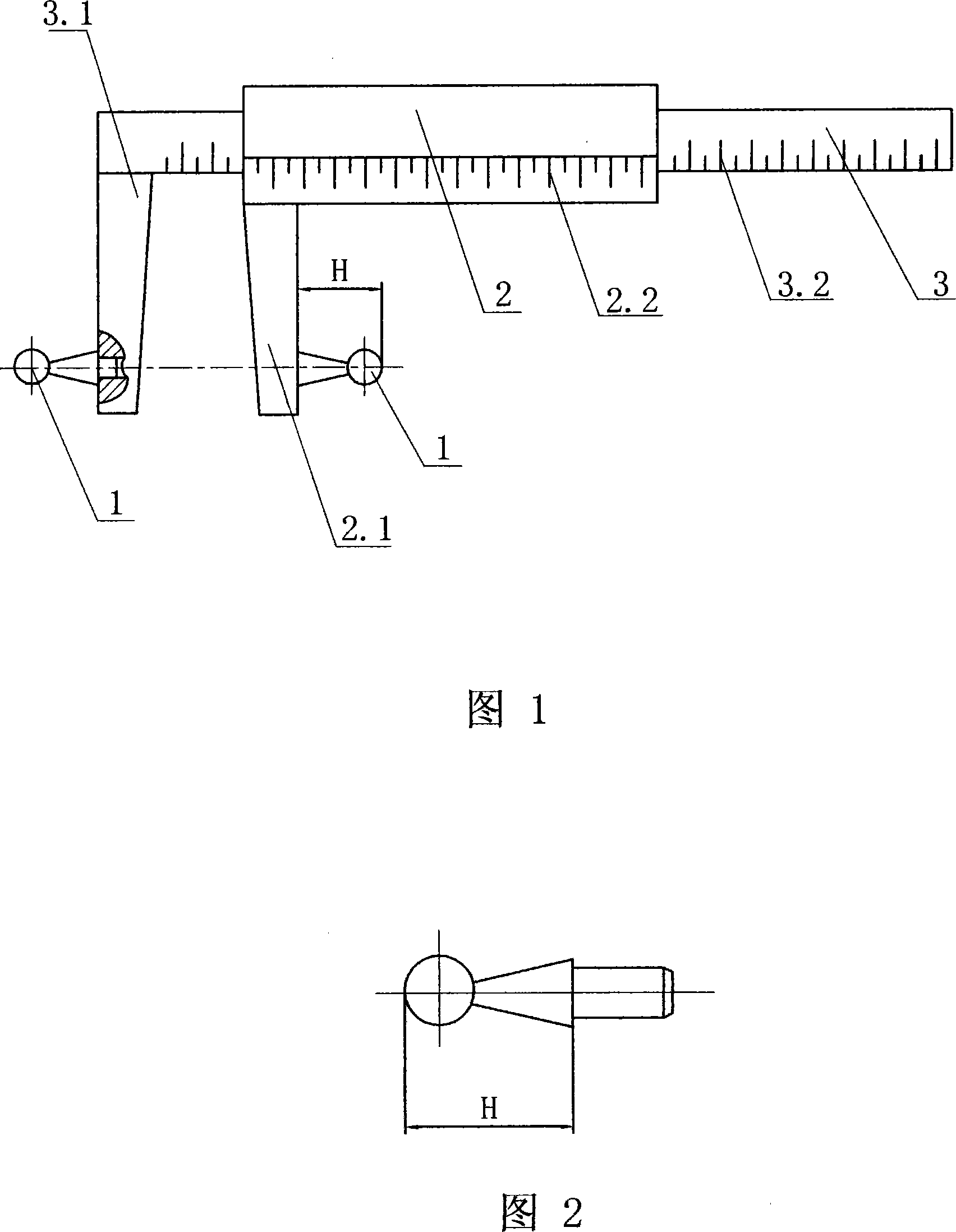

[0014] The internal spline bar pitch vernier caliper shown in the accompanying drawing includes a ball measuring head 1, an auxiliary scale 2 and a main scale 3. The surface of the cross bar of the main chi 3 is provided with a scale 3.2, and the drooping bar of the main chi 3 is a left measuring claw 3.1. The cross bar surface of described auxiliary chi 2 is provided with scale 2.2, and auxiliary chi 2 is sleeved on the main chi 3 cross bar and can move left and right, and the drooping bar of auxiliary chi 2 is the right measuring claw 2.1. The outside of the head of the left measuring claw 3.1 and the right measuring claw 2.1 is equipped with a ball measuring head 1, and the two ball measuring heads 1 are on the same axis and are parallel to the cross bar of the main scale 3. The two ball probes 1 used to measure the splines in the same size have the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com