Elastic hinge parallel 6-UPS six-dimension force-measuring platform

A 6-UPS, elastic hinge technology, applied in the field of force sensors, can solve the problems of pre-tightening force variation and limitation, and achieve the effects of stable performance, simple structure, and easy analysis and modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

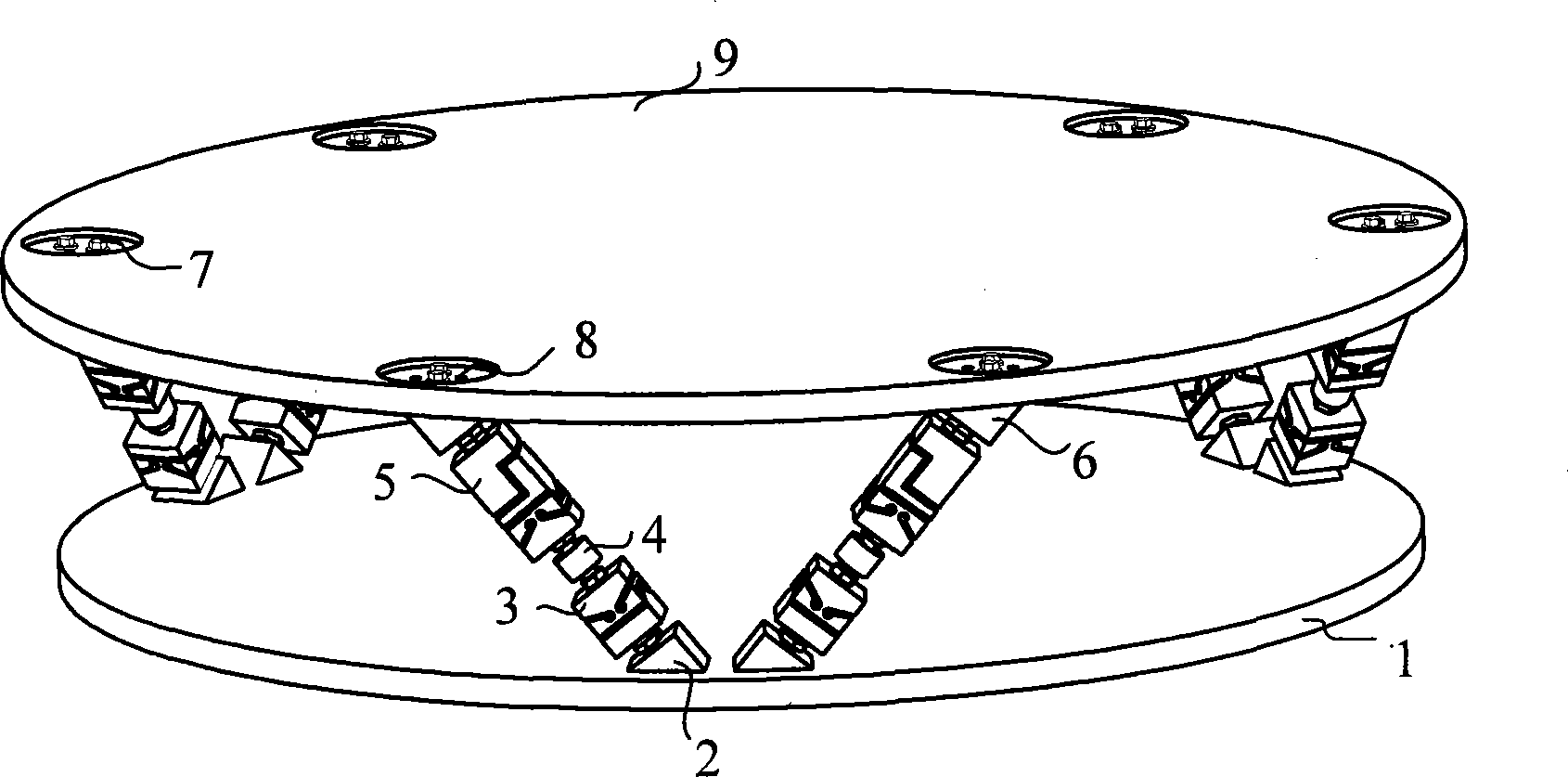

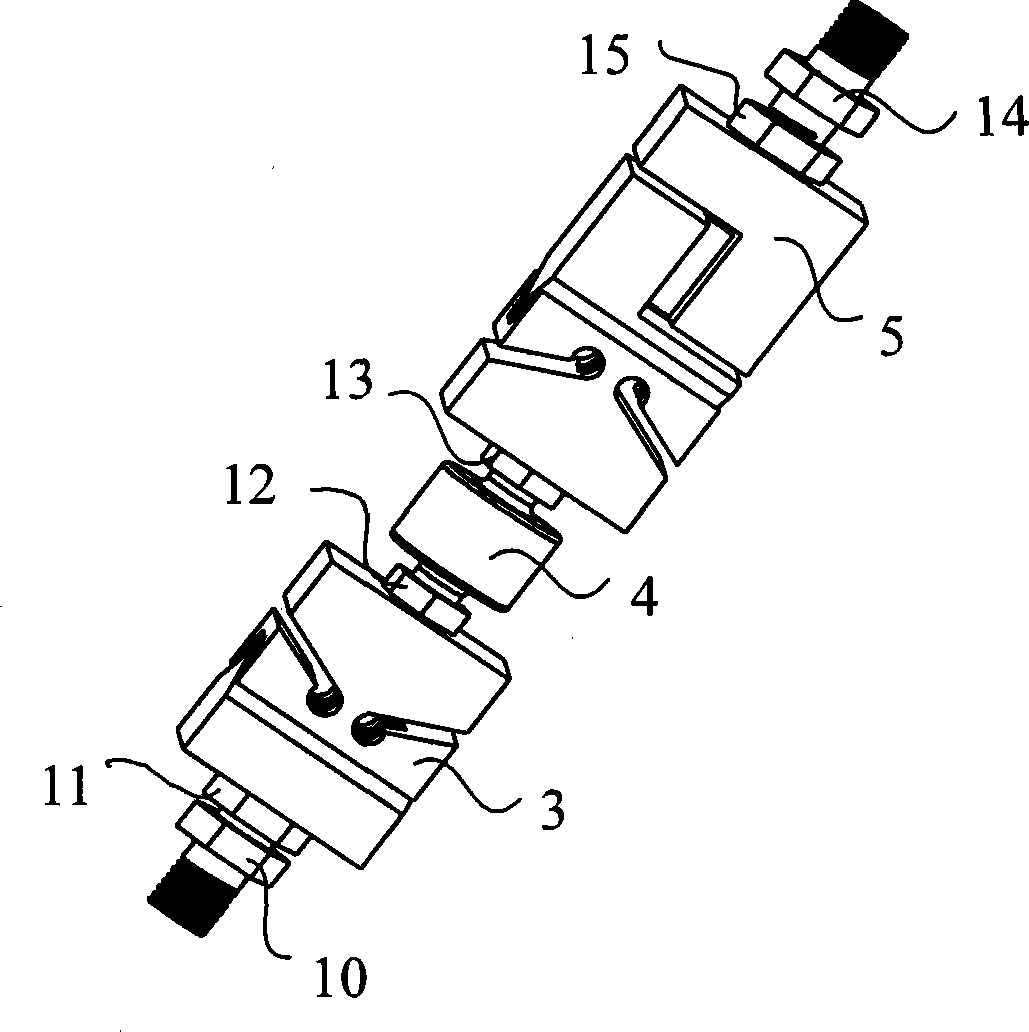

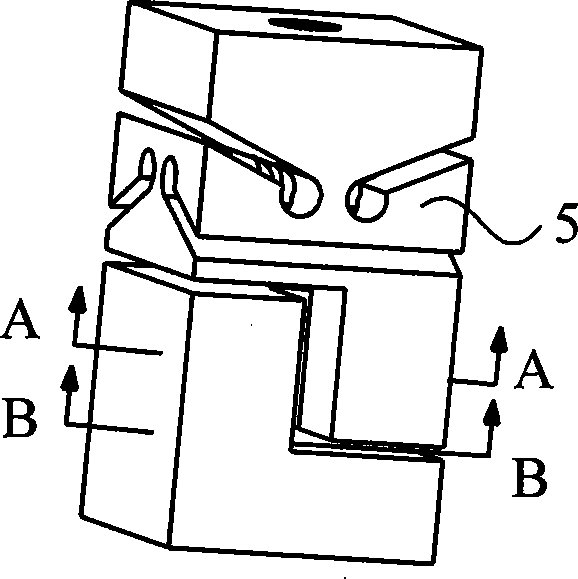

[0021] figure 1 It is an embodiment disclosed by the present invention. The assembled one-dimensional force-measuring branch is respectively connected with the foundation platform 1 and the loading platform 9 through fastening bolts 7, positioning pins 8 and upper and lower positioning blocks (6, 2). The assembled one-dimensional force measuring branch consists of lock nut 11, stud bolt 10, integrated elastic universal hinge 3, lock nut 12, one-dimensional force sensor 4, lock nut 13, integrated elastic ball hinge 5, lock The lock nut 15 is connected with the stud bolt 14, and the lock nuts 11, 12, 13 and 15 are used for locking after threaded connection to prevent the thread from loosening during force measurement. The shape of the one-piece elastic universal hinge 3 is a cuboid, and two slits are respectively processed on two sets of opposite sides thereof. The angle between the two slits is 110°. Make the cuboid an integral elastic universal hinge whose axes intersect per...

Embodiment 2

[0023] Figure 6 For the second embodiment of the present invention, the one-dimensional force measuring branch is an integral one-dimensional force measuring branch 17, which is formed at one time. Its middle part is a cuboid structure, and the outer surface of the cuboid middle part is pasted with strain gauges 16 as force sensitive element. The integral one-dimensional force measuring branch is connected with the foundation platform 1 and the loading platform 9 through fastening bolts 7 and positioning pins 8 .

Embodiment 3

[0025] Figure 8 As the third embodiment of the present invention, the one-dimensional force-measuring branch is an inner cavity integral one-dimensional force-measuring branch 20, which is formed by one-time processing. The middle part of the cuboid is processed with a hollow cavity, and the two sides of the cavity are Strain gauge 16 is housed. The integral one-dimensional force-measuring branch of the inner cavity is connected with the positioning blocks (6, 2) fixed on the foundation platform 1 and the loading platform 9 through cylindrical pins 21, respectively.

[0026] The one-dimensional force-measuring branch can be replaced by one-dimensional linear micro-drive branch, so that the force-measuring platform becomes a six-dimensional precision positioning platform; the middle part of the one-dimensional linear micro-drive branch is a cuboid structure, and the middle part of the cuboid is processed with a cavity with upper and lower bosses The piezoelectric ceramic line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com