Scraping machine and non-material testing apparatus

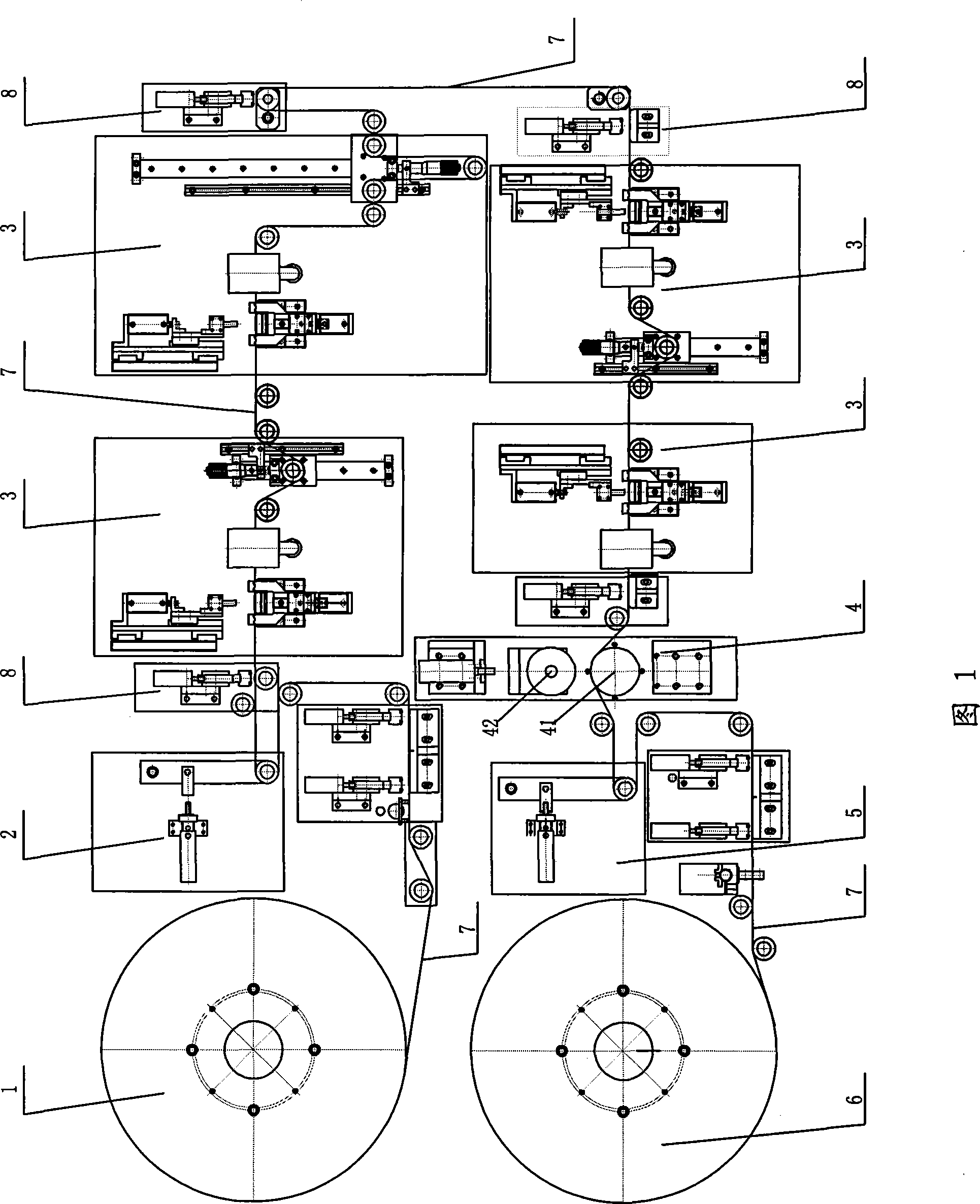

A detection device and scraper technology, applied in the direction of testing moving plates, electrode manufacturing, alkaline battery electrodes, etc., can solve problems such as failure to detect the use of pole pieces on the unwinding roll, loud noise, machine damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

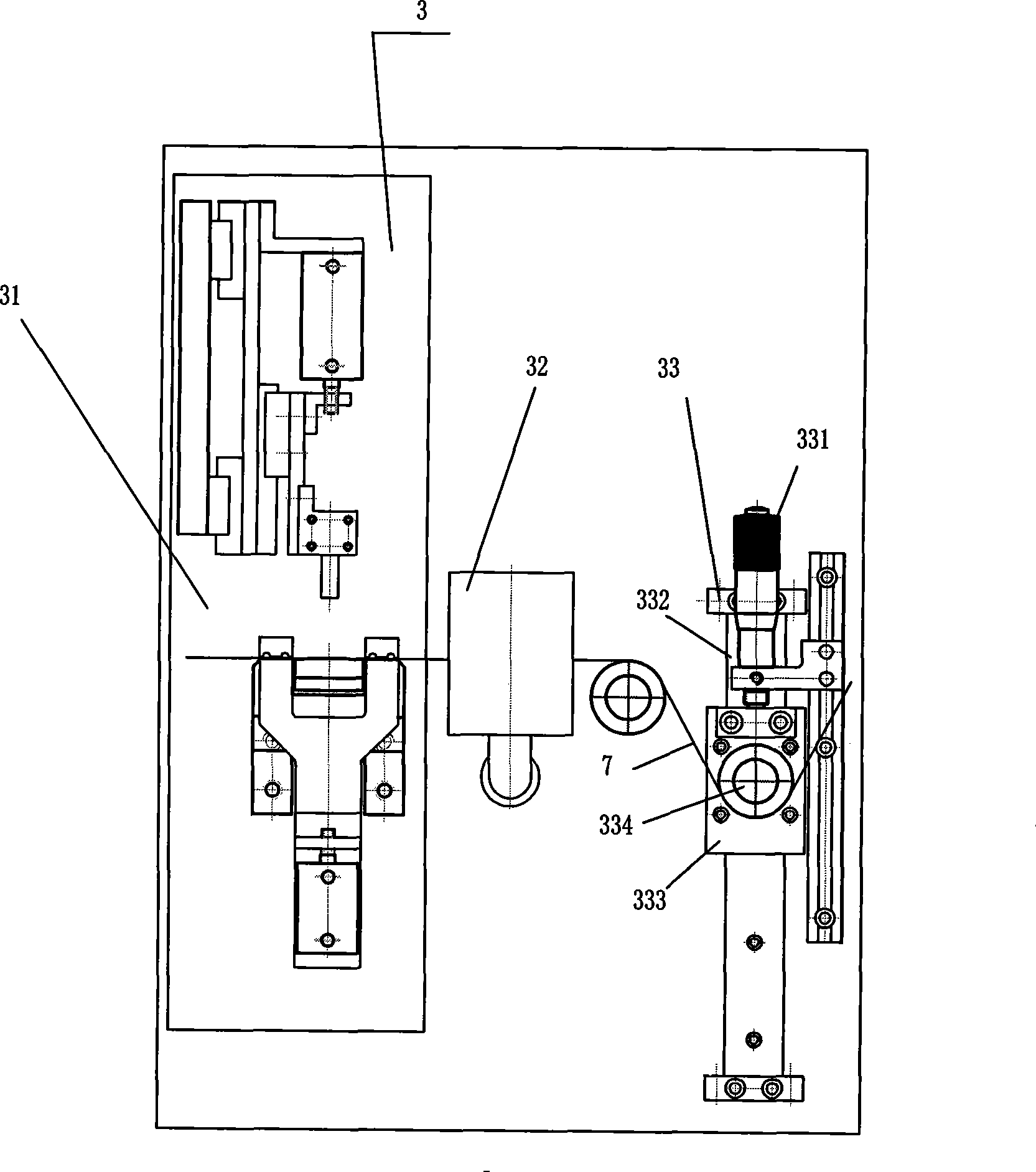

Method used

Image

Examples

Embodiment Construction

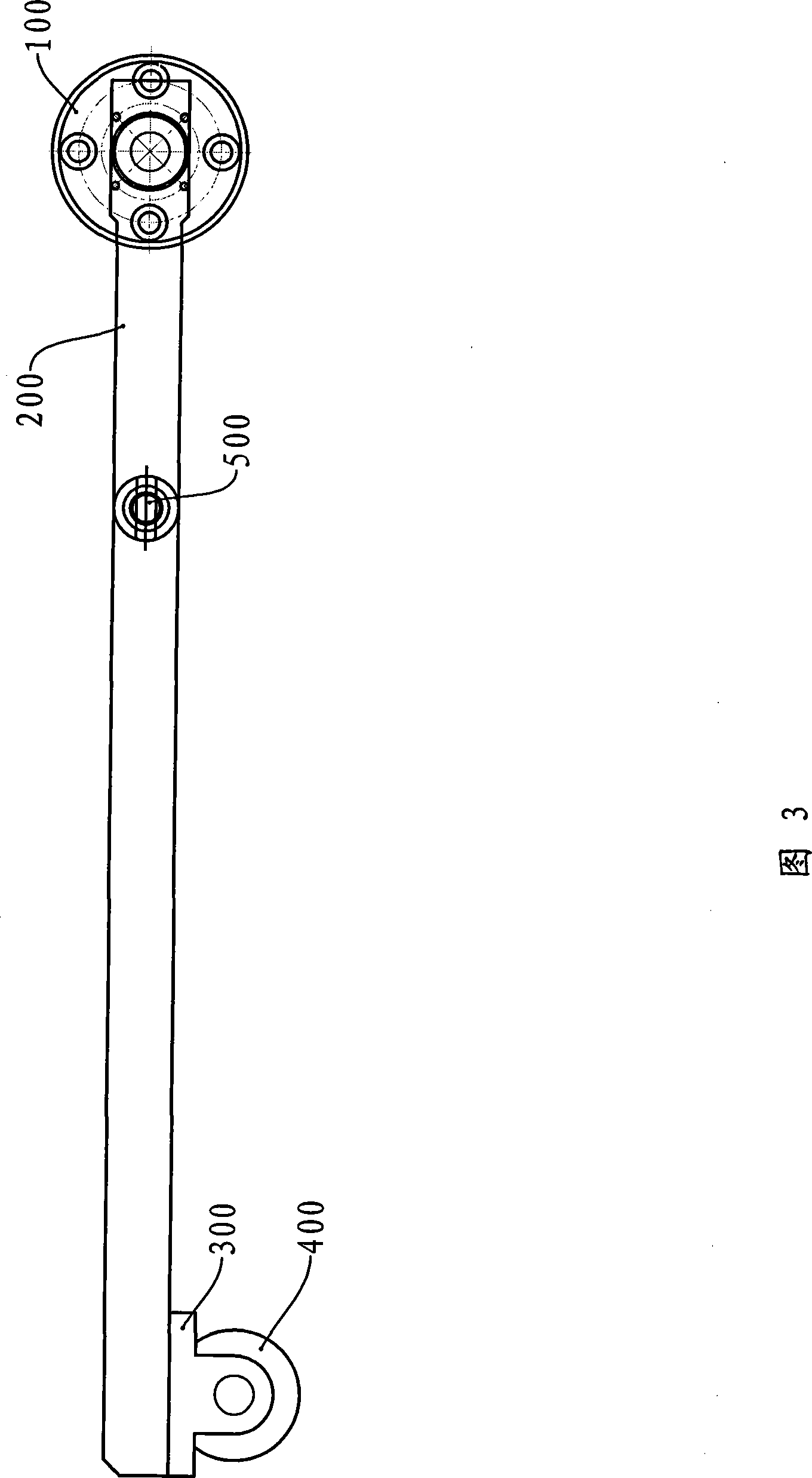

[0046] See Figure 3 and Figure 4 , The material-free detection device includes a photoelectric support 900, which is fixed on the panel 800 of the scraper frame, and a photoelectric detection element (not marked) is installed on the photoelectric support 900. The photodetection element includes a phototransmitter and a photoreceiver. The rotating shaft 100 passes through the panel 800 through the bearing 101 , the rotating shaft 100 can rotate relative to the panel 800 along its axial direction, and the rotating shaft 100 is radially fixed to the panel 800 . A photoelectric detection sheet 1000 is installed at the end of the rotating shaft close to the photoelectric bracket 900. The photoelectric detection sheet 1000 has a rotating sector section that can block the photoelectric signal, and the other end is fixedly connected with a rotating rod 200 perpendicular thereto. One end of the rotating rod 200 is connected to the rotating shaft 100 , and the other end is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com