Assembly soldering plate welded seam finite element modeling method based on vehicle collision simulation

A modeling method and tailor-welded blank technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems such as the report that no tailor-welded blank welding seam modeling method has been found, and achieve simple node layout, The effect of high simulation solution stability and high simulation solution efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

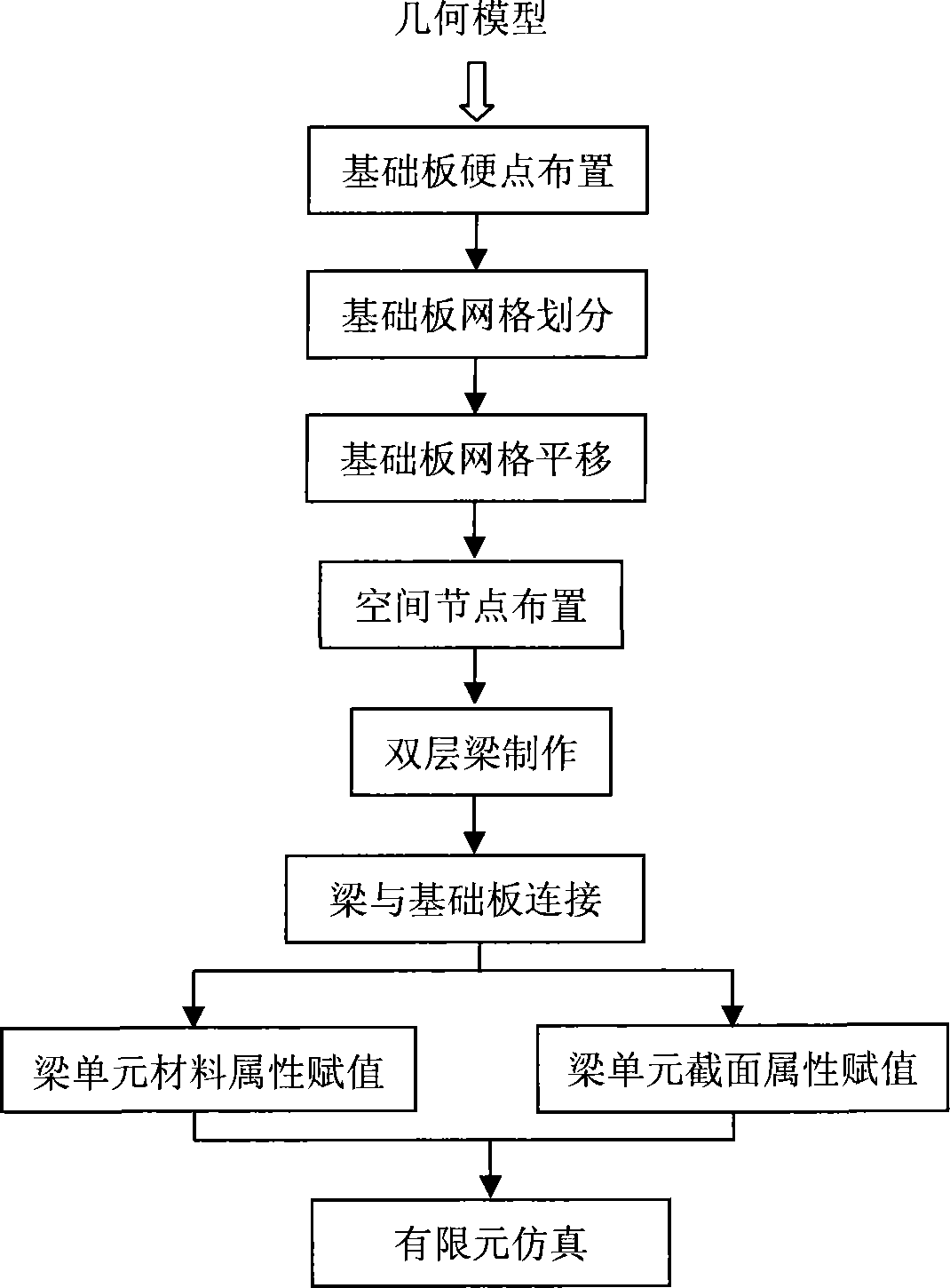

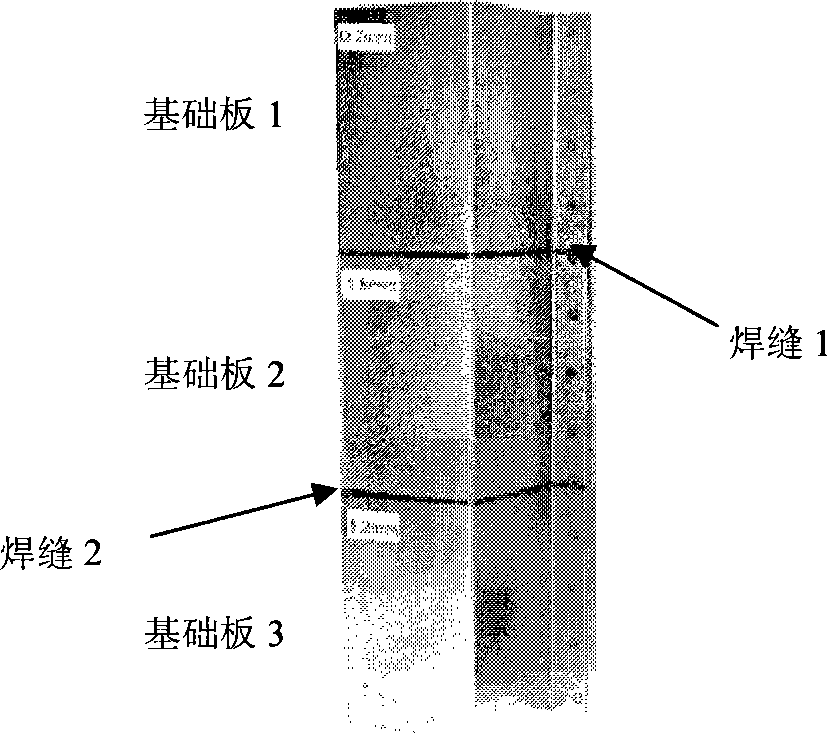

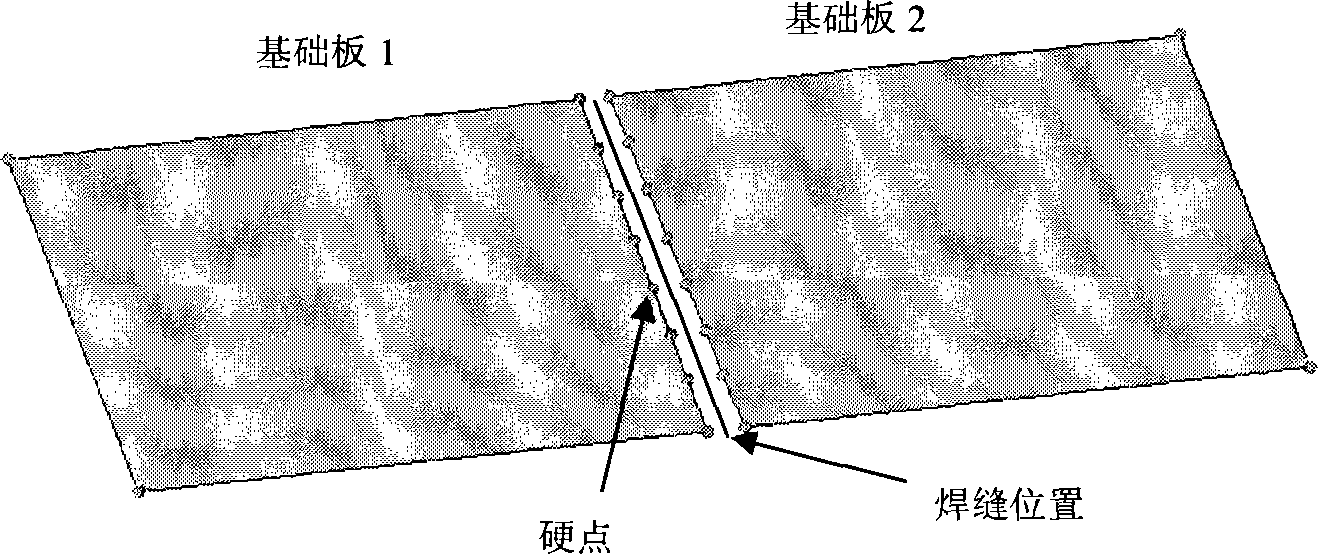

[0034] The following examples are as follows figure 1 The process shown is carried out, simulating the vertical weight of 293.3kg in the case of a tailor-welded blank hat-shaped straight beam composed of three sections of foundation plates (base plate 1, base plate 2, and base plate 3) fixed at one end The drop hammer hits at an initial velocity of 42km / h. The total length of the hat-shaped beam is 1000mm, which is divided into two welds (weld 1 and weld 2) evenly into tailor-welded welds with thicknesses of 0.7mm, 1.8mm and 1.2mm respectively. Motherboard, section s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com