Electric motor having a coaxially associated pump

A technology of coaxial arrangement and electric motor, which is applied in the field of electric motors, can solve the problems of weakening the hub-shaft connection of the flywheel, achieve the effect of improving the cooling effect and reducing the risk of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

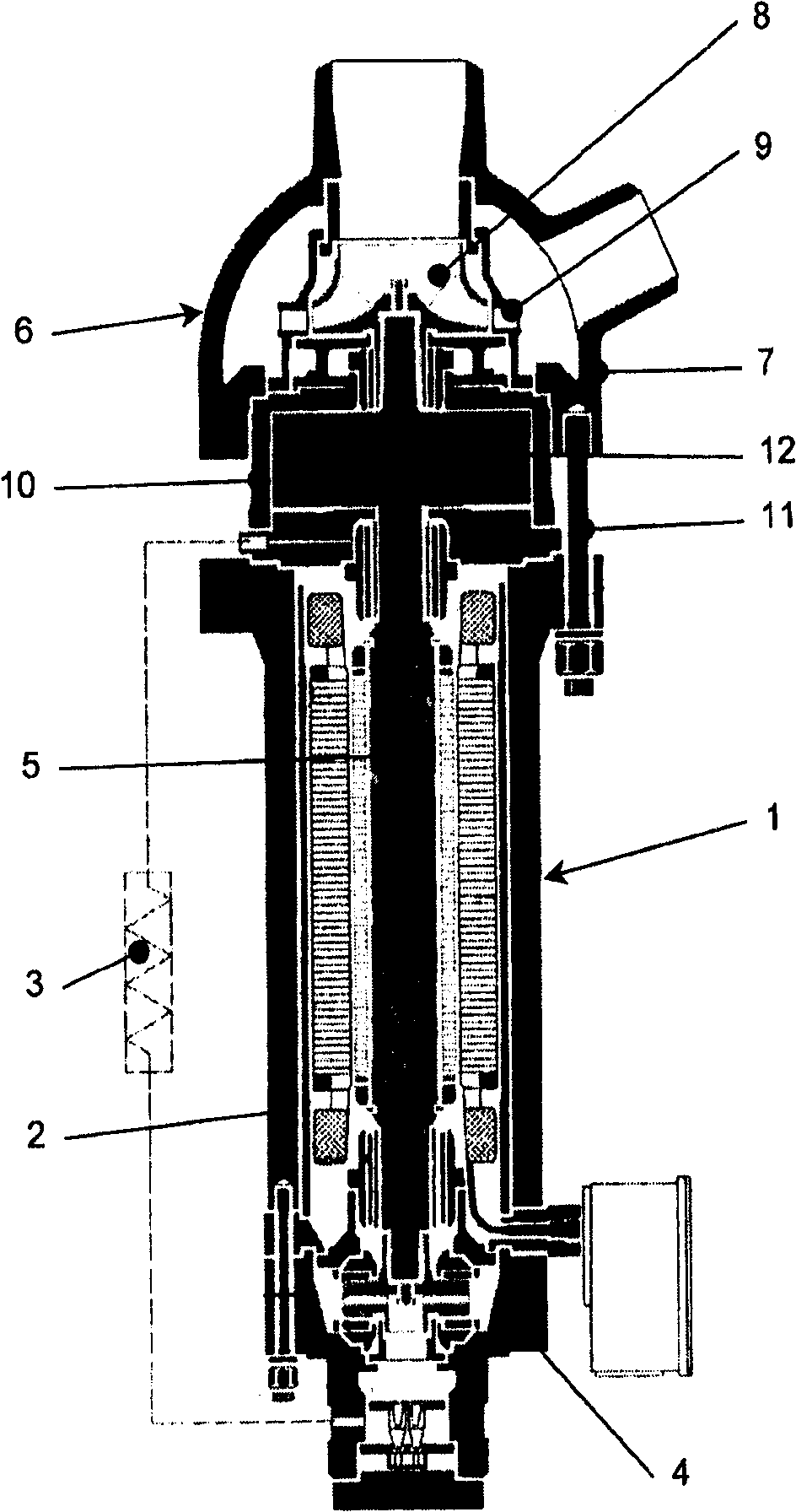

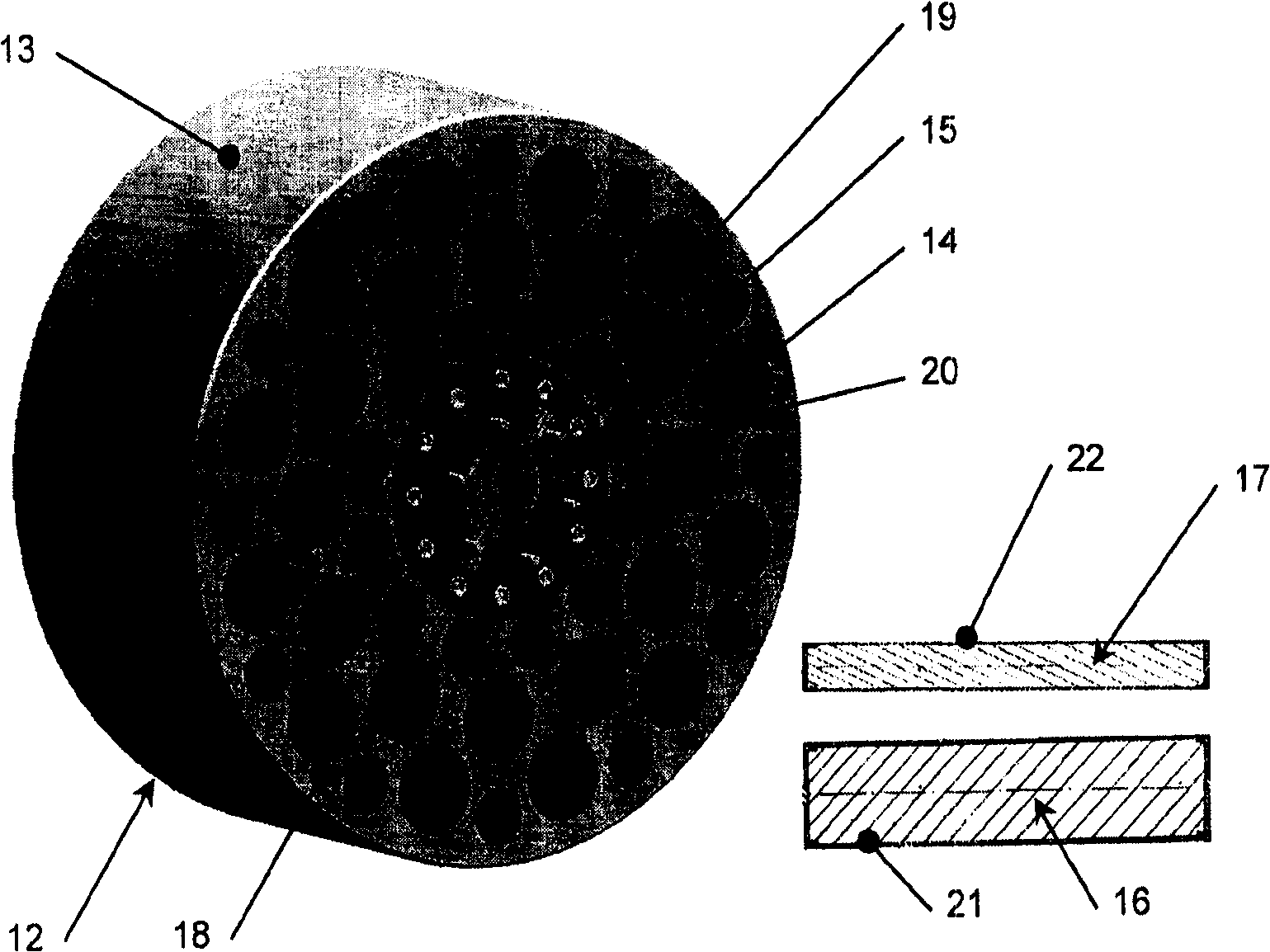

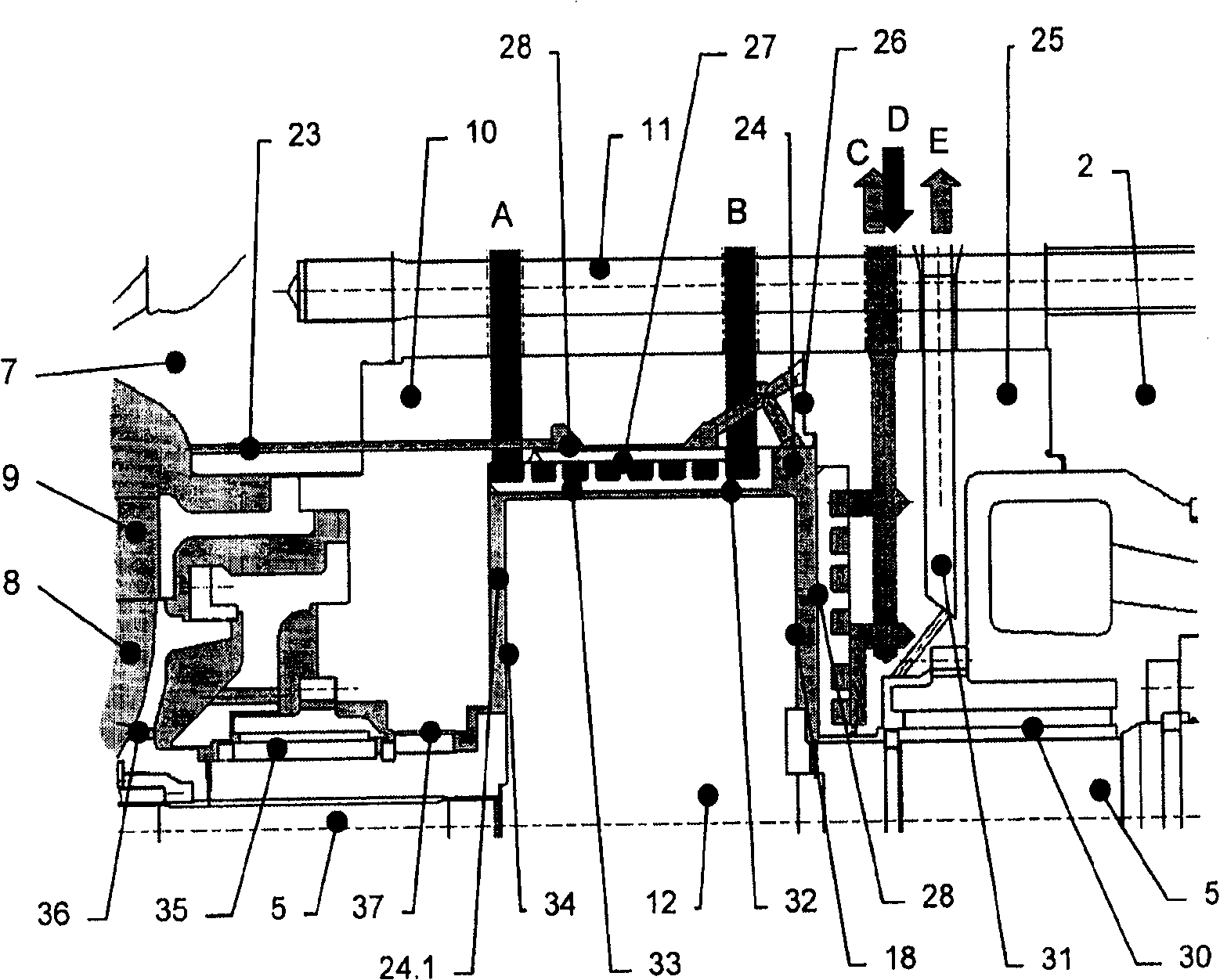

[0026] figure 1 A fluid-cooled motor 1 with a housing 2 is shown. The housing is designed as a pressure housing. The motor 1 is filled with fluid, and a high-pressure cooling system 3 is connected to the end of the motor to dissipate electrical power losses. A radial bearing and an axial bearing are arranged at the end 4 of the motor, wherein the axial bearing simultaneously serves as a delivery device for cooling water circulating in the motor and through the cooler 3 . The driving force of the motor acts on the shafting device 5 and transmits the torque to the pump 6 arranged coaxially with the electric motor 1 . The impeller 8 and the downstream guide 9 are arranged in the pump housing 7 , and the pump housing 7 is closed by a cover part 10 and connected to the housing 2 of the motor 1 via a tie rod 11 . A flywheel 12 is provided in the interior of the multi-part cover part 10 . The effect of its moment of inertia is to keep the shafting arrangement 5 to which the impel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com