Bionics method preparation of pure magnesium surface agustite coating

An apatite, pure magnesium technology, applied in coatings, medical science, bone implants, etc., can solve the problems of unsatisfactory biological properties, poor wear resistance and corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

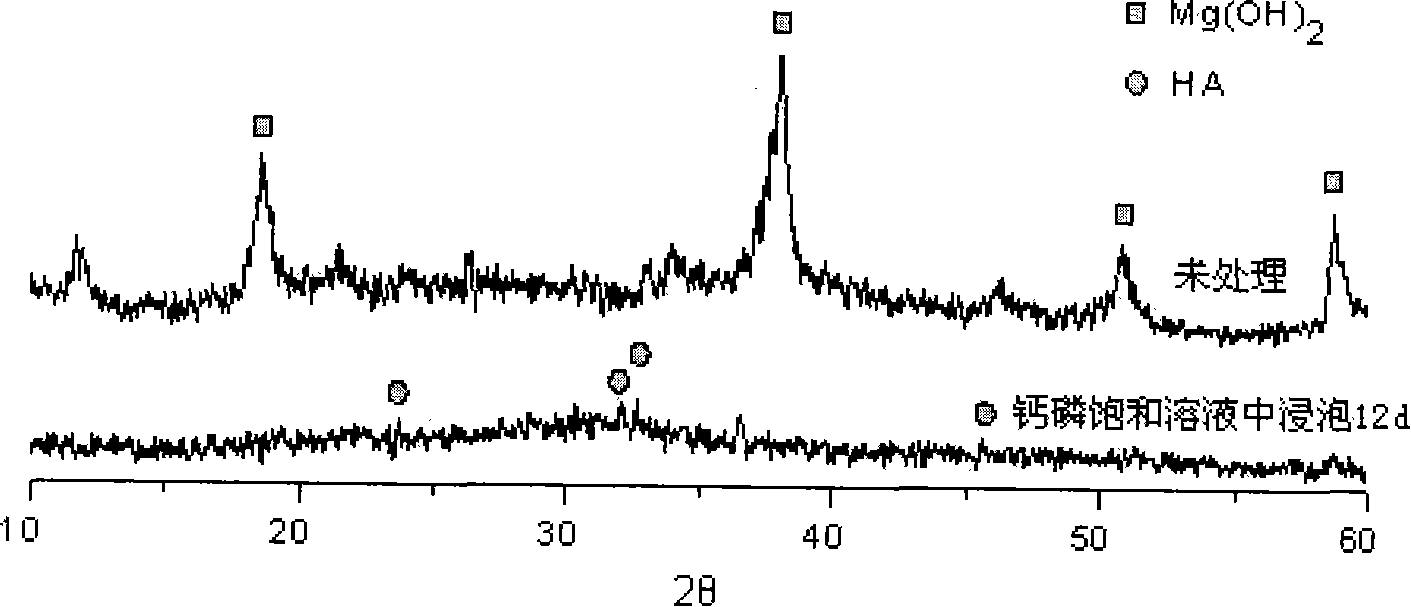

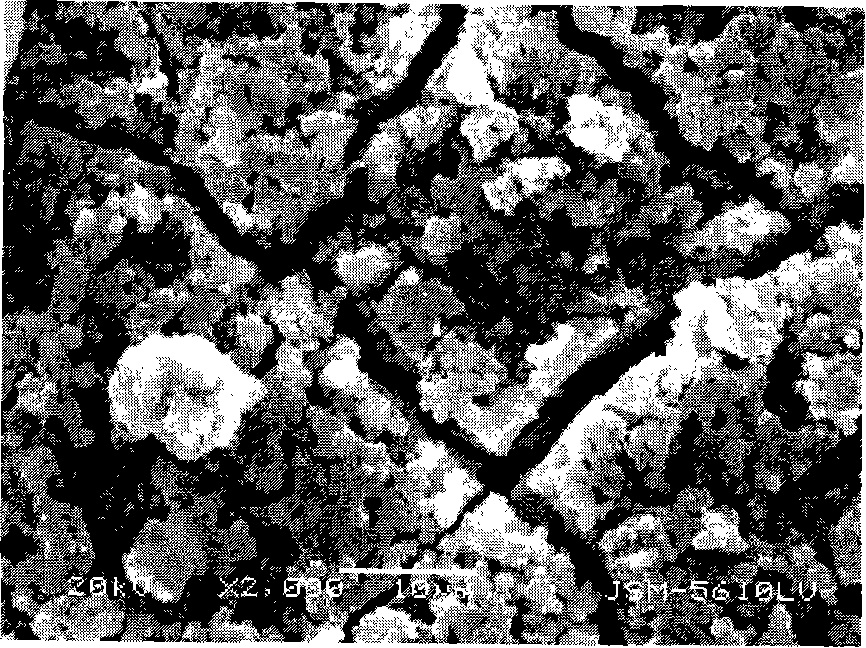

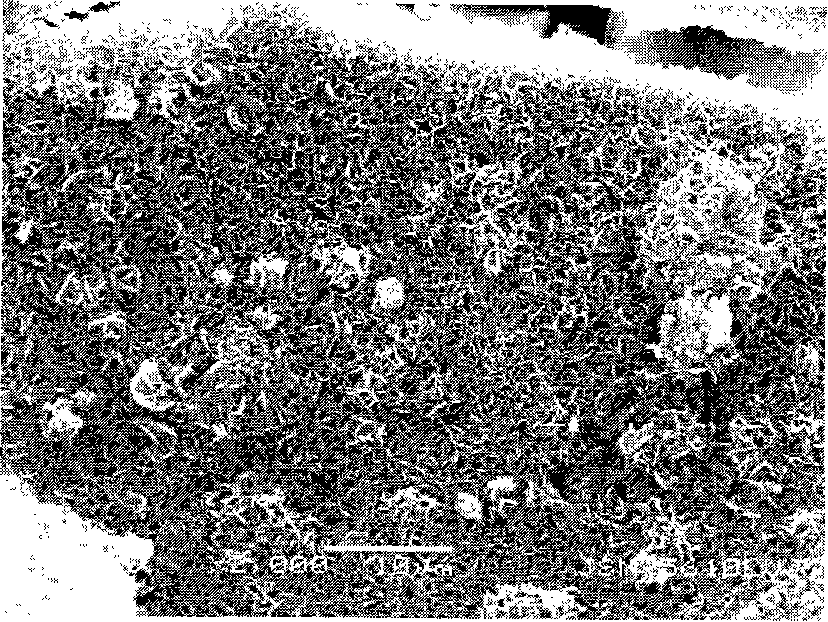

[0021] Embodiment 1 prepares apatite coating on pure magnesium surface

[0022] The preparation method steps are:

[0023] (1) Preparation and pretreatment of pure magnesium substrate, cutting the as-cast pure magnesium with a purity of 99.9% into volumes of 10×10×5mm 3 The sheet (substrate), and then use 200#, 400# water sandpaper to polish the surface. Ultrasonic clean the polished sample in distilled water, anhydrous acetone, and distilled water for 10 minutes in sequence, take it out after completion, and air dry it for later use;

[0024] (2) Immerse the pure magnesium substrate cleaned and dried in step (1) into 1mol / L HCl solution, take it out after acid etching for 3min, clean it in distilled water, and air-dry it for later use;

[0025] (3) Soak the pure magnesium substrate cleaned and dried in step (2) in 0.5mol / L NaOH solution at a temperature of 100° C., take it out after 30 minutes, clean it with distilled water, and air-dry it for later use;

[0026] (4) Pre-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com