Apparatus and method for testing optical glass homogeneity

A technology of optical glass and testing equipment, which is applied in measuring equipment, material analysis through optical means, scientific instruments, etc., can solve the problems that errors cannot be eliminated and the amount of errors is large, and achieve the goal of reducing uneven air distribution and disturbance The effect of reducing quality requirements and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

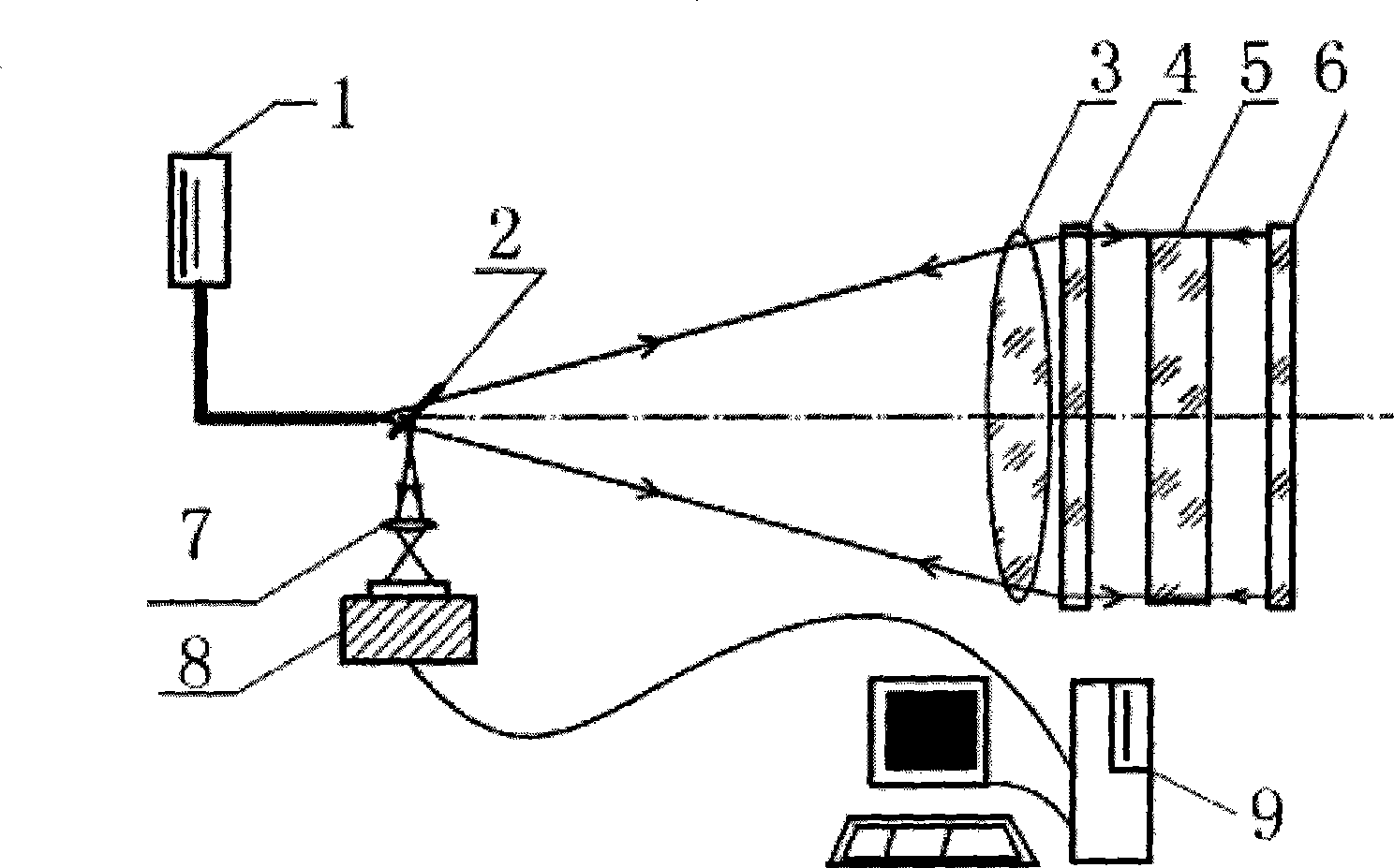

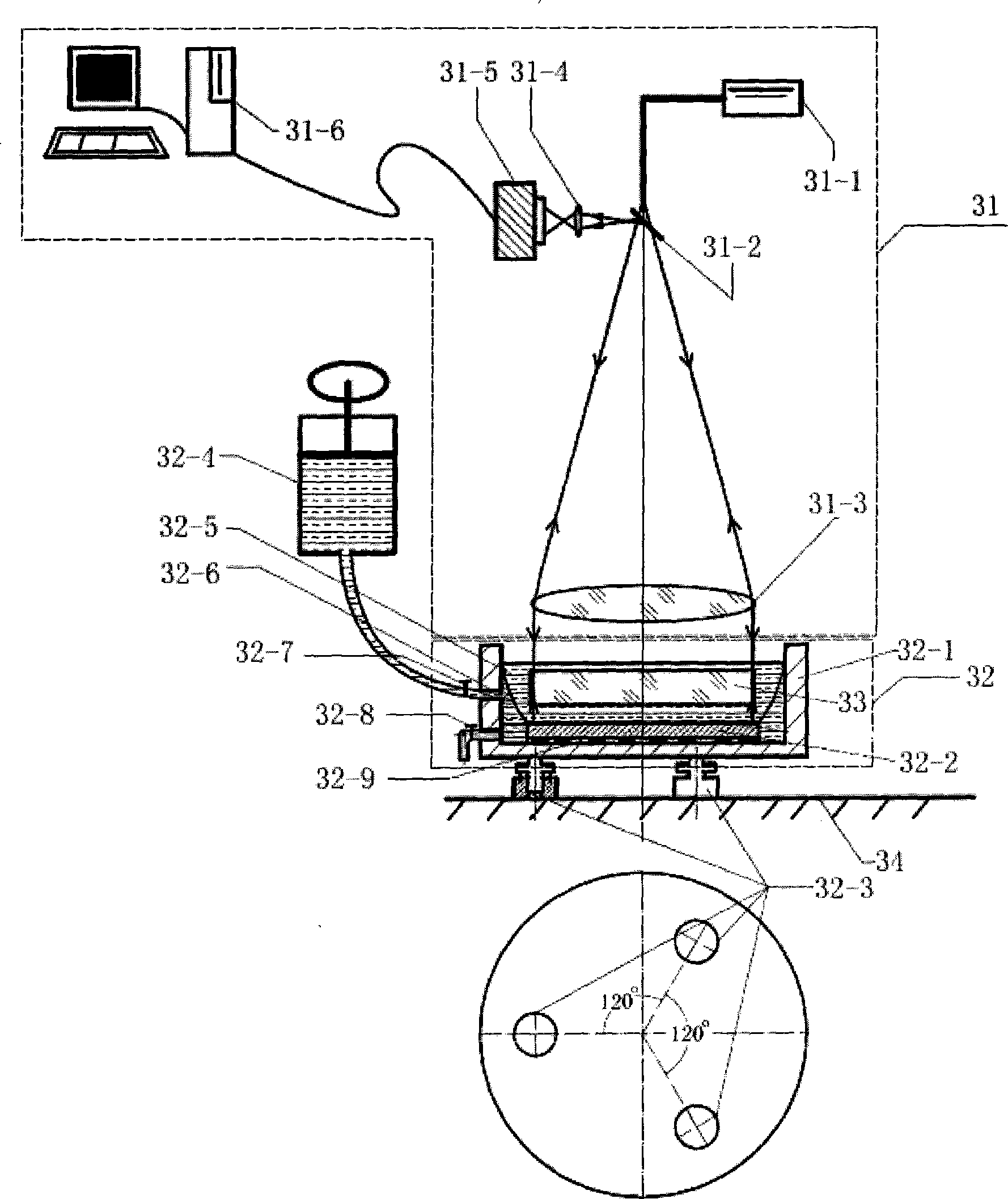

[0043] See first image 3 , image 3 It is a schematic diagram of the optical glass uniformity test device of the present invention. It can be seen from the figure that the testing device for the uniformity of optical glass of the present invention includes:

[0044] The interferometer and data acquisition system 31 consists of a laser 31-1, a beam splitter 31-2, a beam expander objective lens 31-3, an imaging objective lens 31-4, a CCD camera 31-5 and an image acquisition processor 31-6. The positional relationship is: the laser beam emitted by the laser 31-1 passes through the beam splitter 31-2, is collimated by the beam expander lens 31-3, and irradiates the optical glass 33 to be measured in the liquid tank 32-1. The beam expander objective lens 31-3 collects the reflected light beam from the direction of the liquid tank 32-1 and is reflected by the beam splitter 31-2, which is imaged by the imaging objective lens 31-4, captured by the CCD camera 31-5 and sent to the image co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com