Composite board for heat sinking and forming method thereof

A composite board and flat panel technology, applied in circuit substrate materials, cooling/ventilation/heating transformation, printed circuit, etc., can solve problems such as difficulty in coping with local heating and unsatisfactory cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the present invention will be described in detail with reference to the accompanying drawings.

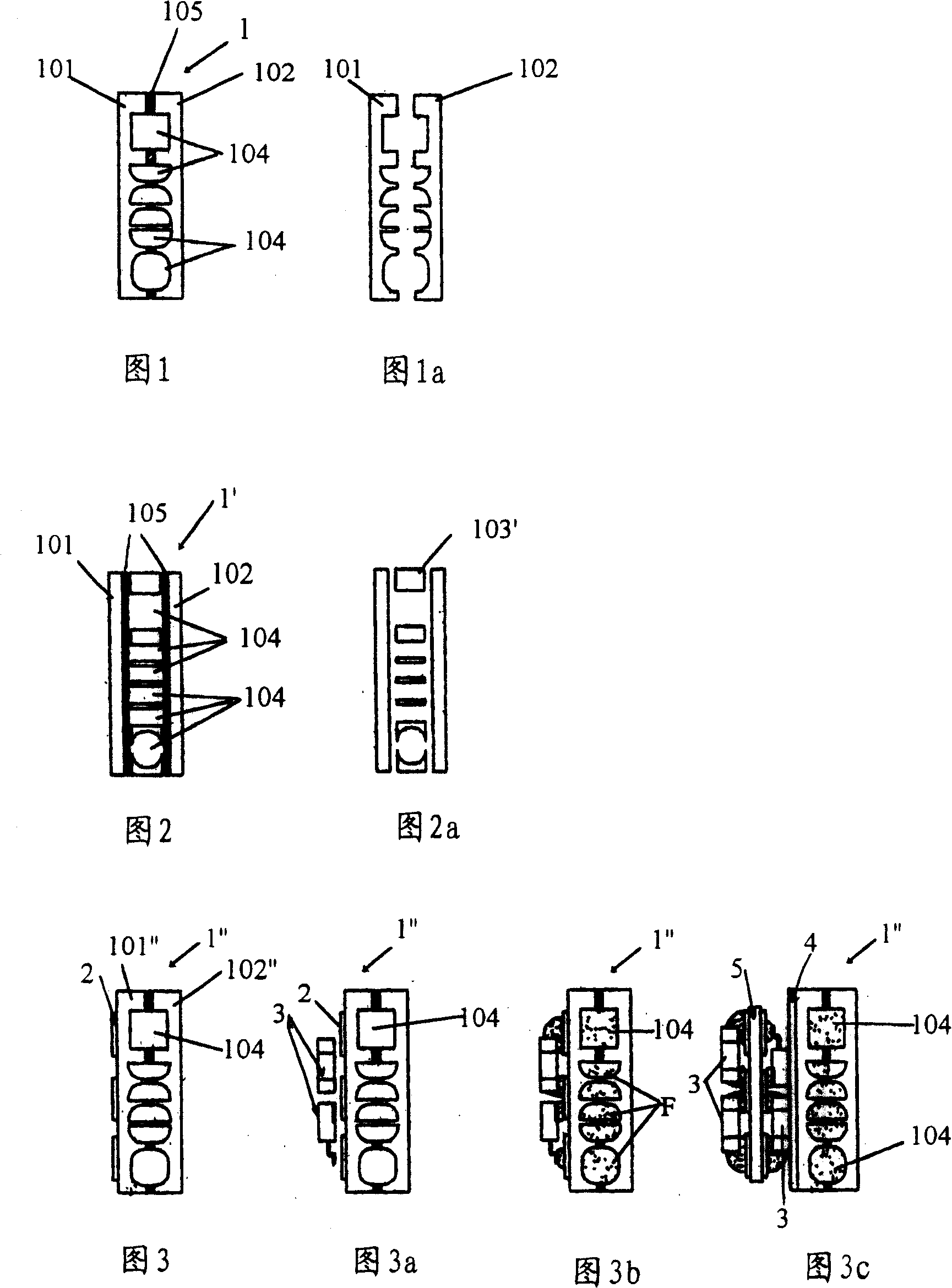

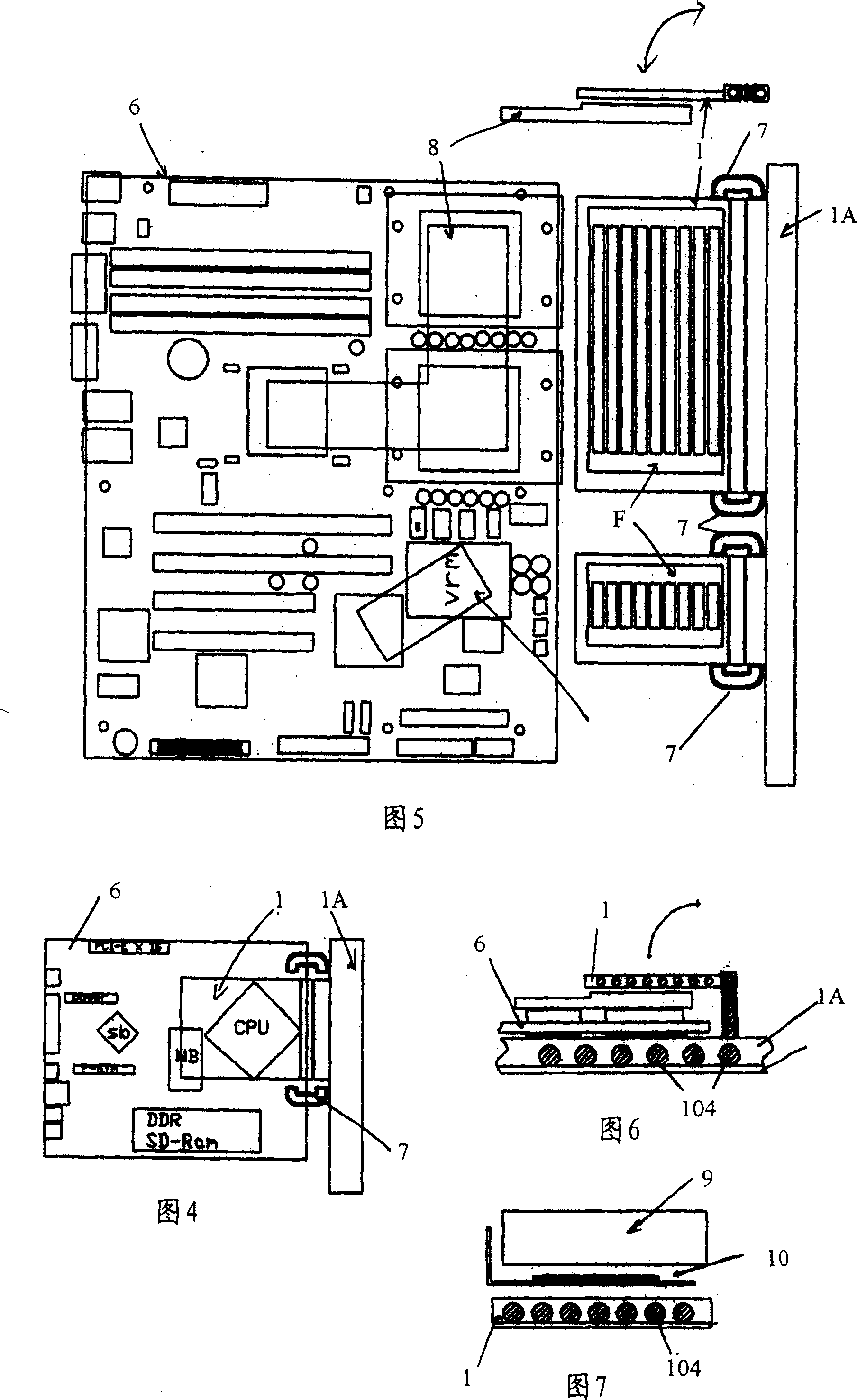

[0028] Fig. 1, 1a is the composite plate 1 that is formed by two flat plates 101, 102, one surface of which is left blank by grinding or pre-molding method, and then such a plate is passed through a sealing layer such as welding with one surface left empty 105 are connected together to form a plurality of grooves or passages 104 for the heat transfer liquid to flow through. The material of the plate can be P.C., glass, metal, heat-resistant plastic, even marble, and wood (with waterproof treatment in the middle). Because it is combined, it can be called a synthetic board. Corresponding grooves are formed on the opposite sides of the two plates, and when they are engaged, a correspondingly shaped channel 104 is formed through which the cooling liquid can circulate. The cooling liquid can be hydrocarbon oil (such as OPTICOOL's ALPA OIL), water and alcohol mixture or o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com