Indirect steam scouring method

A secondary steam, pure technology, applied in chemical instruments and methods, separation methods, multi-effect evaporation, etc., can solve the problems of strong corrosion and waste of equipment, and achieve the effect of avoiding pollution and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

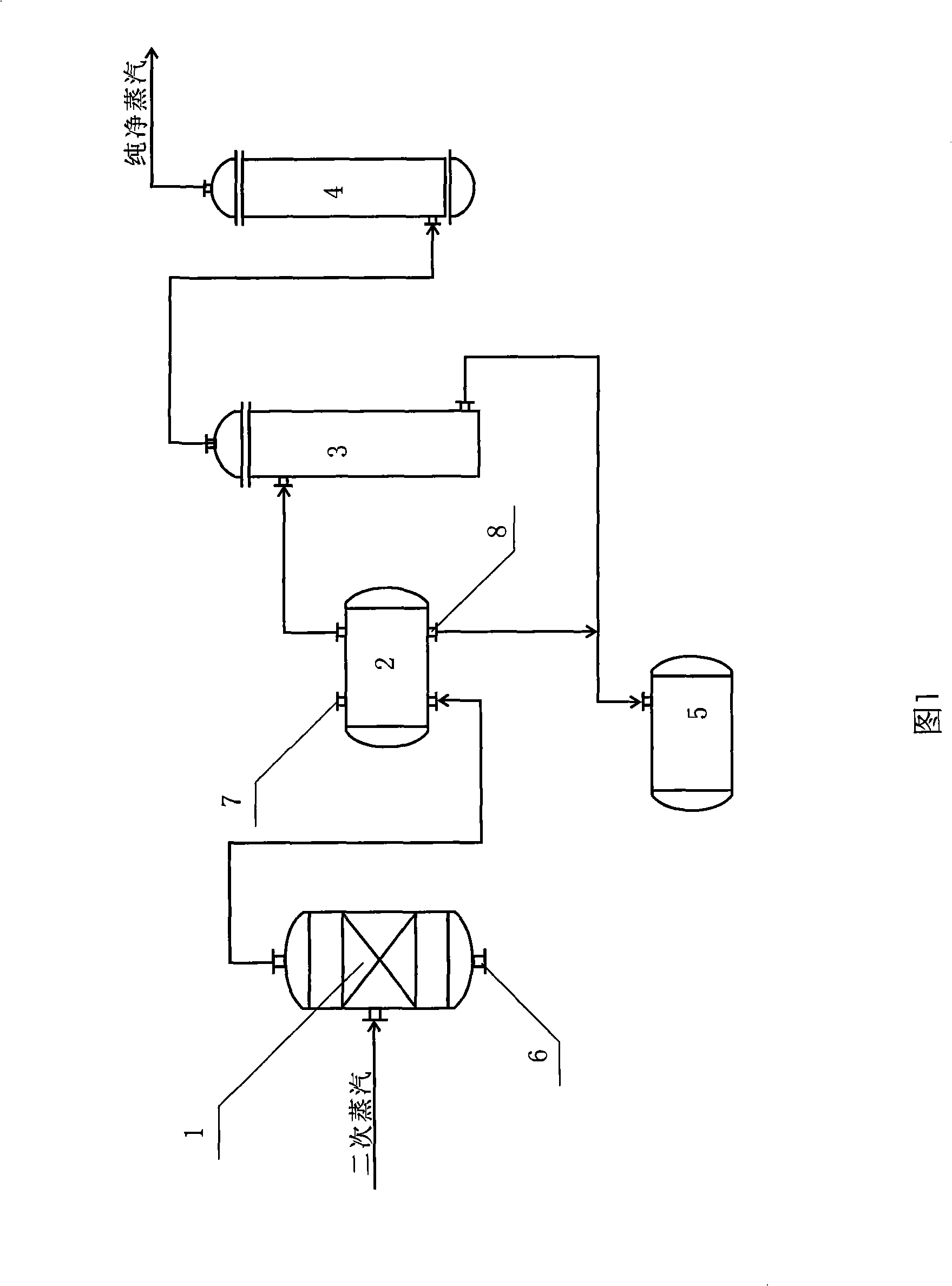

[0017] As can be seen from the accompanying drawings, the present invention is to purify, neutralize, and vapor-liquid separate the secondary steam produced by multi-effect evaporation of brine, and then obtain pure secondary steam with a pH value of 7-8.3 through a cleaning process. , neutralization, vapor-liquid separation, and cleaning procedures include a foam catcher, a neutralization tank, a separator, and a water washing tower. The specific method includes: the secondary steam enters the foam catcher, and the brine droplets entrained in the secondary steam are mixed with phase separation, the purified secondary steam enters the neutralization tank, and the separated brine droplets are discharged through the brine discharge port set at the bottom of the mist catcher;

[0018] The secondary steam that enters the neutralization tank meets the lye that is sprayed into the alkali-adding port provided by the neutralization tank, neutralizes the secondary steam, and then enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com