Humidifying tower tail structure

A humidification tower and screw conveyor technology, applied in the direction of solid separation, chemical instruments and methods, electrostatic effect separation, etc., can solve the problems of low dust collection efficiency of humidification tower, high connection equipment height, high outlet flue gas temperature, etc. Achieve the effect of facilitating the overall layout, increasing the residence time and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

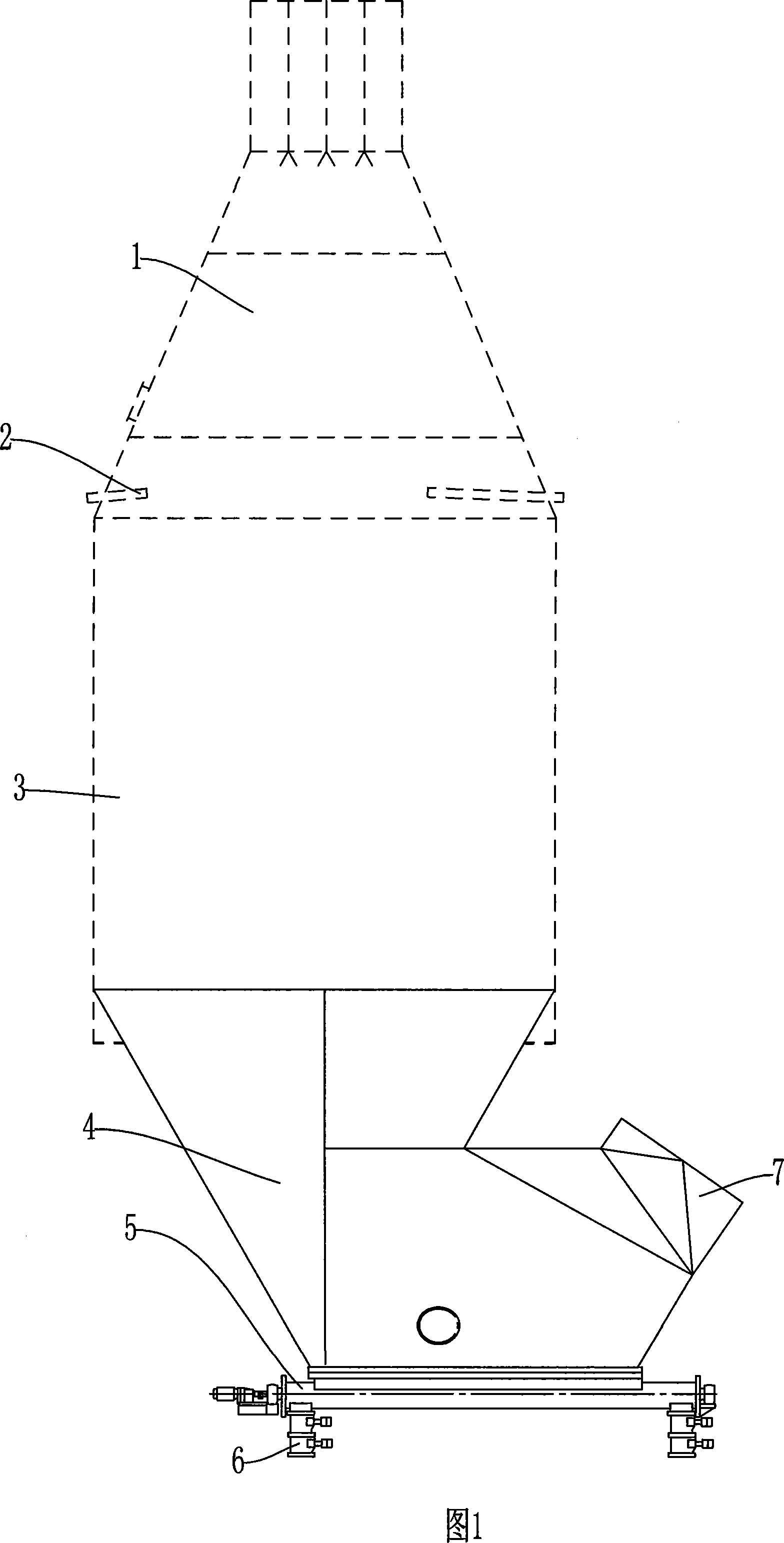

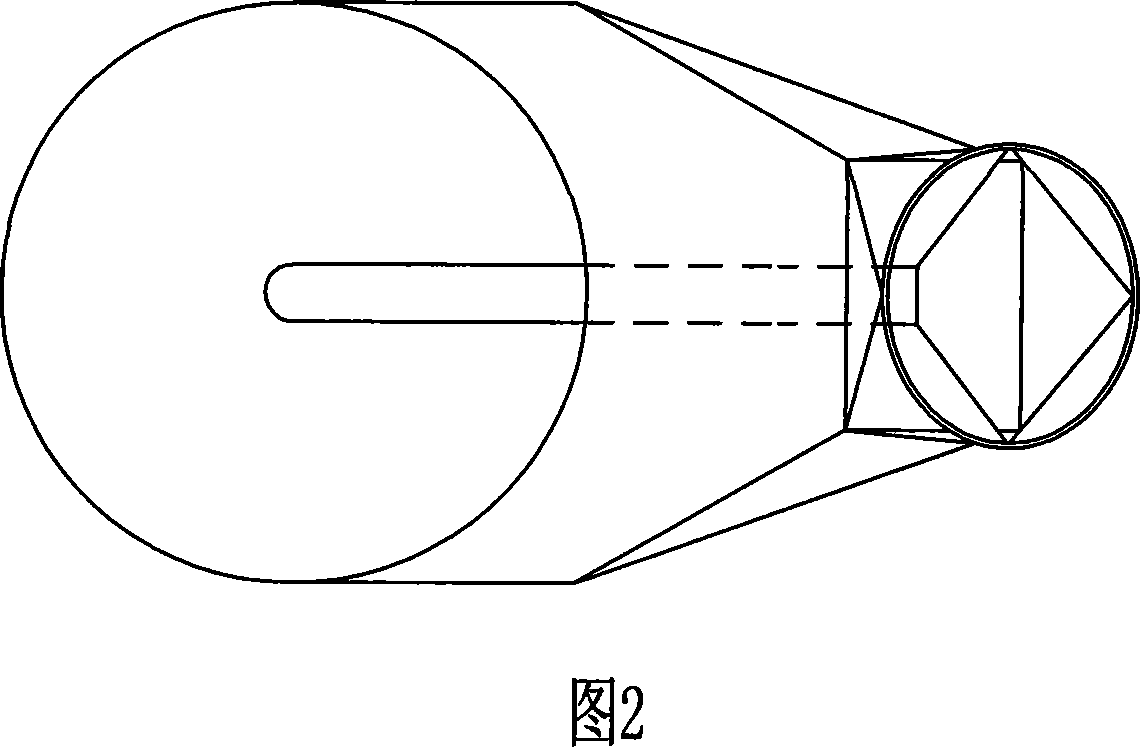

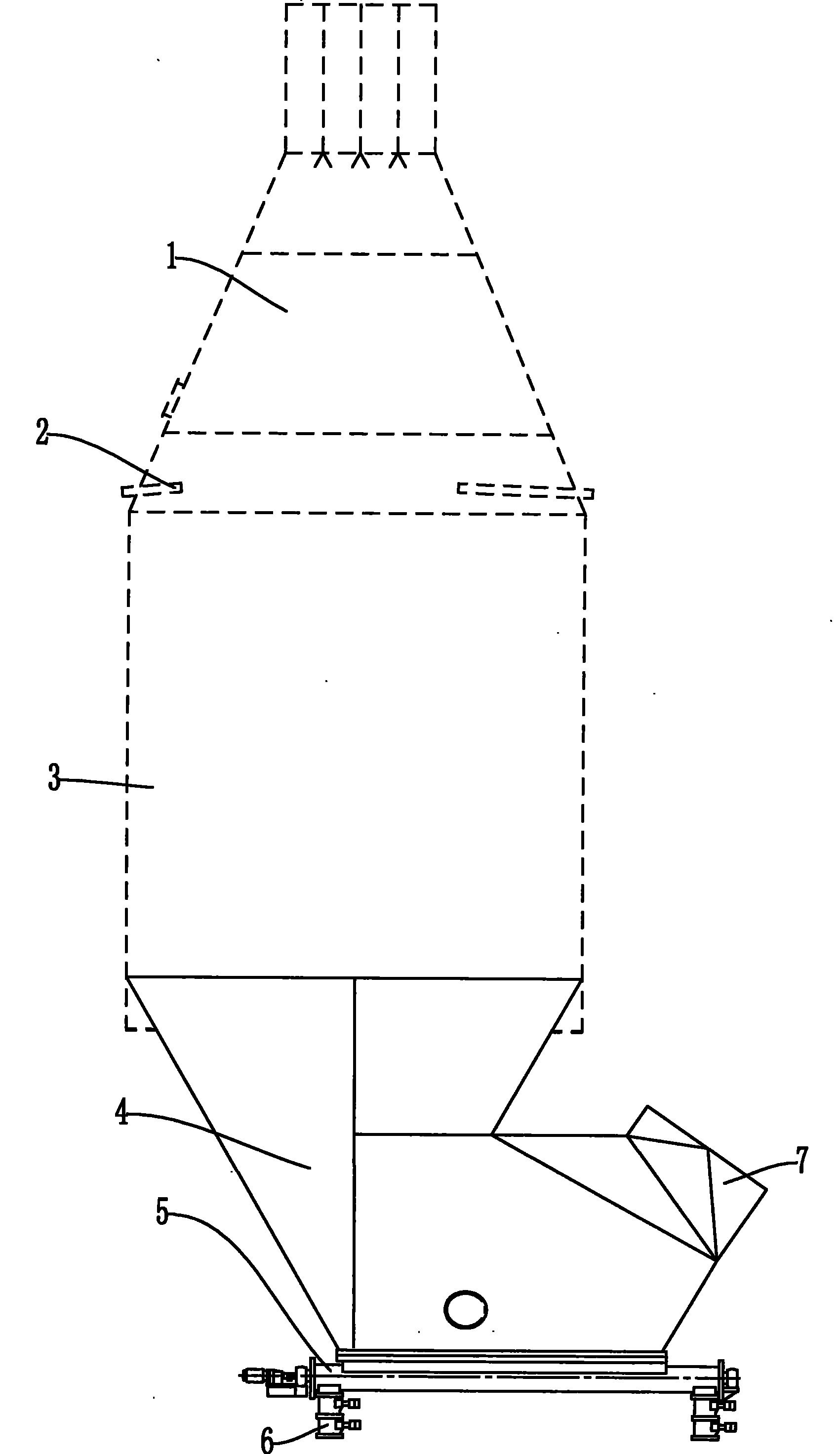

[0013] figure 1 , 2 Among them, the tail device 4 of the humidifying tower is in the shape of a boat (i.e. the boat-shaped tail), the screw conveyor 5 is arranged on the bottom of the ship, one side of the bottom of the ship is basically on the axis of the humidifying tower, and the outlet 7 is arranged on the side of the ship on the other side of the boat-shaped device . The humidification tower includes a tower body 3, one side of the tail device 4 of the humidification tower is connected to the lower part of the tower body 3, the upper part of the tower body 3 is connected to a water spray system 2, and the upper part of the water spray system 2 is connected to the air inlet 1. The air inlet 1 is an inverted cone with a slope, and a porous gas distribution plate is installed inside to improve the air distribution condition. The screw conveyor 5 is moved from directly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com