Roller train for conveying thin sheet panel and method for chemical treatment thereby

A technology of roller group and roller, which is applied in liquid processing of printed circuit, simultaneous processing of multiple printed circuits, furnace components, etc. It can solve the problems of fixed roller and damage to thin substrate, etc., and achieve the effect of smooth and continuous wet chemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention can be explained in more detail with reference to the accompanying drawings.

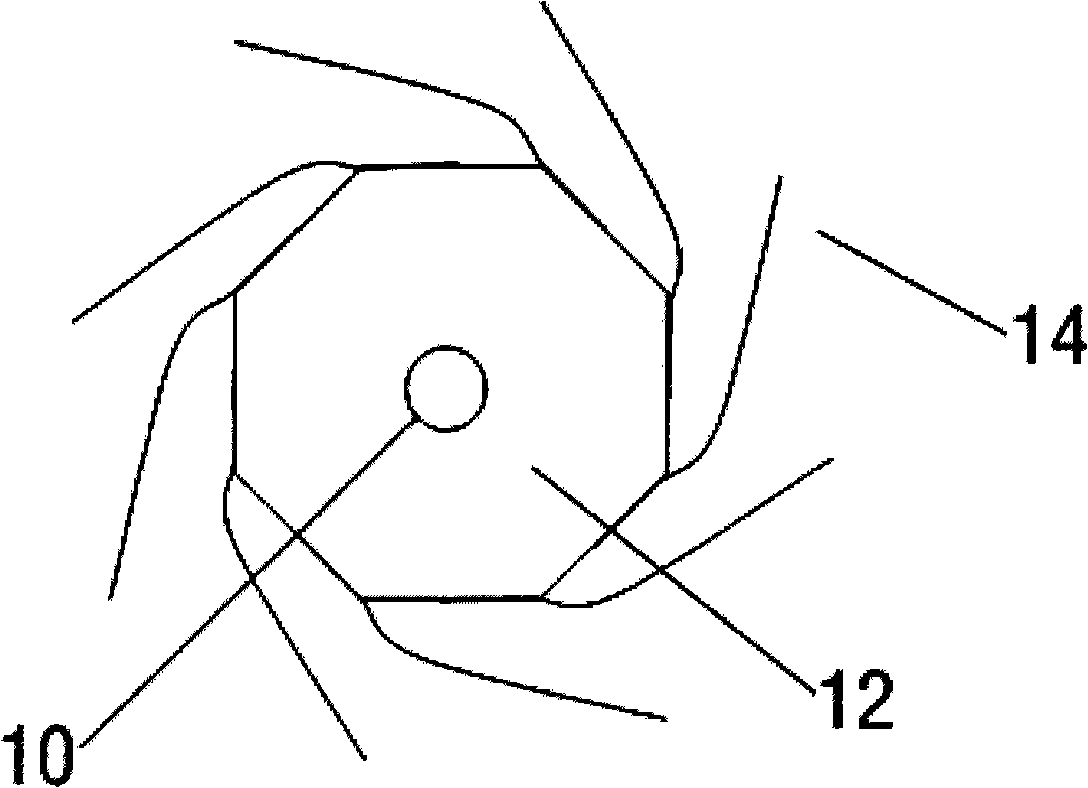

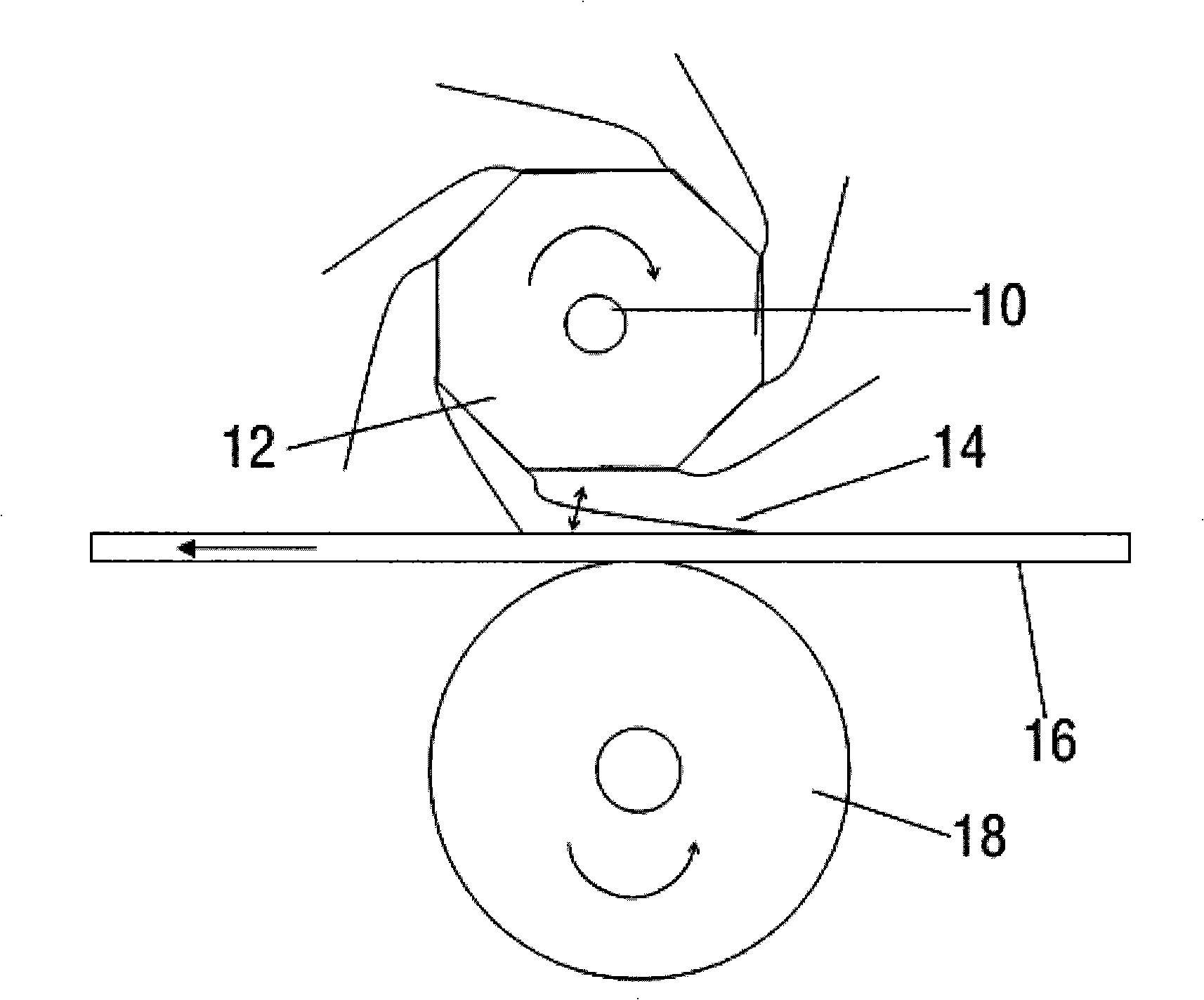

[0029] figure 1 It is a schematic diagram of the first embodiment of the roller set for conveying thin substrates of the present invention, in which the elastic piece of the upper roller is fixed at one end on the roller with a non-circular section.

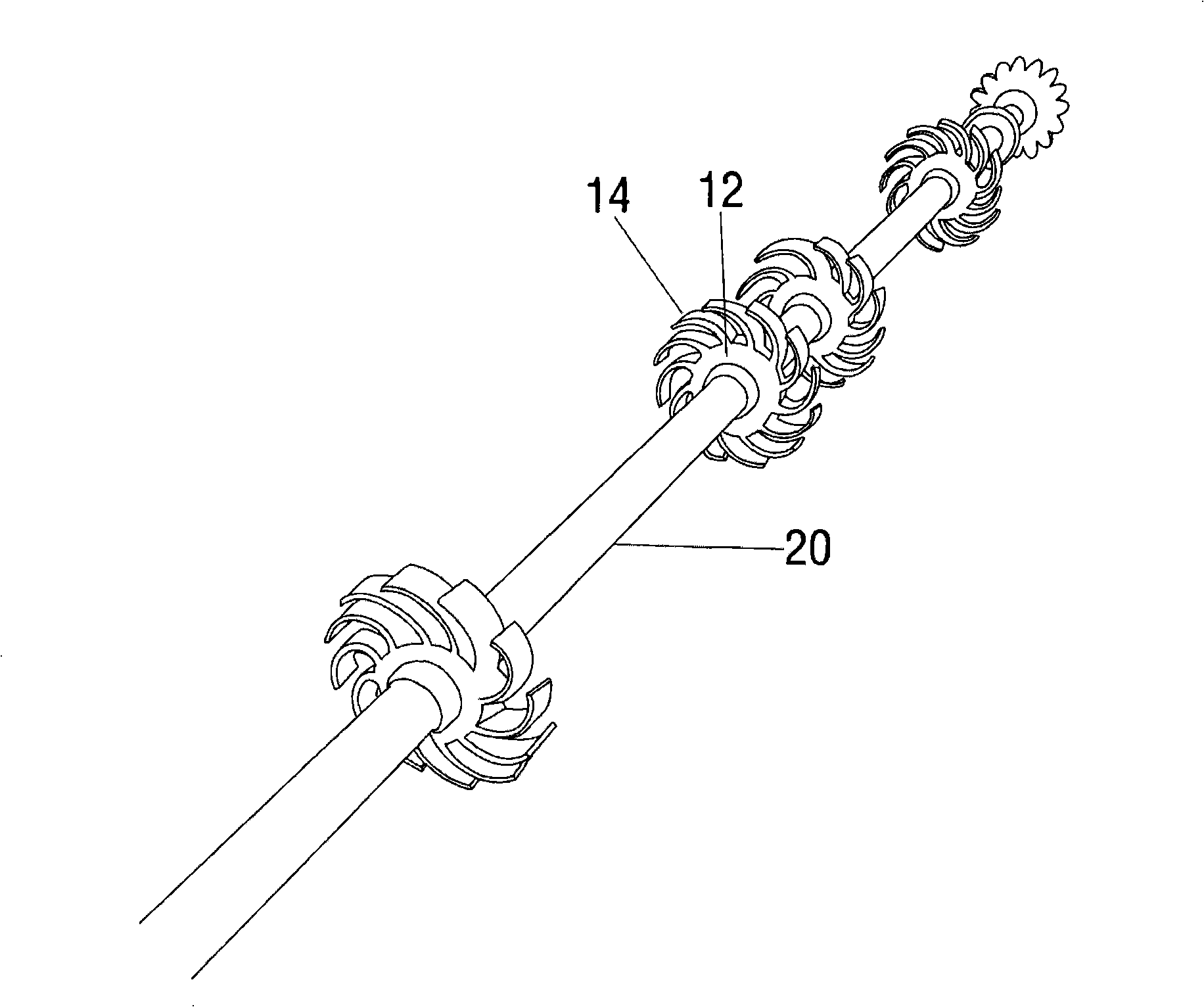

[0030] Such as figure 1 As shown, in the roller set of the present invention, the upper roller includes a fixed roller 12 and an elastic sheet 14, wherein the cross section of the fixed roller 12 is polygonal, and a series of elastic sheets 14 are installed on its periphery. Small hole 10 is arranged in the fixed roller 12 center, is used for this upper roller is fixed on the transmission shaft 20 (referring to image 3 ). The upper roller and the corresponding lower roller can rotate clockwise and counterclockwise at the same linear speed driven by their respective shafts.

[0031] Elastic piece 14 is configured as one end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com