Hydraulically driven and controlled stage hanger rod system

A control system and boom technology, used in portable lifting devices, entertainment devices, entertainment and other directions, can solve problems such as easy vibration damage to machinery, decreasing driving torque, complex transmission system, etc., to achieve stable work, large output torque, controllable high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

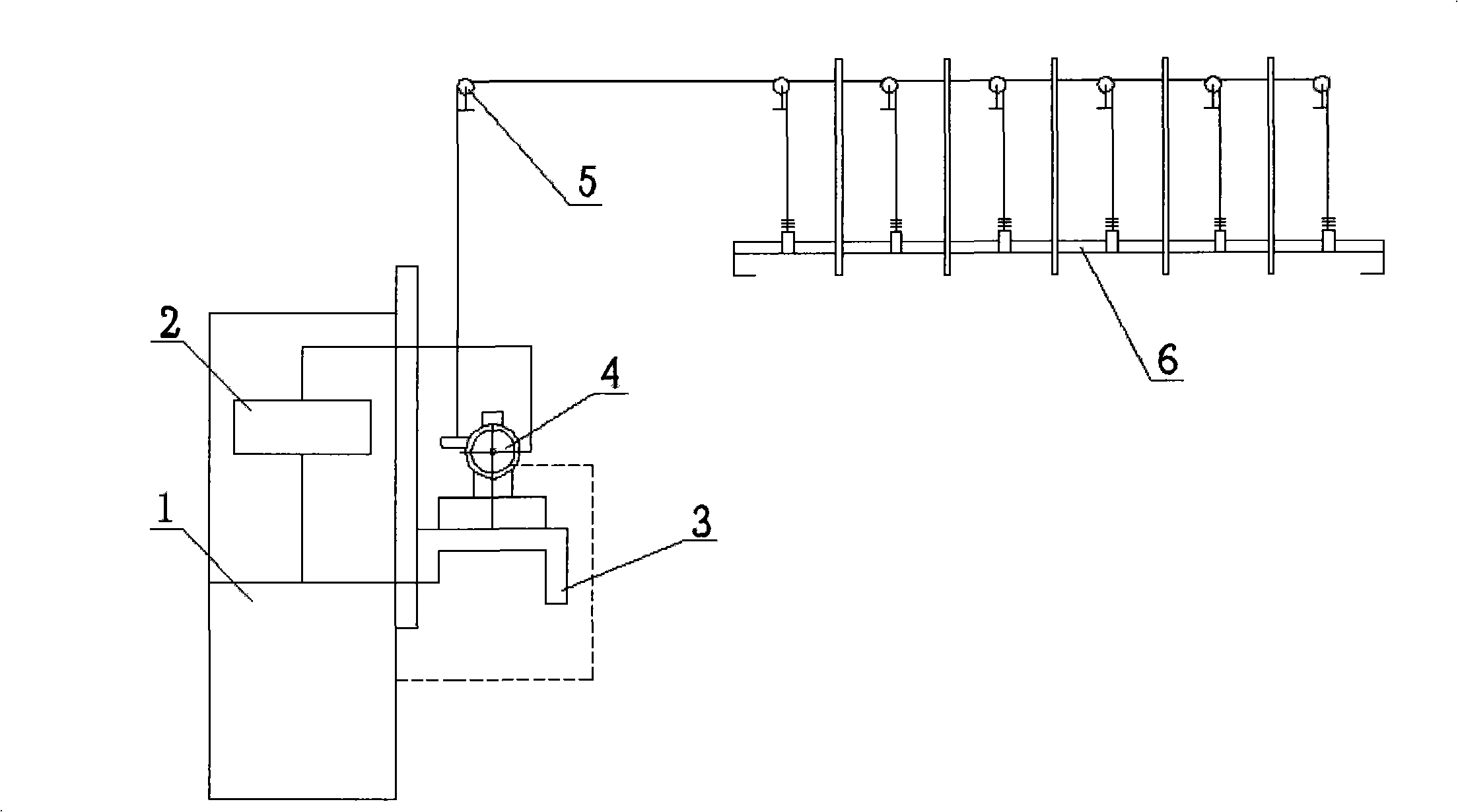

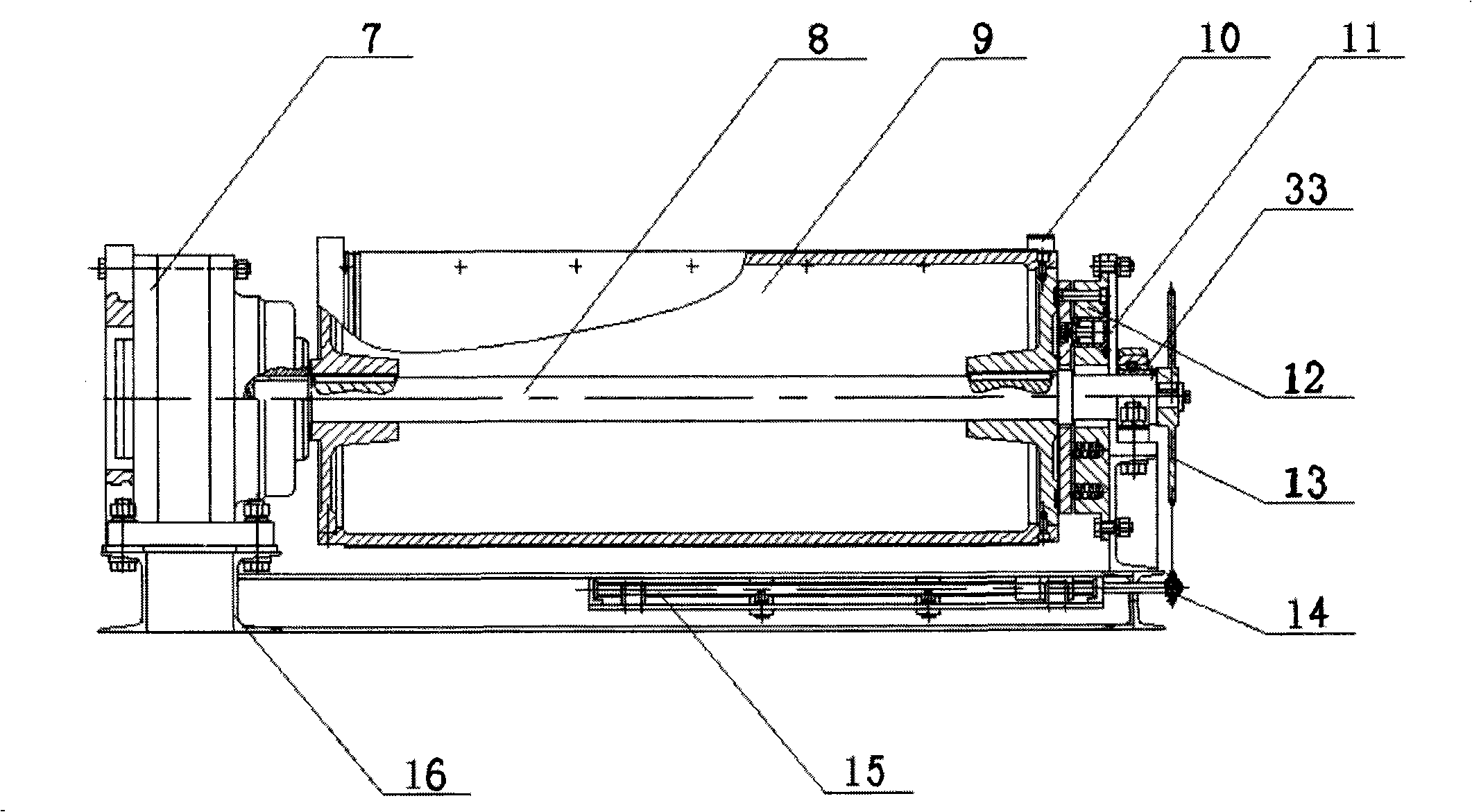

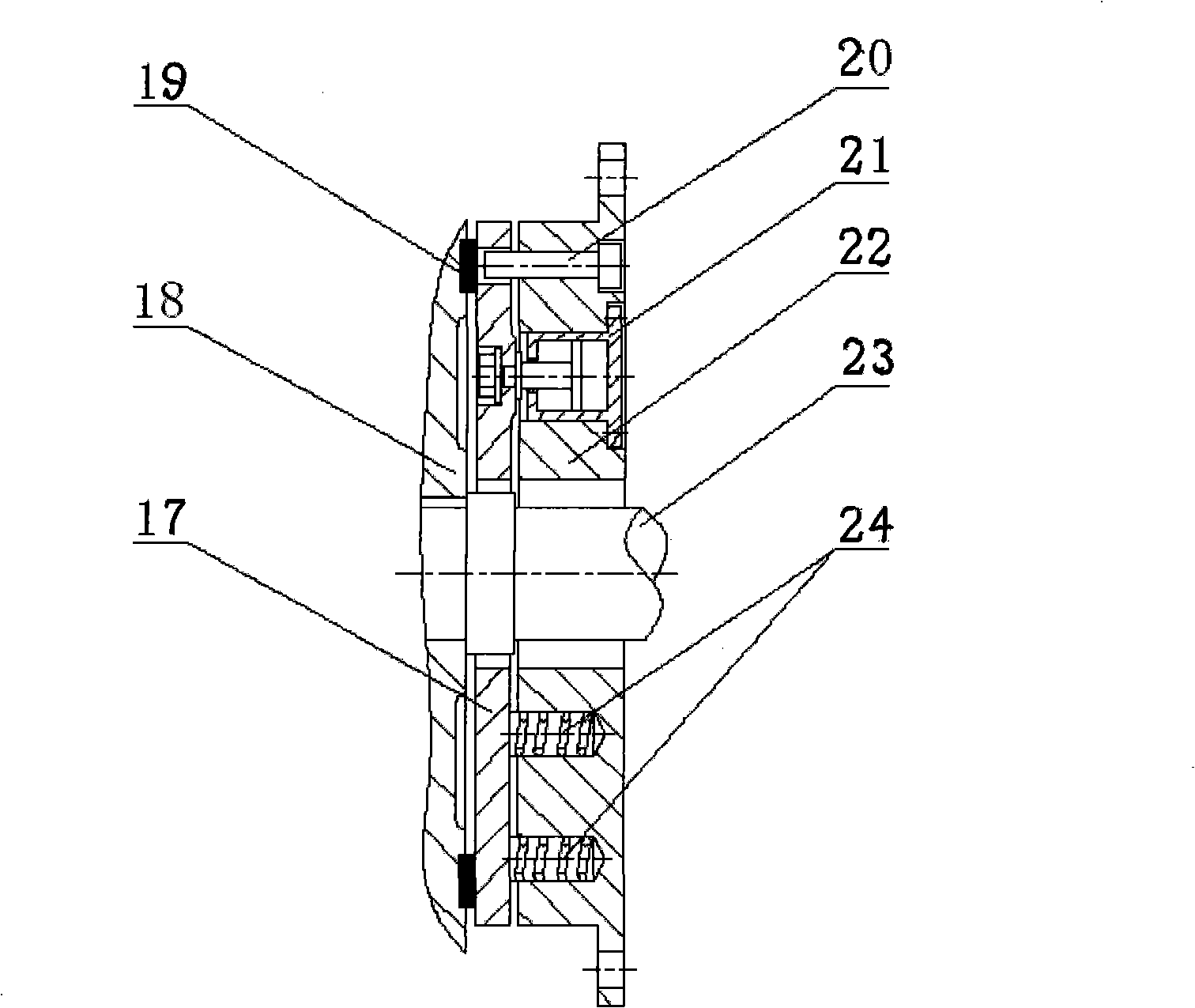

[0019] Such as figure 1 , 2 , 3, and 4, the described a hydraulically driven and controlled stage boom system includes a pulley system 5, a boom 6 and a driving machine 4 arranged on the flyover 3, the present invention is characterized in that: Said flyover 3 is provided with a pumping station 1 and a control system 2 connected with the driving machine 4, the driving machine 4 includes a base 16, the base 16 is provided with a hydraulic motor 7, and one end of the transmission shaft 8 is connected to the power of the hydraulic motor 7. The output ends are connected, the drum 9 is installed on the transmission shaft 8, and the position holder 10 is arranged on the drum 9; the other end of the transmission shaft 8 is installed on the bracket 11 at the end of the base 16 through the outer spherical ball bearing 33 with a seat, and the bracket 11 is provided with a hydraulic brake 12 at the position corresponding to the end face of the drum 9, and the end of the drive shaft 8 ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com