Master batch and fibre as well as manufacturing method thereof

A manufacturing method and masterbatch technology, applied in the field of fibers, can solve the problems of low antibacterial effect of fibers, lack of durable fiber functions, and single functional fiber functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

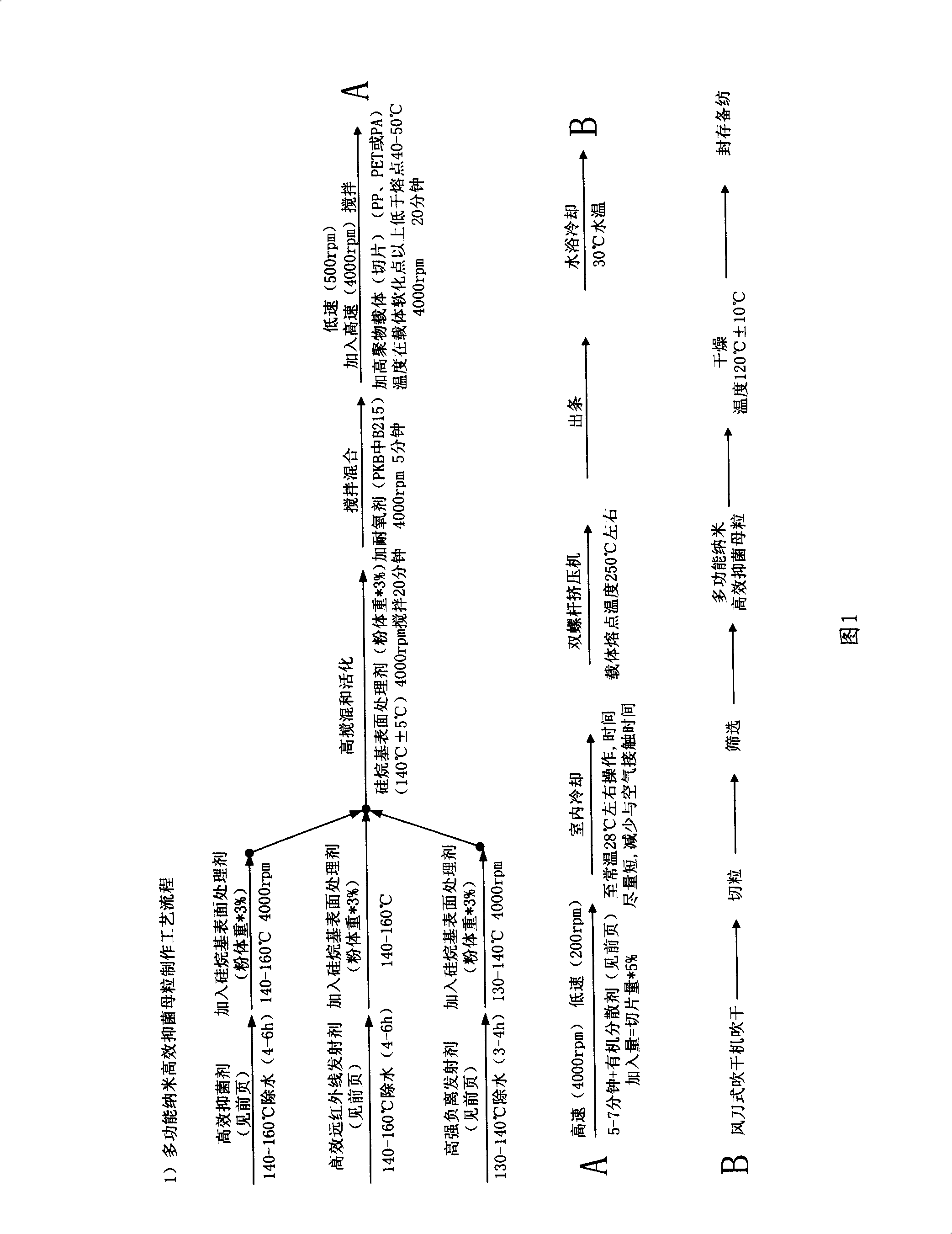

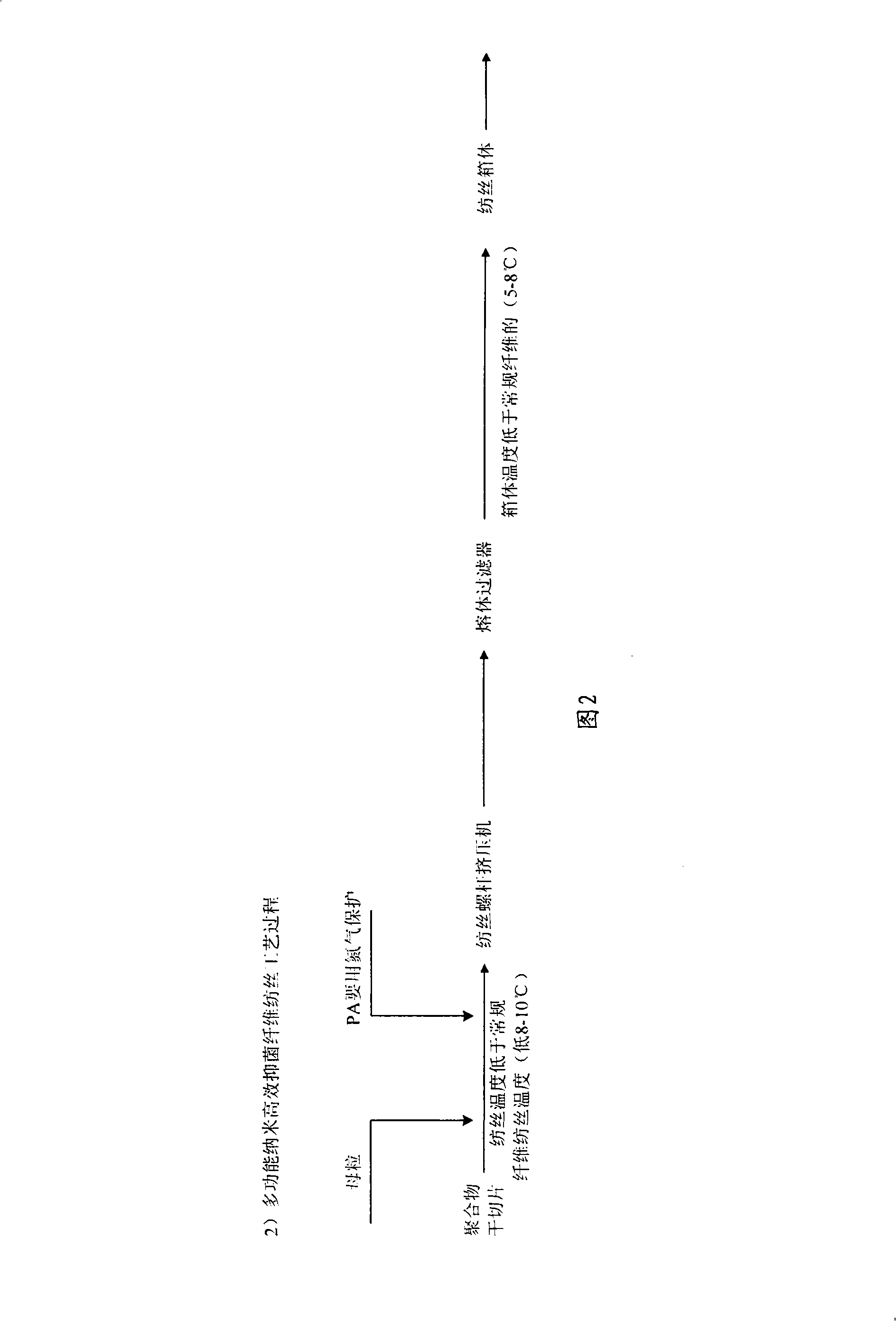

[0033] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0034] ●The combination of three functional inorganic salt formulas added to the fibers of this solution:

[0035] 1. Far-infrared emitter: nano-scale zirconia accounts for 45% of the weight of the far-infrared emitter, titanium dioxide accounts for 55% of the weight of the far-infrared emitter, and a silane-based coupling agent (accounting for 3% of the weight of the above substances);

[0036] ②Anion launcher: nano-scale tourmaline powder accounts for 75% of the weight of the negative ion launcher, titanium dioxide accounts for 25% of the weight of the negative ion launcher, and a silane-based coupling agent (accounts for 3% of the weight of the above substances);

[0037] 3. High-efficiency bacteriostatic agent: Ag+ accounts for 6.5% of the weight of the efficient bacteriostatic agent, 93.5% of titanium dioxide acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com