Wet vapor level suction dehumidifier for steam turbine

A dehumidification device and steam turbine technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as high steam humidity, corrosion of moving blades, and reduced steam power efficiency, so as to slow down the corrosion rate and improve operation safety. , the effect of eliminating hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

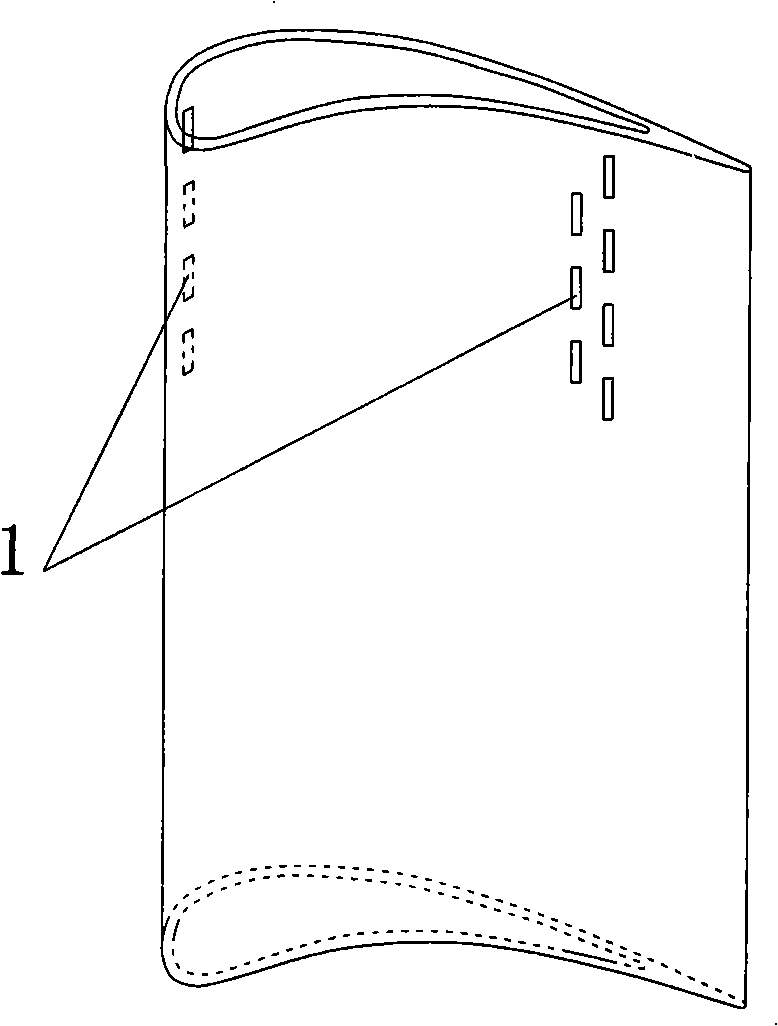

[0018] refer to figure 1 , the inner arc surface and the back arc surface of the stator blade are provided with a suction gap 1, the suction gap of the inner arc surface of the stator blade is set in the rear area of the inner arc surface of the upper half, and the suction gap is two adjacent vertical columns. Open to the strip; the suction slot on the back arc of the stationary blade is set in the front area of the upper half of the back arc, and the suction slot is a row of vertical strip openings. Since the liquid film or stream on the surface of the vane flows upward through the centrifugal action of the vane steam, the lower half of the vane surface accumulates relatively less liquid, so the lower half of the vane surface does not need to open a suction gap.

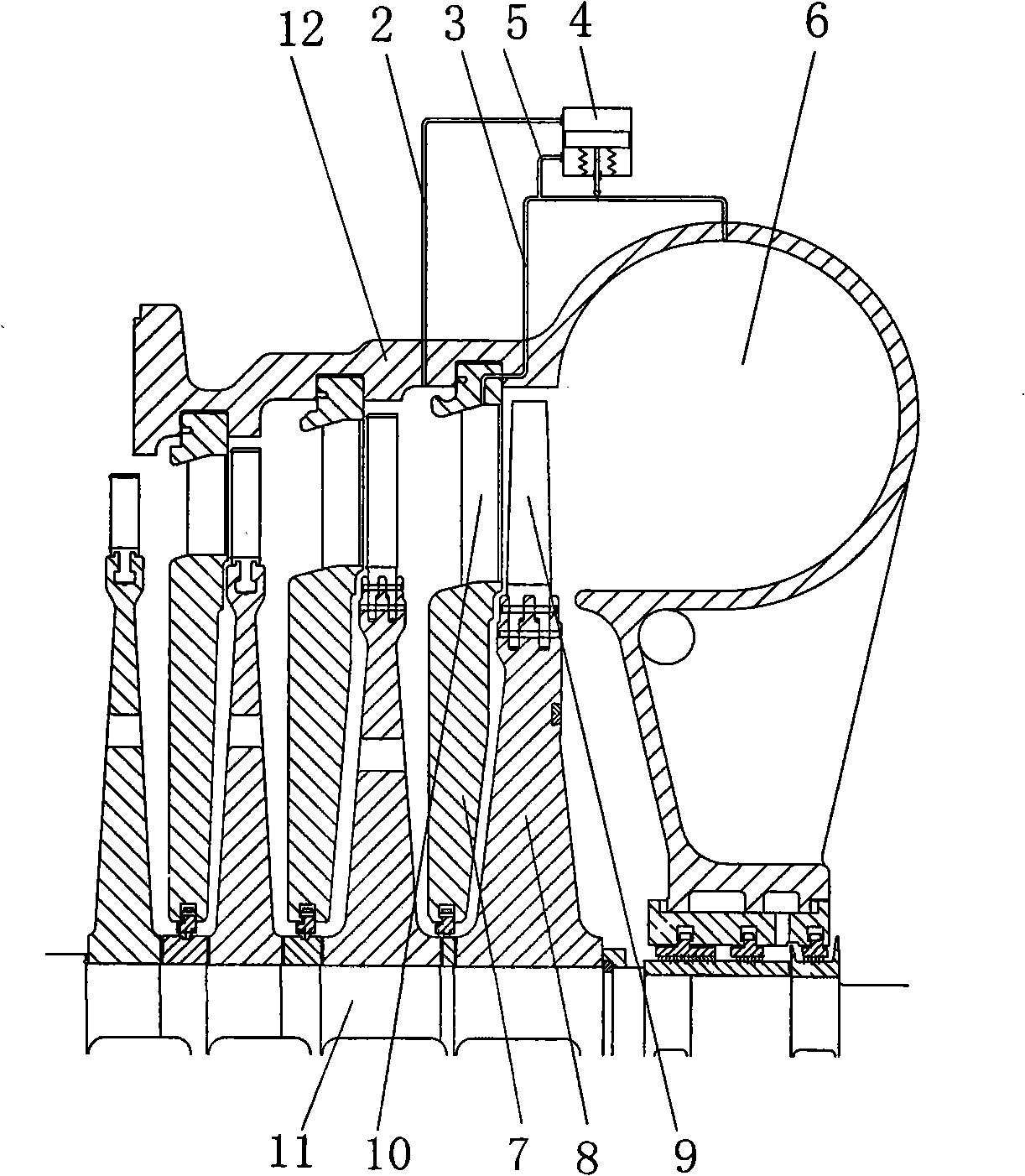

[0019] see figure 2 , the wet steam stage in this embodiment selects the last stage of the steam turbine for illustration. A main shaft 11 is arranged at the center of the cylinder 12 of the steam turbine, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com